The exponential growth of ecommerce in recent years means that order fulfillment is now more important than ever. So, having the right strategy for order processing in supply chain management is vital for meeting growing demand and customer expectations. This could be achieved with a supply chain management software as it streamlines both order processing and the supply chain. The workflow for order processing should be flexible enough to keep up with growing online demand. All steps in fulfillment processing, from receiving orders to shipping packages, need to be optimized to enhance customer loyalty and brand image. This can be achieved via an inventory management software.

In this blog, we will go through the whole procedure of order processing, how it works and its’ importance in supply chain management.

Next-gen inventory software optimizes inventory for efficient order processing.

Let’s Talk!Table of Contents

Example of Order Processing

Here is an order processing example to understand what is involved in this process.

- Suppose a customer buys a laptop online.

- An Omnichannel software immediately forwards the order to the right warehouse for fulfillment and updates stock data.

- A worker then picks the right SKU, completing the process with barcode scanning to update the order status.

- The inventory software has barcode scanning support to update the order status by means of quick barcode scans instead of manual data entry.

- The item is packed securely and shipped off to the waiting customer.

- Robust inventory software keeps the customer informed about shipping status.

Order Processing Software

Although order processing can be done with spreadsheets, a better solution is needed for a growing company to handle increasing operational complexity. As demand volume increases, fulfilling orders accurately on time becomes increasingly challenging. This situation represents a major risk since fulfillment mistakes and delays can drive away demanding customers.

This is where the order processing software comes in. The system can automate key processes to minimize human errors and delays, greatly improving productivity. By improving fulfillment performance, the software plays a key role in maintaining high customer satisfaction.

The software performs several critical tasks for efficient fulfillment, like organizing order data, tracking inventory, and maintaining safe stock levels. Hence, the software has a big role in maintaining strong customer satisfaction, even as demand grows.

Consistently good customer loyalty and brand image can attract new customers. Hence, by improving these key metrics, the system becomes a catalyst for growth. What’s more, the system integrates inventory, warehouse, and order data with other business tools like your ERP, CRM, and accounts software. Hence, the order processing software automatically updates your business tools without manual data entry. Your staff saves time, productivity rises, and human errors go down.

Our order fulfillment solution works wonders for customer satisfaction.

Start FREE Trial!Importance of Order Processing in Supply Chain Management

The importance of order processing in supply chain management cannot be overemphasized. It streamlines customer orders for accurate and timely completion. Normally, order processing is carried out in warehouses or distribution centers where workers carry out picking, packing, sorting, and other such fulfillment operations. Modern warehouse software simplifies warehouse, order, and inventory management.

To Summarize:

- Order processing is crucial for maintaining high customer satisfaction.

- Order processing becomes increasingly challenging as demand grows.

- Order processing software is the answer to growing demand since it has the necessary tools for increasing fulfillment performance.

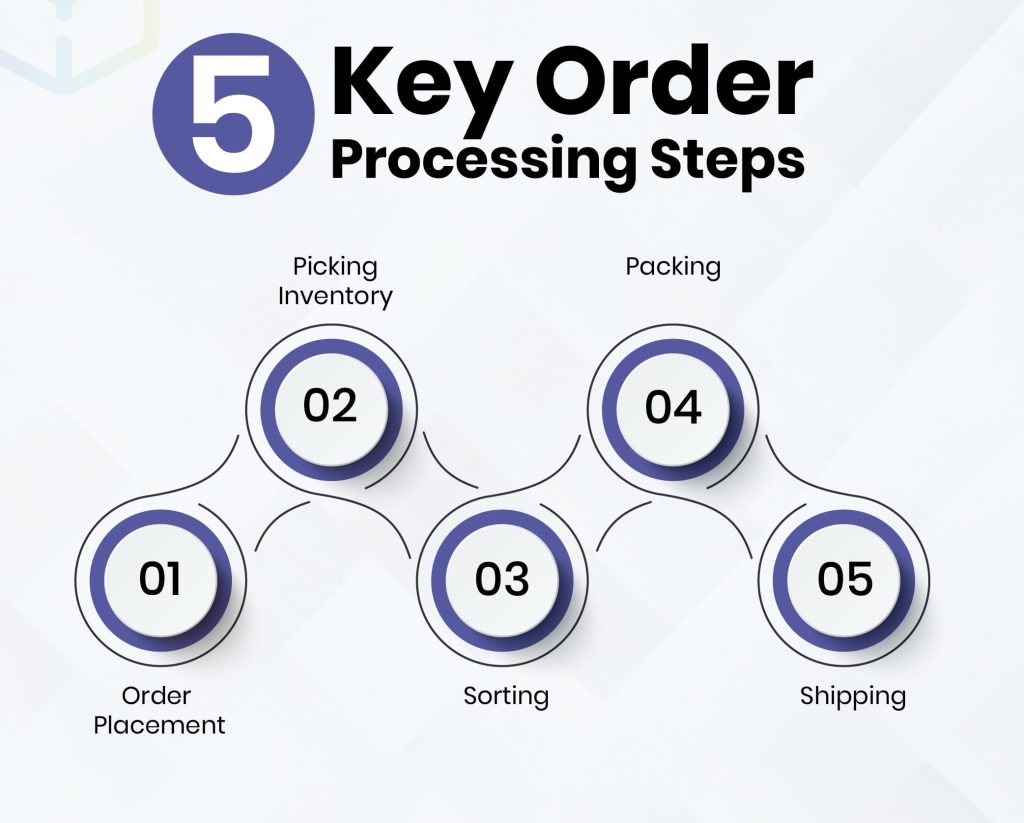

5 Key Order Processing Steps

Here is a simple breakdown of some of the key steps involved in order processing:

1. Order Placement

When a business receives an order from a customer, several important details are sent to the order management system, like item type, quantity, shipping address, customer name, and so on. If the organization has multiple warehouses or fulfillment centers, the system selects the one closest to the customer. The major advantage here is that shipment costs and time frames go down.

The system can handle complex fulfillment tasks as well. For example, if an order requires different items and some are unavailable at the warehouse closest to the customer, the system will request them from other warehouses. This is much faster than waiting for the closest warehouse to restock.

2. Picking Inventory

While it sounds easy, item picking is not all that simple, especially with high demand. The picking process needs to be automated and streamlined for quick completion and accuracy. RFID/barcode scanning support in an order management system can greatly speed up picking, since customers can update the order status with just a scan instead of tedious data entry. Human errors also go down as a result, and picking accuracy increases, leading to higher customer satisfaction.

Different inventory picking strategies can be used to speed up the picking rate.

- Batch: Each worker processes a group of orders in one go.

- Wave: Workers pick similar items together.

- Zone: Workers are assigned to specific warehouse areas, processing orders whose items are in their area.

High-throughput fulfillment centers often carry out picking with robots and specialized picking hardware.

3. Sorting

Once picked, items are grouped by their destinations. Items are also checked to ensure they are in good condition. Grouping items by destination improves shipment times and enhances the customer experience.

4. Packing

Following picking and sorting, items must be packed securely to prevent damage in transit. Other processes are also involved, like weighing each package and labelling them correctly for shipping. Whether you go for custom or generic packaging, it must be cost-effective.

5. Shipping

Packaged items are shipped to relevant destinations. With long shipping distances, shipped items are often gathered in a fulfillment center before their final journey to the customer’s address. Doing so boosts efficiency and cost savings. A system with shipment tracking improves the brand experience by showing the shipping status to waiting customers.

The leading warehouse software takes operations to the next level.

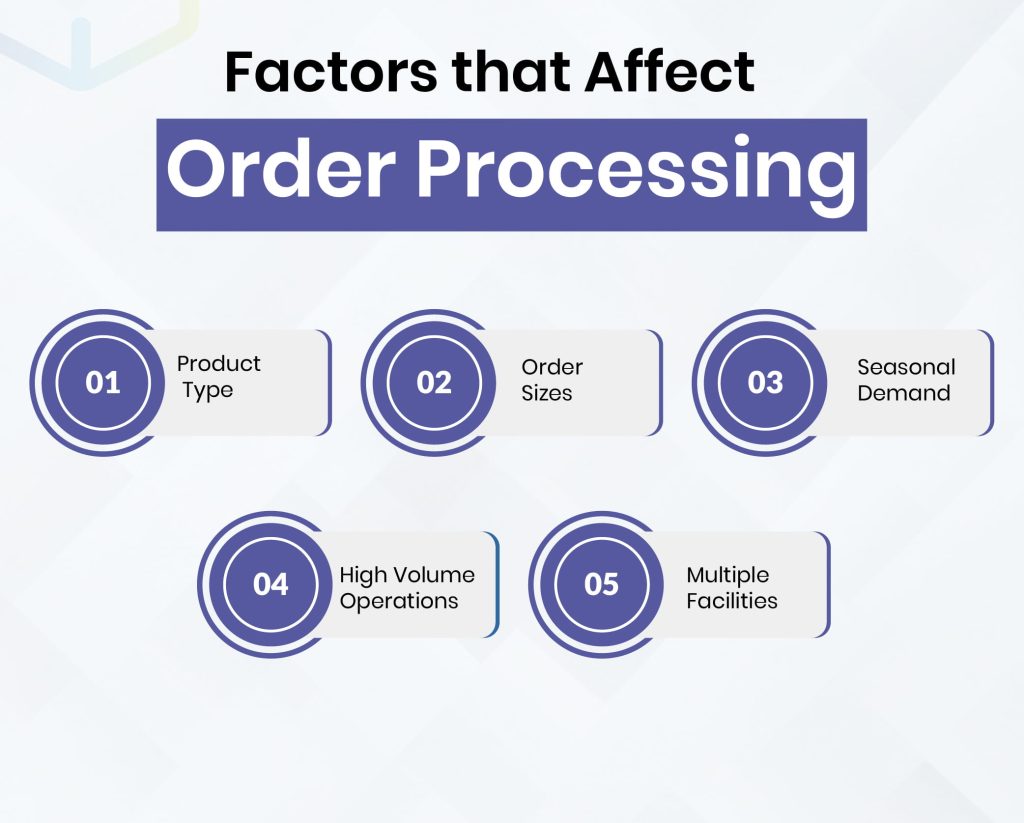

Book FREE Demo!Factors that Affect Order Processing

Slight differences may exist for order processing workflows based on the business model. Below are the following factors that strongly influence order processing.

- Product Type: Perishable goods (like foods and beverages) require temperature control and FEFO (First Expired, First Out) inventory management. Nonperishable items like furniture don’t need any of this.

- Order Sizes: Bulk orders need different handling compared to small orders. Bulk orders require freight services for shipment. Smaller orders can often be shipped via the postal service.

- Seasonal Demand: Items with highly seasonal demand require advanced forecasting tools to prevent overstocking and stockouts, even as demand fluctuates.

- High Volume Operations: High-throughput warehouses and fulfillment centers need robots, conveyors, and specialized picking hardware for quick, precise fulfillment.

- Multiple Facilities: Advanced supply chain management is needed for efficiently running multiple inventory processing facilities spread across distant locations.

The proven inventory software simplifies inventory management.

Book Expert Consultation!Types of Order Processing in Supply Chain Management

The main purpose of efficient order processing is to improve order fulfillment speed and accuracy. For this purpose, order processing software captures and organizes order information within a centralized database. A single source of truth simplifies access to real-time order data. For instance, shipping staff can access order information at any time they like to find out how many orders are ready for shipping.

There are two main types of order processing in supply chain management.

- Spreadsheets: Many organizations, from small businesses to large enterprises, still rely heavily on spreadsheets for order, supply chain, and inventory management. Trouble is, spreadsheets are not designed to scale and are not ideal for real-time updates. Hence, spreadsheets quickly become chaotic as demand grows. But they are still in use since they are simple and familiar.

- Order Management Software: Specialized solutions for inventory and order processing are far more efficient than traditional spreadsheets. Automation and management features speed up processes, reduce effort, and minimize human errors. The system is designed to grow with your business, making it the ideal tool for dealing with demand spikes.

Automate manual tasks, boost productivity with the premier inventory software

Let’s Talk!Advantages of Order Management Software

Order management software can greatly accelerate fulfillment speed and precision, making it a proven means of improved brand image and customer loyalty.

The software improves picking, packing, and sorting efficiency through real-time tracking and comprehensive management. Built-in validation rules reduce fulfillment errors by ensuring that order fulfillment details fully match customer orders.

Quick, precise shipments enhance brand experience and drive loyalty, allowing the business to attract more customers. Hence, order management software can serve as a robust foundation for business growth.

Disadvantages of Order Management Software

Despite their numerous advantages, order management systems also have certain drawbacks that can’t be ignored.

An enterprise order management software is complex and costly. The personnel using the software may require training before they become productive and extra costs such as on-premise licensing fees, deployment costs, maintenance payments, and consultation costs can easily run into tens of thousands of dollars.

This is why WareGo is a refreshing change since it offers the right mix of easy-to-use enterprise features without costing you a fortune and has a user-friendly interface so it is easy to navigate around the software.

Proven Tips for Supply Chain Order Management

Take a look at some of the proven tips for supply chain order management.

Track All Processes

Operations are much more efficient with real-time tracking for all processes. Close monitoring allows for proactive instead of reactive management. That is, hidden problems can be identified and resolved in time before they create serious disruptions. Instant reports and detailed analytics also become possible – these supply valuable insights for growth.

Accurate Forecasts

AI-powered forecasts improve forecast accuracy and simplify demand planning. Prevents overstocking. Smart algorithms can analyze large data sets to spot hidden trends that humans might miss. Smart forecasts speed up demand planning, reducing strain on your staff and preventing delays. Accurate forecasts prevent both overstocking and understocking.

Accurate Stock Data

Centralized inventory updates automatically for transactions across all sales channels. This feature greatly simplifies ecommerce inventory management and slashes human errors.

Barcode/RFID and POS terminal support automatically updates inventory without data entry. This key feature facilitates real-time order tracking and accuracy.

Standardized Processes

Standardize all processes to prevent variations that can negatively impact process efficiency. Lack of standardization is a big reason for quality problems. For all processes and workflows, you need documentation with SOPs (standard operating procedures).

KPI tracking is vital for measuring individual, team, and process efficiency. Once again, order management software offers real-time KPI monitoring.

Automatic Order Replenishment

Automatic order replenishment allows you to maintain high stock availability with less effort. Low stock levels trigger automatic purchase orders to prevent stockouts.

Timely alerts and notifications for low stock allow staff to act in time, minimizing stockout frequency.

Smart Cycle Counts

Stock taking is vital for confirming accurate stock figures. But since it halts all operations, a smarter approach is needed to minimize this major disruption.

Smart cycle counts improve inventory data accuracy by counting critical SKUs instead of counting everything, making it much faster than traditional stock taking, where everything is counted.

Intelligent Inventory Organization

ABC classification and slotting place fast-moving items within easy reach of workers. This greatly improves the item picking rate.

Reports and Analytics

These show bottlenecks, allowing you to resolve them and thus boost efficiency. They also indicate opportunities that you can exploit for growth.

However, gathering necessary data for detailed reports and advanced analytics requires a centralized system. Once again, a proven order management system is needed for this.

Multilocation Management

Supply chain management becomes easier with full visibility across all your inventory and order processing facilities.

Returns Management

Streamlines customer returns and reduces the negative impact on worker productivity. Fast and precise returns management prevents customer satisfaction from declining.

Integrations

Update inventory data on your business software tools without manual data entry. Your staff can avoid time-consuming data entry and focus on strategic matters. Human errors and delays from data entry are eliminated.

Automatic Invoicing

Saves time for your staff. Maximized invoice accuracy works well for improved customer loyalty.

WareGo’s order management software has all these features and more to streamline your order processing workflow.

Conclusion

Order processing is a key element of robust supply chain management. But for streamlined order processing at any scale, specialized software is required. WareGo’s order management system has all the tools, functions, and features for efficient order processing. The software simplifies all steps of fulfillment, no matter how complex the workflow.

So if you are struggling with processing orders at scale, then be sure to give WareGo a try by opting for a completely free trial.

See for yourself how our system accelerates your order processing workflow.

Start FREE Trial!FAQs

What is order processing in supply chain?

Order processing in supply chain refers to the different stages involved in this key process, like picking, packing, and shipping. Optimizing the entire workflow is necessary for maintaining a good brand image.

What are the five steps in processing an order?

The 5 steps of order processing are as follows.

- Order Placement: Customers issue orders, which are then forwarded to the relevant warehouses for fulfillment.

- Picking: Workers pick items mentioned in customer orders.

- Sorting: Similar items are placed together for faster processing.

- Packing: Picked items are packed securely to keep them intact during transit.

- Shipping: Packed items are shipped to customers.

What is supplier order processing?

Supplier order processing is where a third party, the supplier, handles all steps of order fulfillment for a brand and its buyers. The supplier will take care of inventory management, warehouse operations, item storage, picking, packing, sorting, shipping, and even returns.

Is order processing the same as fulfillment?

Although related, they are not the same thing. It is more accurate to say that order processing is a part of fulfillment. While order processing involves order receiving, forwarding, item picking, packing, and so on, fulfillment encompasses inventory management, warehouse management, inventory receiving, and item shipping.