With just the license running into hundreds of thousands of dollars, and the annual maintenance fee snowballing into a similar amount, popular systems like SAP can cost you a fortune.

Cost of inventory management software can be exorbitant, to say the least. And that’s no bueno for cost-conscious entities like SMEs.

Thankfully, there is an easy way out for those on a budget. Besides sharing the full gamut of cost drivers (including hidden costs that often take unsuspecting buyers by surprise), we will be sharing a little-known pro-tip so YOU can save big. This is your best bet for enjoying enterprise features without breaking the bank.

So how much should you really expect to pay for affordable IMS software? Without further ado, let’s dive in.

Table of Contents

Key Takeaways

- For budget-friendly solutions: IMS costs are between $50 and $500 per month

- Monthly average cost: around $200.

- MASSIVE cost difference between on-premise and cloud systems

- Prices can vary greatly, so look around

Inventory Management Software Cost Across the Board

The cost lies between $50 per month for budget-friendly options and $500 per month for advanced enterprise-grade solutions. Costs can add up quite fast with advanced features and high functionality. Hence, costs can vary greatly across different IMS vendors. Knowing this is particularly important for SMEs who need affordable solutions.

The monthly average cost of inventory system is roughly $200 per month. This is what we observed through a comparison of over 80 solutions on trusted platforms like Clutch, TrustRadius, and Capterra.

Remember, the numbers mentioned apply to cloud solutions only.

For on-premise solutions, the licensing costs can be much higher.

To gain the perpetual license for your desired on-premise inventory solution, be ready to pay between $30,000 and $100,000. Once again, costs can vary greatly depending on how advanced the features are in your chosen solution.

There are other costs to consider, too. For example, customer support fees can be about $80/month.

Expect to pay at least $800 for customer onboarding. For bespoke systems and third-party integrations, the cost can be much higher. Leading software development firms charge anywhere between $10,000 and $40,000 for such solutions.

In general, with more advanced enterprise-level features, you can expect costs to rise quite sharply.

However, the good news is that you don’t have to pay a fortune for advanced features that automate, optimize and streamline all steps of your inventory operations.

Pro-Tip: The Low-Cost Solution for Advanced Features

The low-cost inventory software WareGo charges just $449 to get started with cutting-edge features like AI tools, automation features, and robust management features that simplify your whole inventory cycle.

For unlimited SKUs, you can opt for the advanced price plan that costs just $1149 per month. Revolutionize your inventory management with the full spectrum of advanced features: Multi-location management, automatic stock reordering, 200+ integrations, and more.

With WareGo, you can enjoy the highest value for money while staying within budget. What’s more, you enjoy cost savings that only cloud technology can provide. The cloud-native platform scales with you as your business grows. No need to invest heavily in costly IT equipment and specialists.

In short, you save costs in many different ways with WareGo while still enjoying the full range of features your business needs.

The pricing model is fully transparent with no hidden fees. The same can’t be said, though, for other solutions that often have a very complex pricing model with hidden fees.

Check out our price plans for the most competitive rates

Check price plans!Inventory Software – the Basics

Inventory software covers all processes in the inventory cycle, like shipping, sales, warehousing, manufacturing, and more. Automation is a core feature of any good IMS. It helps to save time, effort, and money while significantly raising productivity and accuracy.

Real-time tracking is another vital tool that helps business leaders and managers understand the stock counts and movement of all SKUs.

There are many more valuable features, such as.

- Serialization, allocation,

- and tracking of inventory

- Picking, packing, and shipping management

- Automatic invoicing and billing (for both suppliers and customers)

- Sales and returns management

- Multi-warehouse management

- Automated reordering and returns

- Supplier management

and more.

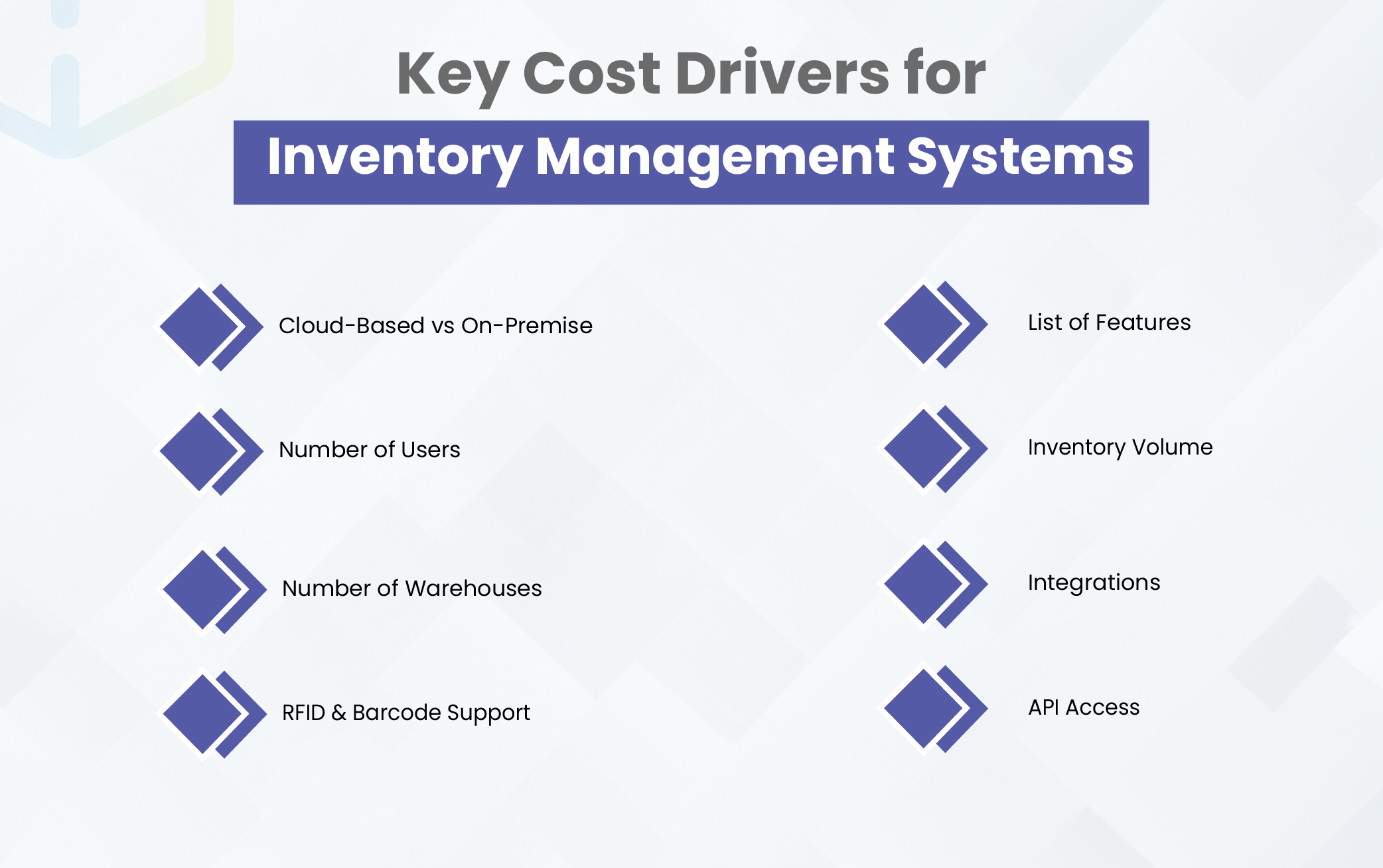

Inventory Software Cost Analysis

Here is a simple yet comprehensive inventory software cost analysis. It will help you to understand the main expenses involved, especially hidden costs.

Cloud-Based vs on-Premise

Cloud-based solutions are far more affordable since you don’t have to invest upfront in costly IT equipment. You also don’t need to hire a full-time staff of experts to run such equipment. Also, the licensing costs of on-premises can be massive, to say the least. So, cloud-based platforms are, without doubt, a cost-effective and economical solution compared to on-premise software.

List of Features

Features, functions, and modules can extend the functionality of your software so that it better serves your needs. However, that comes at a price, particularly the advanced features.

Number of Users

The monthly subscription cost is for each system user. So you should multiply this amount by the total number of users you plan to onboard.

Another thing to note is that many basic plans have a cap on the number of users. Once you exceed this limit, you will have to upgrade to the higher-tier plan.

Inventory Volume

More SKUs translate to greater costs. Basic plans often have a limit on SKUs, which may suffice for smaller firms. But a growing business may likely exceed this limit, whereupon it will need another plan with a higher SKU limit, for which the cost will certainly be more.

Number of Warehouses

The basic plan will limit how many warehouses you can operate with it. When your business exceeds this threshold, you will have to upgrade to a costlier plan that allows more warehouses.

The Number of Integrations

Integration matters since it is vital for synchronizing your inventory data with the rest of your business tools, like ERP, CRM, accounting, e-commerce platforms, and others. Hence, you should choose an IMS that offers plenty of integrations out of the box, like WareGo, which has 200+ integrations.

If you require an integration not provided by your IMS vendor, you will have to pay a third party to do it. However, it will not come cheap, especially if you hire reputable software developers.

RFID and Barcode Scanning Support

RFID and barcode scanning support is vital for fast daily operations. However, it comes at a price.

API Access

This is necessary for a system that does not provide out-of-the-box integration. While API access can sync this system with your IMS and thus greatly boost its functionality, you will have to pay extra.

Security

Robust industry standard security protocols and regulatory requirements also determine IMS costs.

Get your free demo to see our cutting-edge platform live in action.

Start My FREE Demo!Hidden Costs to Watch Out For

Here are the hidden costs that are often not mentioned in complex pricing models. So make sure you note them all down and discuss them in great detail with prospective vendors.

Level of Customization Required

More complex operations may require a higher level of customization. You may need customization since it better aligns the software with your processes. How much you pay depends on how complex the customization is.

Onboarding Costs

The onboarding process involves basic configuration, setting up user accounts and permissions, training your staff to operate the platform efficiently, and providing support services from onboarding experts.

Depending on the vendor, the onboarding fee may be specified separately or it may be included in the subscription amount.

Implementation Costs

The implementation phase can last a few weeks at least. Whether you complete this phase with the IMS vendor or a third party, you are often required to pay a fee. But WareGo does it at no extra charge.

Implementation takes care of testing the IMS platform for reliable operation, configuring the system to match operational processes, developing custom dashboards and features, integrating your existing business systems (like ecommerce platforms, POS, barcode scanning, accounting, CRM, ERP and so on), and migrating data related to your suppliers, purchases, sales and so on.

Customer Support Costs

The basic plan may not always include customer support costs. You could be charged separately for costs pertaining to upgrades, data storage, technical assistance, and customer support.

Since this cost is highly variable for different vendors, specifying an average is not feasible. Even if support is included in the basic plan, you may need to opt for a more advanced plan for a support service that better suits your growing needs.

Thankfully, WareGo does not charge extra for 24/7 expert customer support.

Additional Software Costs

While IMS can cover quite a bit, it is a highly specialized solution for inventory, and thus it can’t do the work of, say, a CRM (customer relationship management) system.

So when selecting the right IMS, it is also advisable to consider any other software necessary for your unique business requirements. You might need accounting software, finance, e-commerce, and HR solutions.

This approach may be more flexible and better for your needs than an ERP, which hardly provides any flexibility with its fixed offerings.

Other Costs

Other costs might include training, system configuration, data migration, and consultation costs.

Is WareGo the right fit for your business? Find out with a 100% FREE trial.

Start My FREE Trial!Choosing the Best Inventory Software for Your Needs

With the right IMS, you can effortlessly streamline your daily operations and take your business efficiency to new heights. However, choosing the best IMS for your needs is paramount. Here is how you can do it.

1. Evaluate Your Business Requirements

Make a list of all your basic requirements. You will need to think about key matters like inventory volume, industry-specific needs, and your logistics complexity. Assessing these factors will help you understand what you really need.

2. Make a List of Key Performance Indicators (KPIs)

Listing and recording your KPIs is essential for understanding your operational performance. These KPIs can help you understand how well your business is performing with the new IMS at its core. Note down key parameters like stockout frequency, order accuracy rate, inventory turnover, and the like. You will want all these key metrics to be included in your desired IMS.

3. List Down Software Features

Certain features are a must-have, like tracking inventory in real-time, AI-powered smart forecasts, automated reordering, and so on. Note down these essential features and stay with them. Your chosen solution should have all of these features. Avoid getting sidetracked into paying for unnecessary features.

4. Think About Scalability

You want a system that grows with your business. On-premise solutions are very hard to scale, besides being very costly. Cloud-native solutions are a much better option since they scale effortlessly with their flexible architecture. Plus, they cost far less upfront.

5. Consider Integration

Make a note of all business tools you are using. This could include CRM, e-commerce platforms, accounting software, and so on. Your chosen software should sync with these seamlessly for highly efficient automated operations. If an integration is not available, you may need to pay a third-party provider for the integration.

6. Analyze All Costs Involved

You should discuss in great detail the costs involved with prospective vendors. We have shown you a comprehensive list of costs, many of which tend to be hidden. So you should discuss these costs upfront and ask them to specify clear amounts for each cost driver.

This way, you won’t be set back with hidden costs, which can be quite high.

7. Try Out the Software

Many vendors frequently offer free demos and trials. So make sure you avail these. Through trials and demos, you can gain hands-on experience that will better help you understand the suitability of systems you are considering. Make sure the software meets all requirements and performs according to your expectations.

8. Onboarding, Support, and Implementation

The vendor should preferably provide 24/7 customer support. They should also handle all steps involved in onboarding and implementation, which we explained in detail. They should provide comprehensive resources for training so your staff can become productive soon.

9. Getting Started

There are certain things to take note of before you can get up and running with your IMS. These include considering:

- The number of users for your system

- All your business software solutions that need integration with your IMS

- Your hardware with which you will be running the software (like mobile devices, laptops, printers, and barcode scanners).

The best way to go about it is to get in touch with your IMS vendor for smooth implementation and onboarding.

Do I Need an IMS for My ERP System?

An ERP system is a massive software suite that aims to provide the full list of features and functions that an enterprise needs for all its departments. Inventory management is just one component in an ERP.

Initially, it may seem that a standalone IMS is not necessary for an ERP.

However, there is one problem with ERPs. Since these are all-encompassing suites, instead of specialized tools, their inventory component can’t provide the same level of advanced functionality as standalone inventory systems.

So even with an ERP, a big enterprise may still consider acquiring an IMS to manage complex inventory in a better way.

The good news is that WareGo integrates nicely with well-known ERPs such as SAP and Microsoft Dynamics. Integration capability matters a lot since the IMS must freely exchange data with your ERP to function seamlessly.

Bottom Line

You are now well aware of the cost drivers that determine the total cost of your intended IMS.

It is advisable to try out WareGo since this highly trusted and proven platform keeps costs to a minimum while providing the full gamut of all necessary features you will ever need. The software has been designed based on the practical needs of businesses across all industries. So you can’t go wrong with a system engineered to excel and perform well for businesses of all types.

With WareGo, you can enjoy much-needed features that will take your inventory management to a new level, like automatic reordering, low stock alerts, real-time inventory tracking, and so on. Thanks to multi-location management and omnichannel support, you can manage inventory across multiple warehouses, distribution hubs, and ecommerce platforms hassle-free. Instant reports and in-depth analytics offer profoundly valuable insights that will help you earn more, save costs, and grow your business.

There are more than 200 integrations with WareGo. So there is a good chance that your favorite business tools are included.

The cloud-based platform scales effortlessly with your business. You save huge amounts with cloud technology since you don’t have to buy costly IT equipment, hire full-time specialists, or purchase software licenses that cost you an arm and a leg.

You don’t have to sign a long-term contract, nor deal with complex pricing models. You won’t be hit with hidden costs.

So you should wait no longer.

Reach out to our friendly experts who will be more than pleased to give you a consultation.

Our friendly experts will be delighted to explain how WareGo can streamline your business.

Start My FREE Consultation!FAQs

How much does inventory software cost?

Inventory software costs can be highly variable. In general, cloud-based solutions are much cheaper than on-premise solutions. With trusted cloud platforms like WareGo, you pay just $449 per month for an enterprise-level IMS – this is much cheaper than prohibitively expensive on-premise solutions that require hundreds of thousands of dollars in upfront investment.

What is the average cost of inventory software?

The average cost per user per month for IMS systems is around the $200 mark. So you should multiply this by the number of users to get a ballpark estimate. Some IMS solutions have a low price tag, but they are often lacking in key features. WareGo gives you the full spectrum of necessary features at the most competitive rates.

What is the best inventory software for a small business?

Zoho, NetSuite, Fishbowl, Cin7, and Sortly are extremely popular inventory solutions. However, WareGo is a rising star in the competitive world of IMS suites that offers, by far, the best blends of useful features at knockdown rates. You will be hard-pressed to find better value for money anywhere else.

What is inventory management cost?

Inventory management cost includes the inventory purchase price, costs incurred from inventory storage, warehouse depreciation, stockout costs, warehouse labor costs, and so on.