Warehouse efficiency is not just an option – it is an absolute necessity. The importance of warehouse efficiency comes to the fore when even a single delayed order results in a lost customer.

In today’s highly competitive environment, there is simply no room for inefficiency of any kind. High efficiency or the lack thereof can be the big difference between thriving and going under.

The most recognizable brands give top priority to warehouse efficiency, optimizing all steps of warehouse operations from receiving purchased goods to shipping orders.

We will cover some of the best proven techniques for bolstering efficiency. These tips and tricks can add up fast to give you a significant overall improvement in operational speed. You can thus gain a decisive edge over the competition.

Table of Contents

Warehouse Efficiency Explained

Warehouse efficiency describes how well a warehouse executes its routine processes. All processes must be done rapidly and accurately.

To do this, warehouse managers must focus on utilizing labor, inventory, equipment, and warehouse space in the best possible way. In particular, it is important to use a trusted all-in-one WMS at the core of all warehouse activities to achieve high precision, lower costs, and faster order fulfillment.

Even simple things like implementing barcode scanning and better use of limited warehouse space can significantly boost your workflow.

With smart yet simple improvements, you can accomplish more with less work – this is the goal of warehouse efficiency.

Pro-Tips for Warehouse Efficiency Improvement

Small improvements can lead to major gains in operational speed and precision. Here are the best warehouse efficiency tips for warehouse efficiency improvement to bolster productivity across the board.

1. Improve Your Warehouse Layout

Enhancing warehouse layout can greatly improve storage space and boost labor productivity.

Here is what you can do:

- Redesign the warehouse floor for shorter travel times and easy access.

- ABC classification helps you identify fast-moving goods that should be placed within easy reach of your workers. This reduces overall travel time and improves picking speeds.

- Inventory management techniques like slotting and serialization can help you organize inventory for faster picking.

ABC classification, slotting, serialization, and other advanced inventory management techniques are fully supported by dependable WMS solutions like WareGo.

Get your free demo to see our cutting-edge platform live in action.

Start My FREE Demo!2. Go for the Lean Approach

The lean approach is a proven strategy for speeding up operations, cutting costs, and improving profit margins. It involves cutting out anything that is nonessential, as this leads to waste. This method is based on the 5S technique:

- Sort

- Set (in order)

- Shine

- Standardize

- Sustain

The 5S method can help raise efficiency and cut waste.

Maintaining lean inventory levels is now simplified thanks to powerful WMS solutions that use AI-powered tools to study previous demand and suggest optimal stock levels.

3. Automate Labelling

Accurate inventory labelling is necessary for tracking inventory movement and accelerating warehouse workflows.

RFID/barcode scanning can greatly speed up locating and identifying necessary items.

In addition, properly installed signage can help workers navigate faster by pointing out storage spots, racks, and aisles that workers need to find.

Signs and labels can optimize both your inventory and the warehouse floor.

4. Expedite Order Picking

You can streamline item picking for faster order fulfillment by prioritizing orders according to volume and type of product.

Waves: Several orders can be combined into “waves” for faster picking and fewer errors.

Waveless Picking: In the case of low order volume or costly products, it may be feasible to execute one order at a time.

Batches: Grouping orders in small batches can help ease congestion along storage aisles and packing stations.

Zones: Allocate zones to specific groups for shorter travel time and faster picking speed.

Discrete Picking: Specific products and whole orders can be processed according to order requirements.

You can schedule waves, batches, and other picking operations with ease thanks to enterprise-grade inventory solutions.

5. Digitize Your Warehouse with a Reliable WMS

A field-tested WMS solution like WareGo can help you immensely with key elements of warehouse management like task scheduling, inventory organization, multi-location monitoring, and more. To scale operations, manage more SKUs, and increase orders, a WMS is an absolute must-have. A modern WMS will have AI-powered tools for accurate demand forecasting – a process vital for maintaining lean inventory levels.

The WMS will provide a long list of useful features like real-time inventory monitoring, automatic stock replenishment, omnichannel support, and integrations that can help your business thrive.

The warehouse management system lets you keep track of several key metrics and gives you access to deep analytics and instant reports from which you can gain valuable insights for good data-driven decisions.

Is WareGo the right fit for your business? Find out with a 100% FREE trial.

Start My FREE Trial!6. Higher Labor Productivity

Enhancing labor productivity should be a top priority for warehouses of all scales. This is because labor costs constitute a huge chunk of warehouse costs. Also, labor productivity directly influences order fulfillment speed and precision.

There are several ways to boost labor productivity. You can track KPIs and certain metrics to understand how individual workers are performing. However, following these figures can be hard without a WMS.

Key KPIs include pick rate – this is the number of ordered items picked each hour. Another one is dwell time, which represents idle time. Utilization rate is another key metric that shows the percentage of total time spent doing work.

Studying these metrics can indicate what is needed for higher labor productivity. It could be more training, better equipment, or an improved inventory layout.

Also, intelligent work scheduling arranges tasks for the warehouse staff, enabling quicker processing. This can be done effortlessly using a comprehensive WMS.

7. Study Analytics and Reports

Data analytics from a powerful reporting and analytics suite lets you track important warehouse KPIs like cycle time, order accuracy, and inventory turnover. Following these numbers is essential for understanding whether or not your improvements are translating into tangible results.

Demand forecasting becomes much easier when you have in-depth analytics for analyzing previous demand patterns. This helps you maintain lean inventory levels that minimize the risk of stockouts and overstocking.

8. Cross-Docking

You can free up warehouse storage space via cross-docking. In this procedure, goods received go directly to shipping points instead of storage. This allows faster shipment and fulfillment while freeing up storage space. This may be feasible for fast-moving goods in particular.

9. Install Automation Hardware

Automation is emerging as a major disruptive force that is revolutionizing supply chains and logistics across the globe. According to G2, the worldwide warehouse automation market is expected to reach $30 billion in 2026.

You can install cutting-edge automation equipment like automated guided vehicles, robots, electric monorail, and conveyors to accelerate fulfillment, reduce human labor, and cut costs.

Besides hardware, software automation is also playing a key role in bolstering productivity. Integrations, automatic stock replenishment, barcode/RFID support, automated payments, billing and invoicing, as well as other sophisticated WMS features, are making all the difference for its users.

Download our free warehouse automation guide to help you modernize your warehouse operations!

10. Use Ergonomic Tools

Ergonomic equipment for your workers can make working conditions much better, safer, and more comfortable for your staff. This can reduce churn and thus help you retain more of your experienced professionals. Retaining your best professionals is vital for improving warehouse efficiency.

11. Organize Inventory with Slotting

Slotting enables you to intelligently store your inventory for faster retrieval. This technique is based on analyzing storage space, demand patterns, and product characteristics. You can factor in demand, weight, and size of your products for optimal storage that facilitates reduced travel time and faster picking.

For example, heavier products may be stored closer to material handling equipment for faster picking. While at the same time, lightweight fast-moving goods may be kept close to the main warehouse paths for faster picking.

All-in-one inventory solutions have built-in support for smart slotting and many other features for intelligently organizing your inventory.

Our friendly experts will be delighted to explain how WareGo can bring real value your business.

Start My FREE Consultation!12. Maximize Cubic Space

While the square footage matters a lot, the total warehouse volume is also critical. That is, you should consider placing more shelves or racks above preexisting ones to maximize storage space. For example, automated vertical lift modules can improve storage density by storing items at higher levels.

13. Set Up a Robust Quality Control Process

You can implement a stringent quality control process to reduce errors, product returns, and negative customer feedback. Make sure that strict checking is in place to fully inspect the accuracy, condition, and quantity of both received goods and shipped items.

Before items are shipped off to customers, they should first go through a comprehensive checklist that ensures correct order fulfillment.

Warehouse managers need to regularly review quality control data to find opportunities for improvement, recurring problems, and trends. They can then take appropriate remedial action based on this information.

It is necessary to collect feedback from key stakeholders like customers, warehouse staff, and supply partners.

A lot of this quality control data can be collected, stored, and organized in a comprehensive WMS solution like WareGo.

14. Accurate Demand Forecasting

To make accurate demand forecasts, you need to factor in seasonal variations, consumer trends, and market conditions. Going through previous demand patterns is vital.

This process is crucial for determining optimal inventory levels that avoid stockouts, overstocking, and associated high costs.

In addition, there are external factors to take care of when forecasting demand, like competitor activities, industry innovations, and economic conditions. Including these factors in your demand estimations will lead to more realistic figures for optimal inventory levels.

Peak seasons strongly influence demand and are thus central to the inventory planning and demand forecasting endeavour. Festive seasons often result in peak demand for many goods. You should stay ready to capitalize on increased sales during these seasons. You will thus be able to fulfill customer demand without running into stockouts or a large volume of unsold goods.

Accurate demand forecasting is much more precise and easier when you have a modern WMS that has AI-powered tools to do the job for you quickly and effortlessly. The system can adjust stock levels according to key factors like demand variability, customer preferences, and seasonal trends.

Check out our price plans for the most competitive rates

Check price plans!15. Cut Costs with Just-in-Time Inventory

As the name suggests, just-in-time inventory helps you stock the right volume of inventory at the right time. You can thus eliminate high holding costs, prevent excess unsold goods, and free up more funds for better cash flow.

With the JIT procedure, you can order and keep stock only when required, hence reducing storage costs considerably.

It should be obvious that successful JIT implementation requires seamless coordination with your supply chain partners. This way, you can synchronize goods receiving with your manufacturing schedules or customer order fulfillment.

While this method works well for reducing warehouse storage space requirements, it also raises dependence on suppliers. Hence, this method is feasible only if you have access to trusted partners via a high-performance 3PL management system.

16. Benefit from Cross-Functional Teams

Cross-functional collaboration can help improve inventory planning. For example, your sales team can give you crucial insights concerning customer preferences and market movement. This lets you make better procurement decisions, besides improved planning for inventory.

Cross-functional collaboration with the procurement team can yield valuable insights into customer preferences, which can inform your demand forecasts.

So with deeper cross-functional coordination, you can bolster warehouse productivity and fulfill customer demand with greater ease.

17. Consider Vendor-Managed Inventory

Vendor-managed inventory is a strategic partnership with suppliers where you hand them full responsibility for running your warehouses and inventory. Hence, your supply partners monitor and restock depleted inventory where required in your warehouse.

A WMS solution with powerful 3PL collaboration and real-time stock tracking features can be the perfect tool for such inventory management. Suppliers can gain necessary data directly from the WMS to schedule procurement and shipping at the right time. The business benefits from reduced burden, fewer overheads, and higher expertise from supply chain specialists.

18. Target Omni-Channel Fulfillment

Target multiple sales channels to find more customers. You can go for ecommerce platforms, physical storefronts, social media, and online marketplaces to sell more goods.

By selling more, you can achieve economies of scale and thus increase warehouse efficiency.

You can implement a powerful order management system to sync inventory effortlessly across all sales channels. The system enables you to gather customer orders from all channels into one consolidated system. You will not have to deal with orders separately on different platforms. This reduces the risk of delays, duplication, and errors in processing customer orders.

Omnichannel fulfillment is one of the key features of premier order management solutions like WareGo.

19. Motivate Staff with Incentives

Financial incentives, promotions, and formal recognition can inspire higher motivation in your workforce, thereby raising warehouse efficiency. A performance-based rewards program can boost worker productivity and drive continuous improvement in your warehouse.

You can provide incentives for individuals as well as teams using KPIs as targets, like inventory turnover, picking speed, and order accuracy. This will motivate your workers to widen their skillset, improve performance, and undertake further training to do the job well.

20. Leverage Real-Time Tracking

Real-time tracking via RFID technology maintains complete visibility over inventory movement inside the warehouse. You can attach RFID chips to any asset, pallet, or stock item and install receivers at appropriate distances to pick up RFID signals. An inventory management system with built-in support for RFID technology can help you gather, organize, and process this data for valuable insights into your inventory.

This data can help you optimize routes, prevent theft, and reduce errors, among several major benefits.

21. Perform Frequent Audits

Regular audits in your warehouse are vital for good operational performance. They can reveal hidden bottlenecks, safety problems, inefficient processes, and several other problems that may remain unnoticed for long time scales.

Auditing can take into account key factors like safety compliance, equipment condition, process efficiency, inventory count accuracy, and more to make good decisions that will transform warehouse operations.

For example, inventory miscounts may lead to errors and delays in order fulfillment but may remain unnoticed until an audit is performed to count inventory and compare it with available data.

Hence, it is easy to understand how well-timed audits can revolutionize warehouse performance to achieve operational excellence.

22. Embrace Mobile Technology

Warehouse staff are always on the go and hence need something better than fixed workstations. Tablets, scanners, smartphones, and other mobile devices can provide real-time data on inventory, order status, and more with mobile-friendly apps.

Hence, high-performance warehouses must invest in such devices to avoid unnecessary travel to and from fixed workstations, reduce paperwork, and make their team truly mobile and agile.

For example, warehouse staff may simply do a quick scan with a handheld device to update order status and inventory level instead of going all the way to their workstation for the same update.

Hence, this can result in expedited processes, improved communication, fewer errors, and fewer delays. For fast-paced environments like busy warehouses, mobile functionality is more than just a convenience. It is the need of the hour for mobile teams.

The WareGo warehouse management system has a highly intuitive, mobile-friendly interface that busy professionals on the move can start using right away with little or no training.

Our friendly experts can explain how WareGo helps.

Chat With Us!23. Establish Standard Operating Procedures or SOPs

Standard operating procedures matter since they lead to highly consistent processes that always provide high-quality results. SOPs also reduce errors, delays, and confusion.

With SOPs implemented across the board, be it the receiving dock, shipping station, or any other, processes are executed in the exact same manner all the time, no matter who is in charge. Such uniformity helps workers raise their operating speed, besides reducing errors and confusion.

Besides high-throughput warehouses, SOPs are required for facilities of all scales to bring clarity in place of chaos.

24. Organize Inventory with ABC Analysis

ABC classification is a proven method to intelligently organize inventory for fast picking and rapid order fulfillment.

Class A goods are fast-moving goods that typically constitute 20% of your inventory volume while providing most of your revenue. These should be placed closer to your workers to reduce average travel time. The result is faster retrieval and processing.

Class C goods are slow-moving goods that typically constitute most of your inventory volume while providing just a small percentage of your total sales. These goods may be stored deeper inside without causing a significant increase in average travel time for your workers. That’s because they have less demand.

Class B goods are somewhere between Class A and Class C goods.

Hence, ABC classification is a smart way to expedite order fulfillment and raise warehouse efficiency.

Implementing this proven tactic is much easier with a feature-rich inventory management system that supports ABC classification out of the box.

25. Use Dynamic Slotting

Dynamic slotting changes the storage location for goods that see sudden spikes in demand, for example, due to seasonal trends. For such goods, you can keep them at a more accessible point. Hence, the most accessible spots can be assigned dynamically for goods that suddenly start selling more.

This method is great for keeping up warehouse productivity during high-demand seasons, promotions, and so on.

26. Automate Returns Management

Returns processing is inevitable. And that is a problem because it is a major productivity killer. Hence, you need to automate returns management so that reverse logistics does not get in the way of your daily operations.

An all-in-one inventory management system will help you automate this time-consuming process so you can save time, money, and effort.

The system will also be able to do it accurately and quickly. This matters since fast and precise returns management is crucial for maintaining customer satisfaction and brand prestige. With automated returns management, you won’t face negative reviews online that drive away customers.

Returns management can be the difference between success and failure. Great ecommerce brands provide consistently high service quality with robust ecommerce management systems that keep customers satisfied.

27. Run Simulating Software for Testing New Workflows

Investing in a major change to your warehouse floor is a significant risk since, without testing, you can’t be certain that this change will provide the intended results.

You can remove the uncertainty with simulation software by testing proposed changes before implementing them.

There is plenty you can test, like new conveyor systems, different racking configurations, re-slotting strategies, and more. You can thus innovate with high confidence.

28. Invest in Training

Since your workers will remain your number one resource, it is necessary to train them well. Upskilling and cross-training your staff is extremely useful since it makes them far more versatile. Such staff are better positioned to fill in the gaps when there are sudden spikes in demand and worker shortages.

Investing in employees also boosts morale and motivation, thereby improving staff retention rates. You can thus retain high-performance professionals for longer with this strategy.

29. Schedule Regular Preventive Maintenance

Keep your warehouse equipment in good shape via scheduled preventive maintenance. Doing so will prevent sudden breakdowns that cause disruptions to your workflow.

Moreover, it is necessary for safety compliance. Plus, it increases the lifespan of your costly assets (forklifts, conveyers, and so on), thereby boosting your return on investment.

As the old saying goes: a stitch in time saves nine. Hence, preventive maintenance will save costs in the long term.

30. Streamline Inbound and Outbound Logistics

Receiving is the first step of your warehouse workflow. Whether it is your own fleet or a 3PL partner, strong coordination and management are necessary to ensure the timely arrival of your purchased goods. Logistics platforms like WareGo have built-in support for inbound/outbound fleet management and 3PL coordination.

Delivery scheduling, route optimization, and delivery tracking can all improve outbound and inbound operations. For example, well-spaced deliveries can reduce congestion at receiving stations.

Is WareGo the right fit for your business? Find out with a 100% FREE trial.

Start My FREE Trial!31. Incorporate 5S into Your Warehouse

The 5S method is known to bring good results for those who adopt it. 5S stands for (1) sort, (2) set, (3) shine, (4) standardize, (5) sustain. The 5S approach replaces clutter with clarity and eliminates chaos by creating order. You can transform your workspace into a clean, safe, and productive environment with this technique.

The 5S method emphasizes sorting out the needless stuff to create order. What remains must be organized logically. Regular cleaning is also vital. This ordered approach must then be standardized and sustained to bring lasting benefits.

By using 5S, warehouses report reduced errors, delays, and accidents.

32. Pay Attention to the Environment

Giving due regard to the environment lets you build brand prestige, nurture a strong rapport with your audience, and help you stand out as an ethical entity.

It can even result in cost savings. For example, going paperless can reduce expenses and even boost productivity.

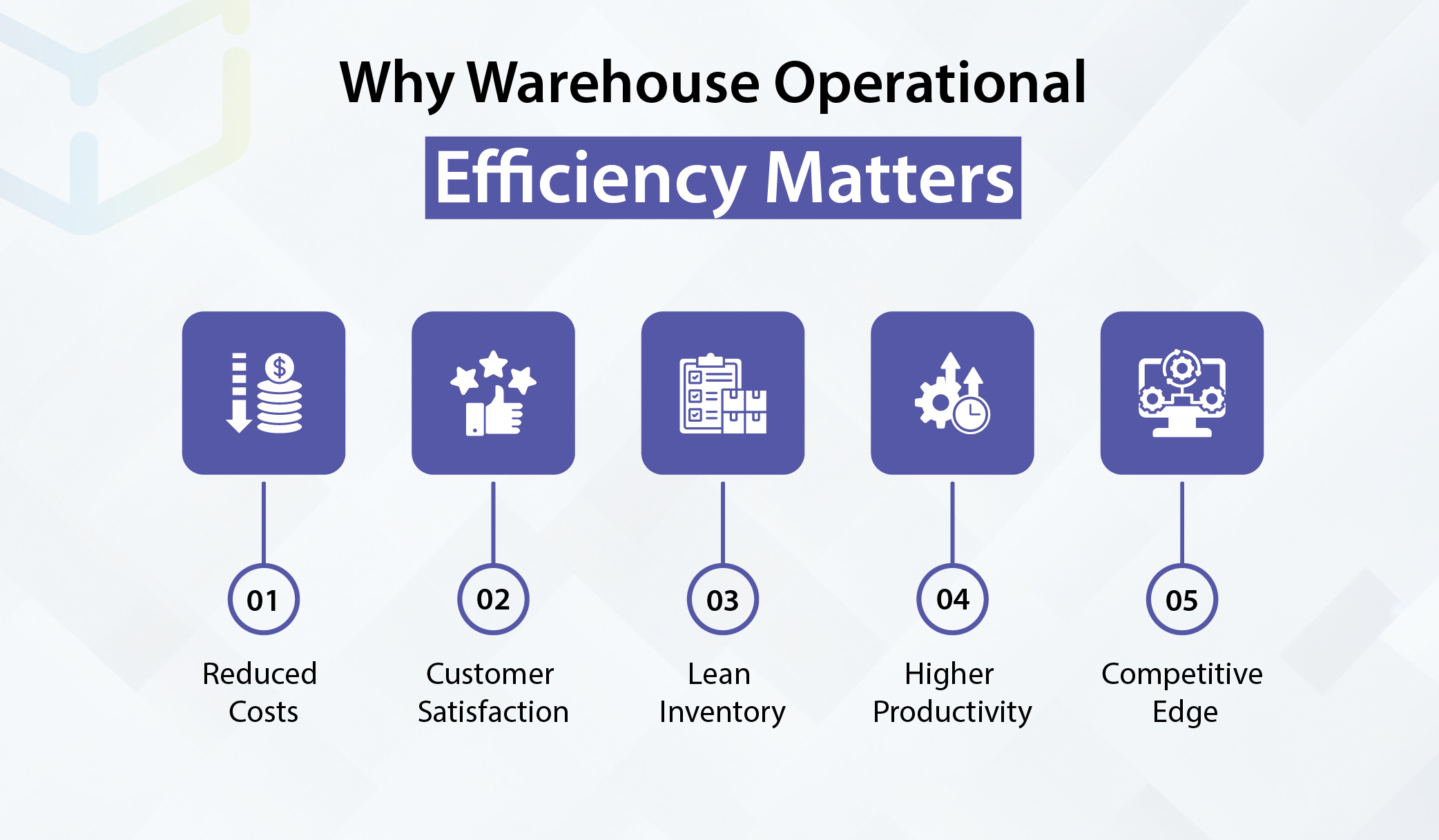

Why Warehouse Operational Efficiency Matters

High warehouse operational efficiency means higher agility, precision, and profits. Here are the reasons why.

Reduced Costs: Reducing the costs of inventory management, labor, and warehouse storage improves profit margins and cash flow.

Customer Satisfaction: Timely order fulfillment and high precision mean that customers will continue ordering from you instead of your rivals.

Lean Inventory: Efficient warehouses maintain just the right amount of inventory that reduces stockouts, overstocking, and subsequent high costs.

Higher Productivity: Your workers can achieve more with less effort courtesy of smart inventory placement, automation, RFIS/barcode scanning support, and other smart WMS features.

Competitive Edge: With reliable and rapid order fulfillment, you become the go-to choice for savvy customers.

Risk Reduction: Efficient warehouses are better poised to minimize the negative effects of disruptions, like changing consumer demand.

Warehouse Efficiency Metrics

Calculating and tracking certain warehouse efficiency metrics keeps you informed about performance levels in your warehouse. Here they are.

1. Inventory Accuracy Rate

This figure gives you the accuracy of inventory counts. Improving this metric means fewer costly errors, stockouts, and delays.

Inventory Accuracy Rate = (Quantity of accurate inventory items / Total items in inventory) x 100

2. Order Picking Accuracy

As implied, Order Picking Accuracy gives you the percentage of accurately fulfilled orders. The figure should be close to 100% for high customer satisfaction – order management software helps you hit this benchmark.

Order Picking Accuracy = (Number of orders accurately fulfilled / Total fulfilled orders) x 100

3. Perfect Order Rate

You might wonder: how is the perfect order rate different from the order picking accuracy explained above?

The answer is simple. Perfect order rate goes beyond accurately picked orders. It includes timely shipping and perfect delivery.

For example, with late shipments or goods damaged in transit, you can have full order picking accuracy but a low perfect order rate.

Hence, a high perfect order rate is an indication of operational excellence. It improves customer experience, reduces costs, and boosts profits.

Perfect Order Rate = (Number of perfect orders / Total orders shipped) x 100

4. Order Cycle Time

Order Cycle Time gives you the time frame required for completing an order. It encompasses all stages of order fulfillment – picking, packing, processing, and order shipment. Tracking this figure informs you about any bottlenecks that arise.

Order Cycle Time = (Delivery date – Order date) / Total orders shipped

5. Inbound Throughput

Inbound throughput gives you the effectiveness of inbound operations. It covers goods receiving, unloading, inspections, quality checks, inventory counts, and other workflows for receiving inbound goods. Tracking this figure ensures that your warehouse receives goods on time to avoid stockouts and order fulfillment delays.

Inbound Throughput = (Quantity of received Items / Time taken to receive items)

Ways to Improve Warehouse Efficiency

The numbers mentioned above are basically benchmarks. As with all benchmarks, you will need to establish reasonable baselines for fair comparison.

For this, internal audits are necessary for important processes like inventory management, picking, packing, receiving, and so on. You must gather data on employee productivity, order processing times, inventory levels, and more to identify the bottleneck hampering your benchmarks. This will let you find ways to improve warehouse efficiency.

Whatever improvement strategy you implement for your warehouse, you can gauge its effects by means of the aforementioned benchmarks and others besides.

A modern small warehouse management solution gives you a wealth of benchmarks to accurately determine warehouse efficiency and take it to the next level.

Warehouse Management Efficiency Simplified

You can implement the pro-tips provided to significantly improve warehouse efficiency management.

However, one thing is for sure.

Without a great warehouse management solution at the helm, you can’t achieve the high level of operational excellence you truly deserve.

The field-tested warehouse solution WareGo empowers you to implement improvements easily and accurately track their effects.

Efficiency boosting measures mentioned above, like automation, advanced inventory management, ABC classification, serialization, slotting, and many more, are supported out of the box in WareGo.

That’s because our software is engineered with one goal in mind – to transform your warehouse into a fulfillment powerhouse.

Our friendly experts will be delighted to explain how WareGo can bring real value your business.

Start My FREE Consultation!FAQs

What is warehouse efficiency?

Warehouse efficiency indicates operational performance for your warehouse. High warehouse efficiency means your warehouse staff can achieve more with less work. This leads to greater speed, precision, and ease in customer order fulfillment. You can thus save costs, boost profits, and grow your customer base.

How to make a warehouse efficient?

The best way to do so is by using a top-tier warehouse management system like WareGo, since it hosts a wealth of smart features designed to boost warehouse efficiency. These include ABC classification, serialization, slotting, precise AI forecasts, and much more. WareGo is highly affordable, and it yields tangible returns that pay for itself.

How to measure warehouse efficiency?

Several KPIs (key performance indicators) are used to determine warehouse efficiency. Here are the main types.

Speed – order cycle time, picks per hour, and inventory turnover. They indicate operational velocity.

Precision – order picking accuracy, inventory accuracy, perfect order rate. These determine operational accuracy.

Space and Cost – space utilization, cost per order. These show how well the limited warehouse space is being utilized.

The trusted warehouse solution WareGo enables easy calculation and tracking for all KPIs.

What are the four pillars of a warehouse?

These are the four pillars of a high-performance warehouse.

Labor: A highly productive, skilled, and professional staff means faster and more accurate order fulfillment.

Space: Optimal utilization of warehouse space is necessary to keep costs down and to facilitate fast inventory processing.

Equipment: forklifts, handheld scanners (barcode or RFID), and mobile devices are vital for streamlined operations.

Information: real-time holistic visibility across the busy warehouse space is vital for effective management. Automation is key for fast, accurate, and smart operations. All this and more are possible with a great warehouse management solution like WareGo.