Warehouse layout optimization is critical for fast, accurate, and efficient operations. A properly optimized warehouse allows the business to save costs, improve service quality, and drive sales. Deploying a powerful warehouse management software is crucial for fully utilizing your limited warehouse space.

Our friendly experts would be pleased to explain how WareGo streamlines operations.

Start My FREE Consultation!Table of Contents

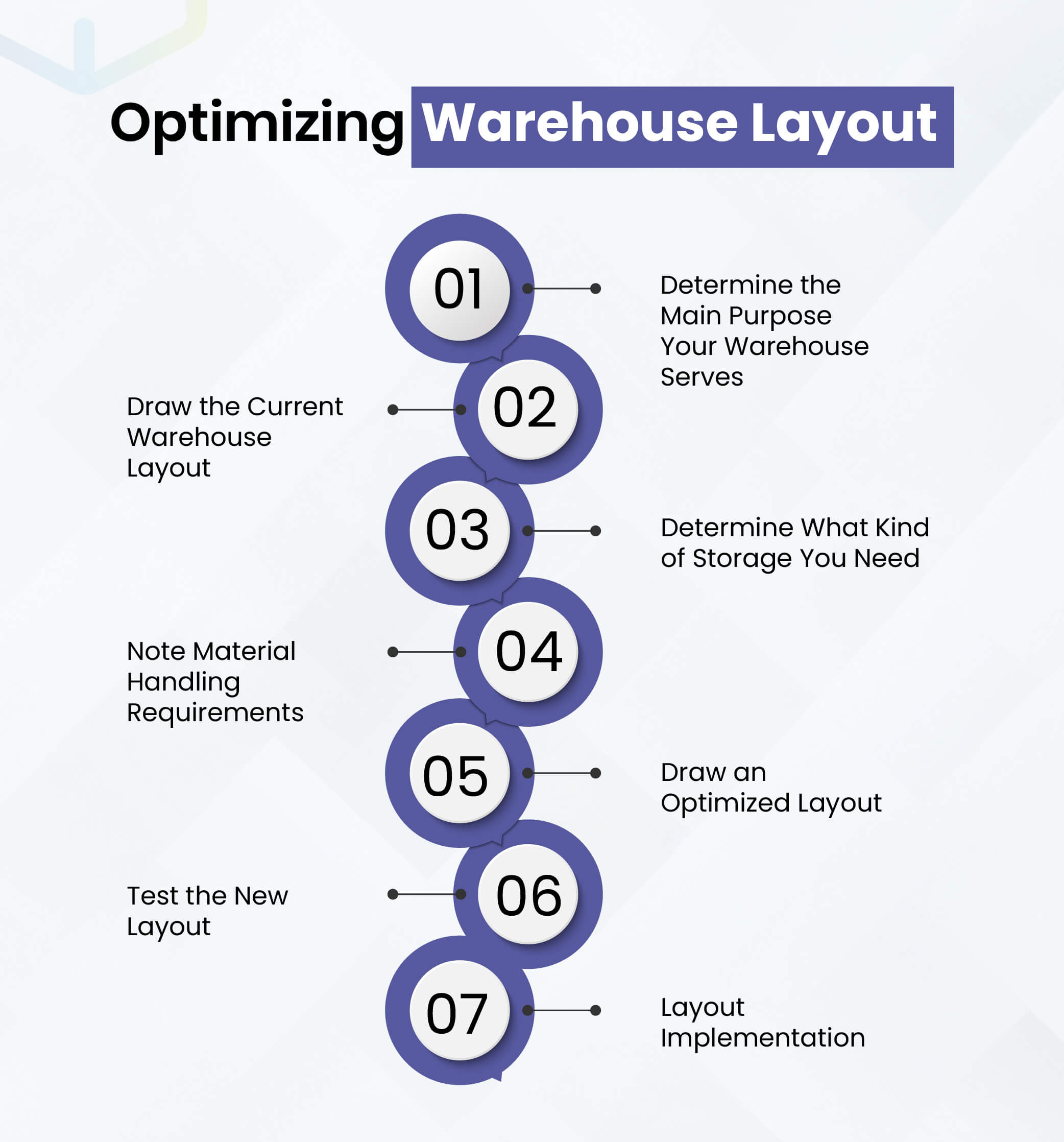

Optimizing Warehouse Layout

Optimizing the warehouse layout for high efficiency is the need of the hour for entities serious about raising productivity. Here is how it can be done.

Determine the Main Purpose Your Warehouse Serves

Make a list of all the key objectives your warehouse must serve. Also, factor in the business model to understand the nature of your operations.

Different warehouses serve different purposes depending on the business model. For example, a manufacturing concern’s warehouse is primarily meant to ensure a steady supply of materials for production. On the other hand, a distribution center fulfills orders to deliver the right items on time to customers and retail outlets.

Keeping the primary purpose in mind lets you optimize the warehouse layout so that it works best for your particular business model.

Draw the Current Warehouse Layout

A simple 2D diagram can represent your warehouse space. You can use specialized software if you like, although grid paper is enough for the task.

Once you draw out the warehouse floor, it is time to estimate the available space. You will also need to know the height to assess the available volume. Be sure to deduct the area occupied by places like offices, washrooms, boiler rooms, and the like, which can’t be used for storage.

Finding out the available volume is a key step in optimizing your warehouse space.

Determine What Kind of Storage You Need

What kind of storage equipment will work best for your warehouse inventory? So you need pallet racks, shelves, a mix of both, or something else? Do you need bins for your items, and will you need to stack items?

You should also know the average inventory volume available at any given time. You can use your WMS for this purpose.

Now compare the inventory volume with your available warehouse volume. This should give you a fair idea of how much spare capacity you really have in your warehouse.

You will also gain a better understanding of the best way to store products.

Our friendly experts can show what WareGo does for our clients.

Chat With Us!Note Material Handling Requirements

Based on your inventory type, you can determine what kind of item processing equipment works best. Do you need a simple forklift and a pallet jack? Or will more sophisticated equipment, such as AS/RS, conveyors, and carousels, be required for your stored items?

While such equipment can significantly speed up operations, it does occupy space. For example, forklifts can occupy quite a bit of space. Hence, you will need to keep this in mind when working out what equipment you need.

Draw an Optimized Layout

You can now map out the optimized warehouse space, taking into account the business model, goods movement, available storage space, and the information mentioned above. For this purpose, you can use either specialized software or grid paper. Using one of these is necessary since the objective here is to optimize warehouse space; hence, you will want to maintain good accuracy.

Take a look at the warehouse space and pay special attention to the flow of goods. See how goods move when they are received, all the way to the shipping section. There should be no hindrance or bottlenecks that can slow down movement.

Test the New Layout

The new layout should be tested. With masking tape, you can mark out walking areas and pathways. Try driving forklifts and moving pallets and boxes around to see how it works out in practice. There should be enough space for safe and efficient movement. Note down all observations for possible hindrances and bottlenecks. These should guide the placement of equipment, racks, shelves, and so on.

Layout Implementation

You can now place all the racks, shelves, equipment, and other assets in their respective locations according to your newly designed layout. Use clear signs to indicate all paths and routes in your warehouse. Place all inventory items logically so that your staff can pick them easily in less time. Ensure proper labelling so that all items can be located quickly without hassle.

Safety training is essential for compliance and a good working environment. Outline a maintenance and cleaning schedule to keep the facility in excellent condition.

Warehouse layout optimization does not stop here. You will need to periodically review the warehouse floor to identify new requirements, possible bottlenecks, and room for improvement. In case your business model evolves or operations expand, you will have to refine the warehouse space accordingly.

See our cutting-edge platform live in action.

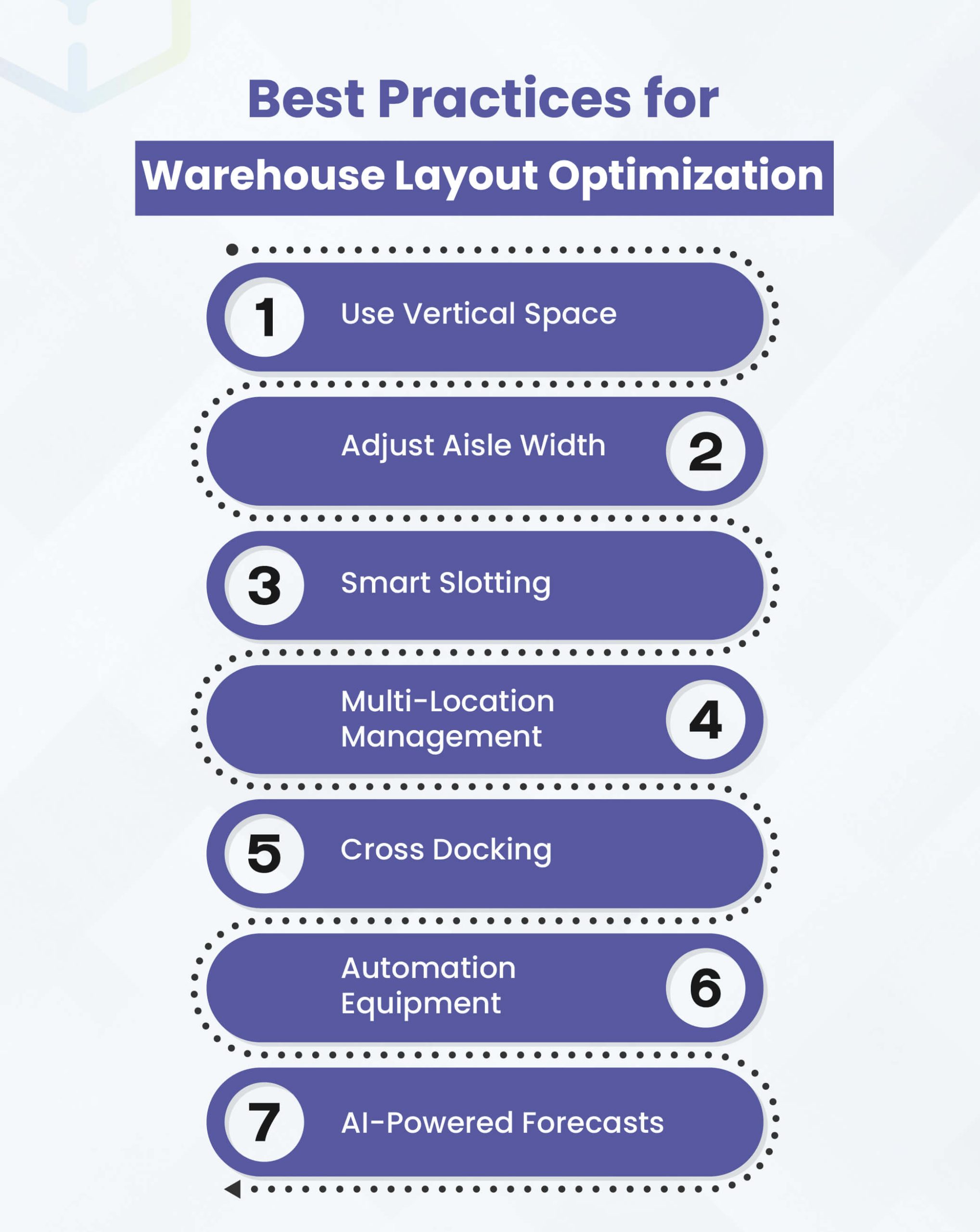

Start My FREE Demo!Best Practices for Warehouse Layout Optimization

Here are the best practices for warehouse layout optimization that will take operational efficiency to the next level.

Use Vertical Space

This strategy is beneficial if you are running out of empty floor space in your warehouse. The vertical space in your warehouse is a key asset for your business that you should definitely utilize.

You can do that by installing mezzanines and multi-level shelves. Through the right storage equipment, you can store more inventory in the same area.

Automated storage and retrieval systems allow quick retrieval for items placed high. Besides saving time, it also reduces the workload for your staff.

An enterprise-grade WMS can also help you make the most of your vertical space by telling you what products to store higher and when to do it.

Adjust Aisle Width

Wide aisles allow for quick and safe movement. However, narrow aisles will enable you to store more inventory. Hence, you must strike the right balance between the two to optimize your warehouse.

How optimal aisle width depends on inventory and equipment used. Turret trucks can make narrow aisles more feasible.

Smart Slotting

Smart slotting is at the core of an efficient warehouse. It refers to putting the right items in the right place at the right time to facilitate quick and accurate picking. Slotting done right can significantly reduce worker travel time thereby speeding up order fulfillment.

Intelligent product placement by means of a robust WMS like WareGo enables you to optimize your warehouse space.

For example, WMS with built-in ABC classification can identify fast and slow-moving goods. You can thus place fast-moving goods closer to workers and slow-moving goods deeper inside the warehouse to reduce the average travel time for your staff.

Is WareGo the right choice for you? Find out with a 100% FREE trial.

Start My FREE Trial!Multi-Location Management

Managing multiple warehouses and distribution centers can be pretty complex. Once again, a good WMS will give you the visibility and tools you need to simplify multilocation management. Besides managing your warehouses with efficiency, you can also streamline your supply chain with specialized software.

Cross Docking

Cross-docking involves shipping inventory immediately as it is received. The goal here is to reduce storage time or to minimize items stored so that inventory holding costs go down. This can work quite well for high-throughput warehouses that deal with fast-moving goods.

Cross-docking clearly requires timely and accurate inventory delivery for it to work. This is possible only if there is strong collaboration with your 3PL partners via real-time software.

Automation Equipment

Cutting-edge warehouse hardware, like automation equipment, can significantly speed up order processing and precision. You can upgrade your existing warehouse space by placing ASRS, robotic pickers, conveyors, and other such equipment to reduce manual work.

Such equipment is ideally suited for repetitive tasks like picking and sorting. For instance, you can use conveyors to move goods across your warehouse. Labor productivity can rise significantly with the right equipment.

AI-Powered Forecasts

Maintaining lean inventory levels is vital for efficient warehouse operations. There should be just enough inventory to fulfill demand, but not any more than this optimal level. Excess inventory leads to overstocking, which will consume your valuable warehouse space and significantly raise costs.

Accurate forecasting is vital for preventing overstocking as well as stockouts. It is easier said than done, though. Forecasting is effort-intensive, time-consuming, and often imprecise.

AI-powered forecasts can provide an accurate picture of demand. They significantly reduce the time and effort managers put into the forecasting process. WareGo deploys intelligent algorithms to make the most accurate forecasts.

Takeaway

The best practices and strategies explained above allow you to streamline your limited warehouse space. In particular, specialized warehouse systems like WareGo are ideal for optimizing your warehouse floor without costing you a fortune.

Our enterprise WMS offers the most competitive rates.

Check price plans!FAQs

What is warehouse layout optimization?

Warehouse layout optimization is all about planning and arranging the warehouse floor to accelerate warehouse operations. The warehouse floor is optimized to remove all possible bottlenecks and hindrances to the movement of workers and inventory. This can be achieved in different ways. For example, fast-moving goods are placed near aisles to speed up picking. Height may also be utilized to increase storage capacity by using higher shelves. High-demand items may be placed nearer to packing stations for fast processing.

How to optimize your warehouse?

There are many ways to optimize the warehouse. For example, crossdocking can be implemented to immediately ship fast-moving items when they are received. Slow-moving items should be placed further away from main paths, while fast-moving goods should be placed near main paths to reduce average travel time. There should be separate paths for forklifts and workers to improve safety and prevent traffic slowdowns. Logical arrangement of items can also speed up picking, for example, by placing similar goods in one zone for easy pick up. There are many more best practices besides warehouse optimization.

What is the best warehouse layout?

The best warehouse layout depends on the business model and daily activities. What may be an optimal design for one business may not necessarily be the best solution for others. For example, crossdocking may be the optimal solution for companies that deal in FMCG (fast-moving consumer goods). Here, goods are loaded onto waiting outbound trucks as soon as they are received, for which the receiving section is located next to the shipping area. Such an arrangement, while optimal for FMCG sellers, will definitely not work for manufacturing concerns. Hence, all businesses need to optimize as per their business model and nature of operations.

What are the most widely used warehouse shapes?

The most widely used warehouse layouts are designed for cost saving, inventory type, order volume, safety measures, and business model. The U-shape layout is the most versatile since it suits a wide range of business models. I-shape layouts work best for high-throughput operations, especially where conveyors are installed. An L-shape layout is suitable for controlling the flow of traffic and managing the movement of larger items.

How to assess the effectiveness of warehouse layout optimization?

Good question. Accurately assessing the effectiveness of warehouse layout optimization can show the success rate of your improvement efforts and point out room for improvement. Here are factors you can monitor to assess how your optimization effort is faring.

- Order fulfillment rate

- Inventory level accuracy

- Fulfillment rate, for example, items picked per hour

- Shipping and receiving efficiency

- Storage capacity utilization

- Cost per order

Before you carry out warehouse optimization of any kind, first find out what the baseline values are for these KPIs. Also, be sure to include other relevant KPIs where necessary.

How to increase the storage capacity of your warehouse?

To increase the storage capacity of your warehouse, you can use the right storage equipment that uses height to your advantage for increased storage volume. Install shelves and racks that store items at higher levels. Also, be sure to look for areas that are underutilized and find ways to make better use of these underused places. Reduce the aisle width if it does not impact safety and traffic flow. Remove any obstruction or bottleneck that slows down the movement of goods and workers.