Given the relentless rise in competition across all industries, it is vital to streamline your warehouse operations. Technology offers benefits in this regard that you just can’t ignore. But with so many available software solutions, deciding between them can be challenging.

That is why in this blog, we will be comparing WES vs WMS so you can make the right decision.

We will explain in simple words exactly what these two systems are all about, their relative pros and cons, and the one that will work best for you based on your needs.

Furthermore, we’ll cover the most versatile solution that covers the best of both worlds. This will help you boost warehouse throughput, productivity, and fulfillment accuracy.

Table of Contents

Difference Between WES and WMS

The warehouse management software (WMS) is basically a planning tool. The Warehouse Execution System (WES) executes this plan. So after planning with a WMS, you need a WES to execute this plan.

The key difference between WES and WMS is that WMS forecasts optimal stock levels, tracks inventory movement, and sets operational goals while WES is designed primarily for high-tech fulfillment centers to guide automated equipment, like robots, for instance, to achieve operational goals set by the WMS.

While both systems are designed to streamline warehouse operations, they do so using different methods. Therefore, it is important to understand what exactly each system does so that you can understand its unique benefits.

Warehouse Execution System (WES)

The WES warehouse execution system ensures that your workers and machines work in harmony to fulfill more orders in less time.

It optimizes stock handling, work scheduling, and equipment utilization in a warehouse via real-time coordination. WES systems can optimize warehouse processes, direct automation equipment (for example, robots, sorters, conveyers), and give you complete visibility into all warehouse activities.

The WES can integrate with other warehouse solutions to optimize your warehouse workflow.

A key point to bear in mind is that the WES is basically engineered for high-tech warehouses with automated equipment like robots, sorters, and so on. So if your warehouse uses just forklifts and manual labor, you won’t benefit from a WES.

Warehouse Management System (WMS)

A WMS, is a comprehensive solution for managing and controlling warehouse operations. It covers a wider range of functions compared to the WES.

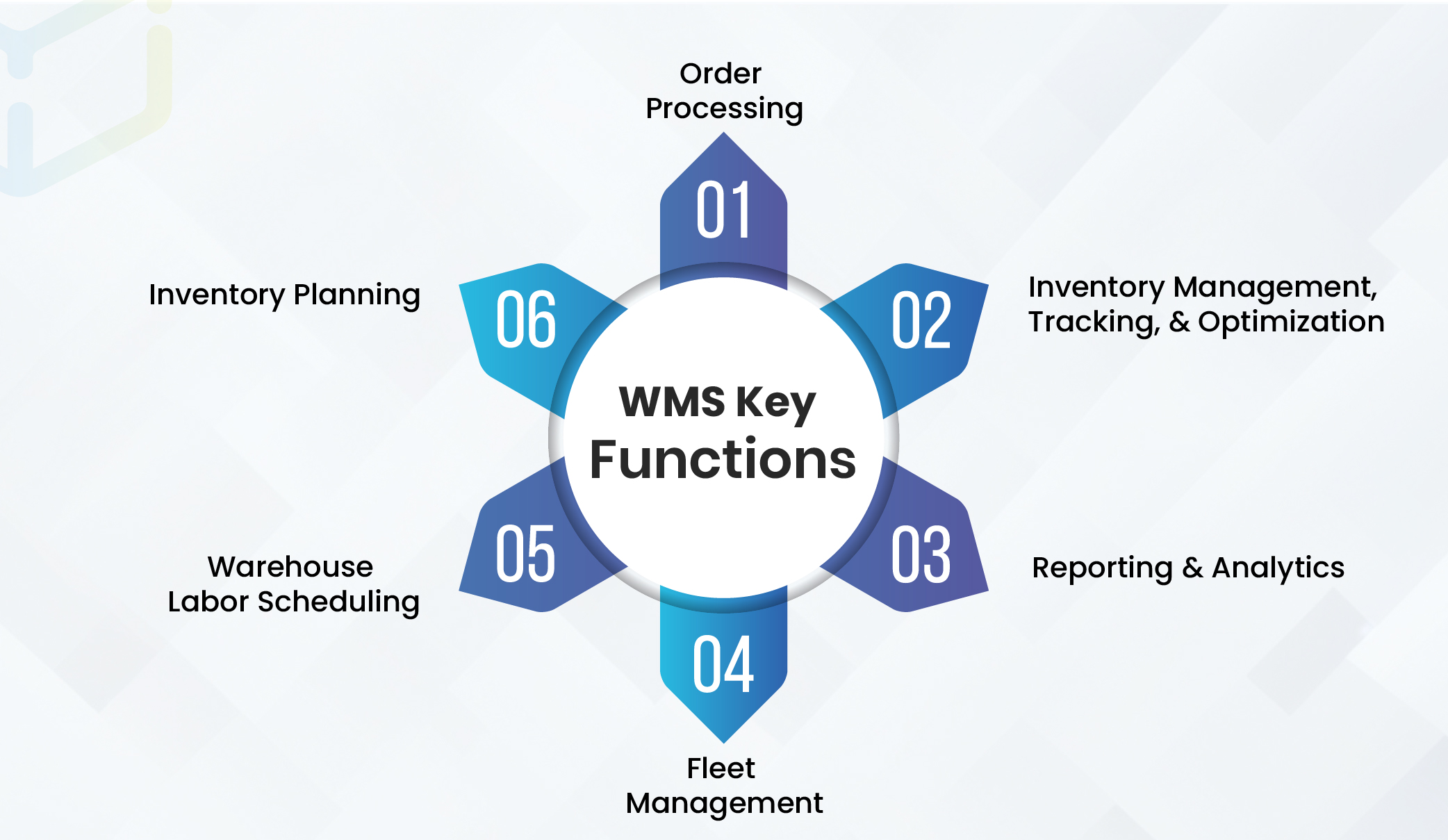

Key Functions of a WMS

The WMS takes care of

- Order processing

- Inventory management, tracking, and optimization

- Reporting and Analytics

- Fleet management

- Warehouse labor scheduling

- Inventory planning

- and all other crucial warehouse activities.

The main thrust of the WMS is to optimize all warehouse activities.

WMS Integrations

High-end WMS solutions can integrate with:

- ERPs (enterprise resource planning software)

- Ecommerce platforms

- Online marketplaces

- Shipping carriers

- 3PL service providers

- and more.

This integration is crucial for expediting order fulfillment, improving productivity, and bolstering supply chain performance.

So, whereas the WES aims to enhance real-time coordination, plus material handling and equipment management.

The WMS, on the other hand, primarily deals with planning key warehouse processes like labor management, order processing, inventory organization, and daily warehouse tasks.

So while there can be some overlap between a WES and a WMS, there are key differences in functionality.

Check out our price plans for the most competitive rates

Check price plans!Key Benefits

WES Benefits

High Operational Performance: The WES accelerates daily warehouse tasks through real-time data. The result is better resource usage, shorter cycle times, and higher throughput.

Enhanced Decision-Making: Since the system provides high visibility into all warehouse activities, managers can make better decisions thanks to real-time inventory data. Access to updated and complete information allows managers to respond effectively whenever the need arises. Disruptions are minimized, and high efficiency is maintained.

Powerful Integration: Integrations enable WES to provide accurate warehouse operations data to other business systems. This reduces the need for manual data entry and minimizes subsequent human errors and delays.

WMS Benefits

Here are the key WMS benefits.

Enhanced Inventory Management: Since the WMS provides access to accurate, updated, and complete real-time stock data, it provides complete visibility into the movement, location, and amount of inventory. This allows better inventory control, higher order accuracy, and fewer stockouts.

Better Management: By providing comprehensive data on inventory in real-time, the WMS gives managers all the data they need to maintain robust inventory control. Real-time data allows managers to make timely decisions to proactively resolve problems before they arise, thereby maintaining high operational efficiency.

Comprehensive Automation: time-consuming and repetitive tasks can be automated to boost speed, accuracy, and productivity. For example, the WMS can monitor inventory so that when it reaches a critical low, the system can send timely alerts. Not just that, it can also reorder and replenish stock automatically. Several other key processes can be automated.

Faster Supply Chain: Improved 3PL coordination, fleet management, and multi-location management, courtesy of a sophisticated WMS, can help you improve the performance of your supply chain. You can ship more goods in less time while improving accuracy.

Better ROI and Higher Order Fulfillment

Both the WES and WMS enable your business to cut costs, raise profit margins, and speed up daily warehouse tasks. You can make feasible data-driven decisions with these tools at your disposal. You can thus enjoy greater cost savings and increased revenue for a higher ROI on these systems.

But do note that the WES brings value only if your warehouse runs on cutting-edge automation equipment. Without such high-tech equipment, there is no need for a WES. A WMS alone will suffice.

WES vs WMS: Which System Do You Need?

No matter what your warehouse type, you will need a robust WMS. There is no way around that for entities that are serious about being competitive.

Hence, a good WMS is not an option if you want to stay relevant in this age of ever-increasing competition.

However, things are a bit different with the WES.

You will need one to complement your WMS if your warehouse runs on high-tech robotic machinery. But without such sophisticated equipment, investing heavily in a costly WES makes no sense.

You will do quite well by choosing an affordable WMS over a very expensive WES.

WareGo provides you with the full list of enterprise-grade features at the most affordable rates. It also offers certain useful features of WES, such as real-time tracking, automation features, and integrations.

Hence, WareGo stands out as the optimal choice if you want to invest in one software that will give you the right blend of features you need to optimize your inventory, warehouse, and logistics.

Our friendly experts will be delighted to explain how WareGo can bring real value to your business.

Start My FREE Consultation!WES vs WMS Comparison Table

Here is a WES vs WMS comparison table that will help you better understand what each system does and how one complements the other.

| Feature | WMS | WES |

| Key Role | Making a plan for warehouse operations. | Executing the plan for warehouse operations. |

| Main Purpose | Outlines high-level strategy and operational goals for the warehouse. | Implements the strategy and specifies instructions to achieve operational goals. |

| Time Scale | Involves longer time scales, eg, waves and batches for order fulfillment | Involves shorter time scales, in minutes or seconds, |

| Main Features | Controlling inventory | Provides instructions to staff and automatic machines |

| Flexibility | Strategy and goals don’t change often. | Fulfillment instructions can change instantly |

| Example Task | “Process all customer orders for product X in 3 hours.” | “Send forklift to pick up X pallets from location Y” |

| Primary Function | Managing all warehouse functions, | Specifying details for warehouse operations. |

| Who Uses It | Managers | Operators |

Is WareGo the right fit for your business? Find out with a 100% FREE trial.

Start My FREE Trial!FAQs

What are WES and WMS?

The WMS is primarily concerned with planning warehouse operations.

The WES (Warehouse Execution System) is focused on executing and implementing this plan.

The key difference is that the WES directs high-tech automated equipment, such as robots, sorters, and conveyers. Hence, if your warehouse does not have such cutting-edge equipment, you won’t need a WES.

Is WMS difficult to learn?

No. While experts were indeed required to operate an enterprise-grade WMS, this is no longer the case thanks to WareGo. The software features a clean, minimalist, and self-explanatory layout that allows anyone, including non-experts, to start using it intuitively. The UI has been thoughtfully engineered to make you productive from the get-go. You can operate most features right away, even without training. Experts and nonexperts alike can effortlessly use our highly inclusive system.

What is the full form of WES in a warehouse?

WES is an abbreviation for Warehouse Execution System. This system is at the core of high-tech warehouses that operate cutting-edge automated hardware for inventory processing.

What are the three types of WMS?

Based on deployment and functionality, WMS can be categorized into the following three types:

Standalone WMS

These are installed on-site for full control but have high upfront costs.

ERP Module

These are part of ERP systems, but since they are not specialized solutions, they may have fewer features.

Cloud-Based WMS

The most popular WMS solution is easy to use, affordable, and feature-rich. Cloud-based WMS WareGo offers enterprise-grade features at the most competitive prices.