his The operational processes that a business relies on are crucial for success.

The business should seek to improve all its internal processes and remove all inefficiencies so it maximizes its profit margins.

This complete guide gives you the list of 11 well-established manufacturing process improvement methodologies to maximize productivity and efficiency. Manufacturing inventory management software of the right type lets you easily implement best practices for manufacturing process improvement which will also be explained.

Our friendly experts will be happy to show how WareGo streamlines manufacturing.

Start My FREE Consultation!Table of Contents

Process Improvement in Manufacturing Explained

Process improvement in manufacturing implies optimizing all key processes to improve both productivity and efficiency. This will reduce waste, bring down costs, and thus drive up profit margins. Hence, process improvement is all about optimizing daily tasks so that your business can gain benefit from better outcomes.

You can bring about an improvement in your manufacturing processes through several different ways. For example, you can improve product quality, increase production output, and shorten delivery time frames. The methods shown in this complete guide allow your business to maximize ROI by your main processes to find room for improvement.

Why Process Improvement Manufacturing Matters

Process improvement manufacturing is crucial for production facilities that seek to take their profits, efficiency, and performance to the next level.

For an organization to successfully evolve and scale, it needs to look into its processes and find ways to improve them. By taking process improvement seriously, the organization can ensure maximal performance and the best possible outcomes. Ignoring this key responsibility, on the other hand, can lead to several undesirable outcomes like lost sales, high production costs, and losing out on lucrative opportunities that can drive growth.

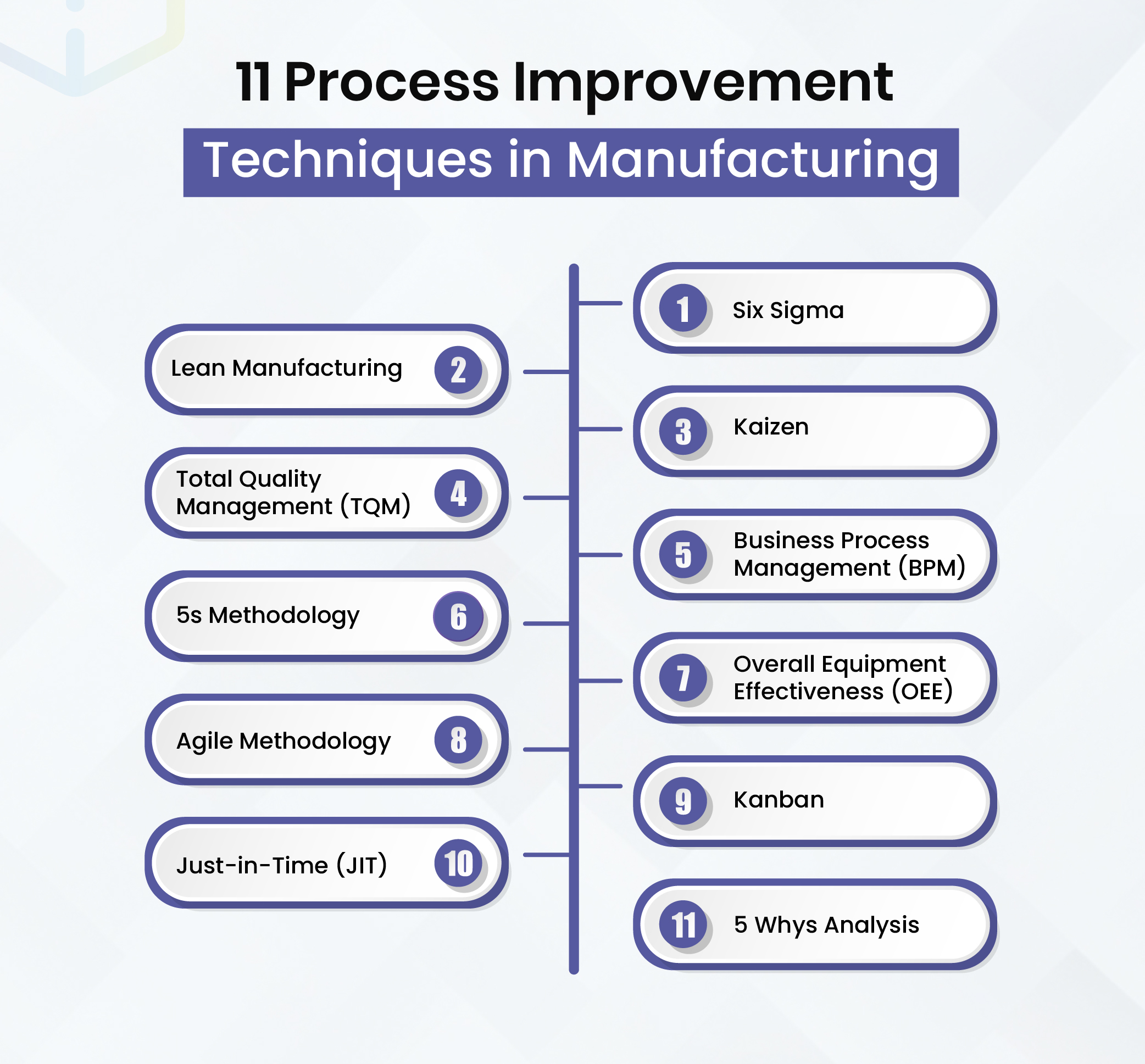

11 Process Improvement Techniques in Manufacturing

A variety of process improvement techniques in manufacturing are available which you can easily incorporate into your business. If the need arises, you can even blend the key components of these different techniques to suit your specific workflow.

Here is an explanation of the 11 proven process improvement techniques that are widely used.

1. Six Sigma

The Six Sigma method was developed back in the 1980s courtesy of a scientist working for Motorola. Statistical data is used as a tool for quality control to reduce defects. Not only does this significantly reduce variations in product quality, it also leads to a significant improvement in production processes.

The key idea in Six Sigma is that all key processes should be quantified to and then improved using statistical benchmarks.

Manufacturing companies successfully use Six Sigma to ensure high consistency in their products. This ultimately leads to a good brand reputation and higher customer satisfaction.

Six Sigma uses the following to improve existing processes.

- Defining

- Measuring

- Analyzing

- Improving

- Controlling

This can be abbreviated to DMAIC – a useful mnemonic for remembering these steps in order.

As far as new processes are concerned, the following processes are used.

- Defining

- Measuring

- Analyzing

- Designing

- Verifying

To remember these steps in the right order, you can use the mnemonic DMADV.

A closely related concept is Lean Six Sigma.

Lean Six Sigma aims to standardize all processes by minimizing the waste of resources (such as time, money, and effort). To achieve this, it relies on Lean Manufacturing and the Six Sigma approach.

Under the Lean Six Sigma method, if a resource is consumed for any process that does provide tangible benefits for the end user or customer, then this is treated as a waste and eliminated accordingly.

Our friendly professionals can show how WareGo provides tangible gains.

Chat With Us!2. Lean Manufacturing

The process is also called lean production. Lean manufacturing process improvement raises the efficiency of key processes by removing waste and using improved methods for production. The result is increased profits, higher customer satisfaction, and brand experience.

Here are the 7 different types of waste that lean manufacturing seeks to eliminate.

- Transport – materials and products transportation

- Motion – movement from one task to the next inside the warehouse of factory floor

- Waiting – time spent waiting between consecutive tasks

- Over-Processing- manufacturing processes that don’t extend tangible benefits to end users.

- Overproduction – items manufactured even though demand for them is currently lacking

- Defects – time taken to resolve errors during production

- Inventory – all items that make up your stock including raw materials, work-in-progress, and finished goods.

Lean manufacturing was pioneered by Henry Ford back in the early 1900s. Another automaker Toyota improved the lean manufacturing method during the 1940’s by implementing ‘pull’ production in place of ‘push’ production.

Some of the major advantages of lean manufacturing include higher product quality, more cost savings, and less time wasted.

3. Kaizen

Kaizen is a Japanese manufacturing philosophy also known as ‘continuous improvement’. The core premise of this widely used approach is that continuous and consistent improvement is vital for staying relevant.

The Kaizen philosophy has much in common with lean techniques. Hence, it aims to improve process productivity, product quality, and profit margins.

This method eliminates the following kinds of waste.

Muda – occurs if resources are consumed without providing real value.

Mura – a reference to unsold goods from overproduction

Muri – talks about added burden on resources like overworked employees or overused equipment.

Organizations should look into their systems and processes to identify all possible sources of waste. Inefficient processes, excess inventory, and underutilized staff could represent possible waste.

Businesses can utilize Kaizen to provide the highest quality products and services to their customers while making the best use of their resources and maximizing profit margins.

4. Total Quality Management (TQM)

Total quality management of TQM bears some similarity with Kaizen since it too is focused on providing the highest value to customers by boosting process efficiency and minimizing waste.

TQM makes extensive use of performance metrics and data to significantly overhaul systems and processes. Providing the best possible outcome for customers and end users is at the core of all TQM activities. Hence, a key question to ask before implementing any change is – what impact will this change have on customer experience?

A major difference between TQM and other quality-focused initiatives is that TQM involves the entire company from executives to factory floor workers. Hence, TQM looks beyond the manufacturing department alone and includes other departments as well to maximize benefits.

TQM shares some similarities with lean manufacturing and six sigma in that this initiative attempts to reduce inefficiencies and optimize processes while preventing defects and minimizing waste.

5. Business Process Management (BPM)

Similar to TQM and other efficiency-based initiatives, Business Process Management is involved in analyzing business processes to optimize them.

Here are the 3 kinds of business process management.

- Human-centric BPM: processes concerned with activities that only human beings are capable of performing.

- Document-centric BPM: involves documents made and utilized in the organization.

- Integration-centric BPM: adopting various applications and digital tools and integrating them.

All business entities have employees tasked with completing a series of activities to achieve specific business goals. Over the course of time, inefficiencies can creep into these activities, for example, the reliance on obsolete technologies.

As is commonly observed, outdated processes are not changed because this is what workers have perfected and are comfortable with. However, a progressive mindset is needed to excel in manufacturing. Change should be made to a process when the need arises.

BPM identifies processes that are outdated, inefficient, or wasteful. This initiative improves processes by analyzing them to optimize activities and workflows for maximum quality, output, and value.

6. 5s Methodology

The key principles of 5s were developed by Toyota as part of its lean manufacturing system. It attempts to eliminate processes that don’t provide real value, minimize waste, and boost productivity.

Here is what the 5s system entails.

- Sort – separate the tools that you need from the tools you don’t need.

- Set (in order) – identify and organize your tools for quick access and easy use.

- Shine – maintain workspaces in a clean and good condition.

- Standardise – make the aforementioned 5s steps a key part of your daily routine.

- Sustain – apply the above techniques to all other processes.

The 5s method improves operational efficiency, keeps costs under control, and prevents sudden disruptions.

See our platform live in action with a 100% FREE Demo.

Start My FREE Demo!7. Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness signifies what percentage of your planned production plan actually involves production. As you can see, OEE is a key productivity metric for the manufacturing sector.

It helps you understand how efficient your production process really is. Hence, a 100% OEE score means that your entire production schedule undergoes actual production. That is, delays, downtimes, and problems that stop production are zero.

You can measure OEE in the following ways.

- Basic: (Good Count × Ideal Cycle Time) / Planned Production Time

- Advanced: Performance x Availability x Quality

By comparing your OEE score with the industry benchmark, you can understand how your operational efficiency fares with respect to everyone else. The percentage can indicate which parts of your production process are in need of improvement.

After making changes, you can recalculate your OEE to determine if any progress has been made and if so, how much?

8. Agile Methodology

The agile approach is a well-established project management technique that is known to improve team performance.

It relies on taking feedback from each stakeholder. All possible problems and opportunities are identified to find possible areas for improvement. Seamless collaboration and open communication are at the core of this endeavor.

Here are the 4 central points of the Agile Method.

- Individuals and human interactions are prioritized over tools and processes.

- Reliable software over complete documentation

- Customer collaboration over negotiating contracts

- Responding to disruptions over following concrete plans.

Although agile methodology is primarily a project management technique, it can be used to improve processes, especially if they are concerned with project completion. Several stages are involved like evaluating, executing, and planning.

9. Kanban

Kanban gives you a visual representation of processes so you can easily analyze your workflow. This way, you can identify and eliminate bottlenecks, introduce efficiencies, and monitor process improvement.

Kanban works for “pull” production. That is, Kanban lets you plan production for fulfilling customer demand to prevent overproduction and subsequent waste. Rather than replacing systems, Kanban tries to streamline them if doing so is feasible.

Here are 6 key practices for Kanban:

- Visualize (business risks, workflow, processes)

- Minimize work-in-progress

- Streamline flow

- Outline policies in simple terms

- Create feedback loops

- Collaborate and experiment for improvements

Kanban is used across the board by major brands as part of their process improvement initiative.

10. Just-in-Time (JIT)

Although just-in-time production has several key overlaps with lean manufacturing, it is still a different process improvement initiative and should be treated as such. Pointing this out from the get-go is important since many mistakenly believe that JIT and lean manufacturing are one and the same thing.

The major principle behind JIT is that production is planned according to present customer demand. That is, overproduction, or the manufacturing in excess of this proven demand is avoided as far as possible to keep costs down. This method brings advantages like low holding costs and higher profit margins.

The Just-in-Time method eliminates key areas of waste like inefficient workflows, idle time, and overproduction.

JIT works well on its own. It can also be included with other practices such as lean manufacturing to bring greater value to customers.

11. 5 Whys Analysis

Organizations can rely on the 5 Whys Analysis method to uncover the root cause of bottlenecks, problems, and inefficiencies.

At the most basic level, this process brings together stakeholders to inquire what caused the failure.

Quite often, this question needs to be asked in several different ways to finally get to the crux of the matter. That is why it is called the 5 Whys analysis.

Persons involved with the problematic process play a key role in identifying the cause and suggesting a feasible solution for the same. A key benefit of this approach is that recurring problems are resolved by addressing the root cause so they don’t happen again.

Besides the methodologies mentioned above, you can implement process improvements just by deploying the right software for manufacturing inventory.

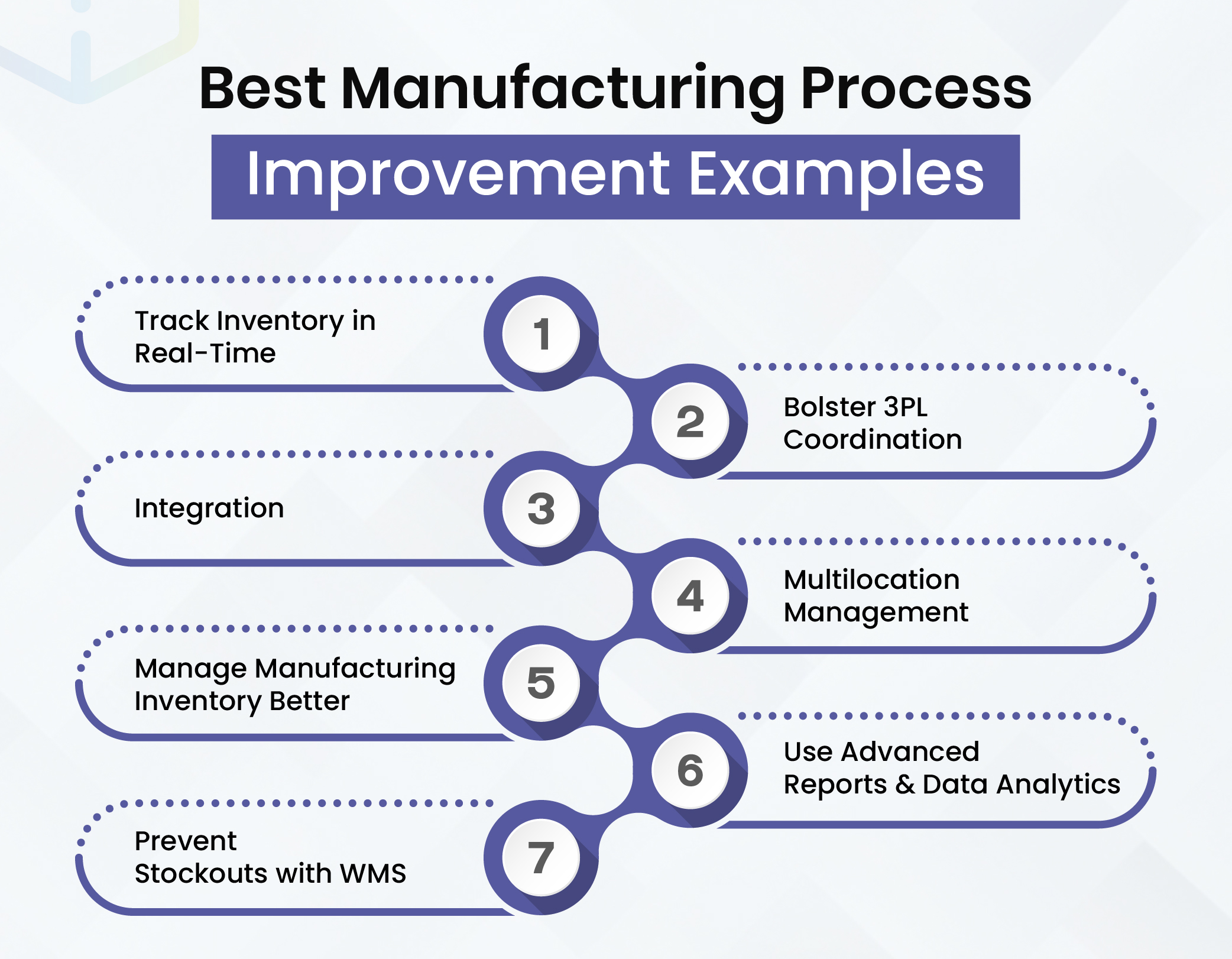

Best Manufacturing Process Improvement Examples

Some of the best manufacturing process improvement examples are those you can obtain just by deploying the right software.

Here are little-discussed but incredibly valuable benefits that you can gain almost effortlessly just by selecting comprehensive manufacturing software.

Track Inventory in Real-Time

Real-time inventory tracking allows you to follow all raw materials, work-in-progress, and finished goods easily. Thanks to accurate, updated, and complete inventory information, you can manage proactively and resolve problems before they arise. You can also track important KPIs in real-time with manufacturing inventory software like WareGo.

Take full advantage of your 100% FREE trial to see how our WMS works.

Start My FREE Trial!Bolster 3PL Coordination

Strong 3PL coordination is necessary with your supply partners for timely deliveries of raw materials and finished products. This is at the core of lean manufacturing and optimized stock levels. WareGo provides full support for 3PL coordination.

In addition, there is built-in support for crossdocking to accelerate your production processes and bring down inventory holding costs.

Full support for inbound and outbound transport operations will prove invaluable for lean manufacturing and just-in-time inventory.

Integration

Easy integration with business tools like the ERP, CRM, accounts, shipping carriers, and others is a key feature for any WMS. WareGo has over 200 integrations to sync inventory data with your business tools. This eliminates manual data entry as well as subsequent human errors and delays.

Multilocation Management

Manufacturing companies can streamline operations via a unified console that provides full visibility over multiple locations. This can simplify supply chain management for manufacturing firms that have to manage multiple facilities.

Manage Manufacturing Inventory Better

Streamline inventory storage and retrieval for fast production processes via a battle-tested warehouse platform. WareGo has everything you need to manage manufacturing inventory efficiently.

For example, ABC classification identifies fast-moving goods, placing them closer to workers for quick retrieval, while slow-moving goods can be kept deeper inside. This proven technique reduces travel time, thus speeding up operations.

Likewise, smart slotting intelligently organizes inventory in a logical pattern so that workers can’t find it easily without wasting valuable time.

Serialization lets you keep track of expensive and sophisticated items such as finished goods and components for manufacturing. This leads to high traceability, which is critical for product recalls, compliance, cost allocation, plus analysis.

Use Advanced Reports and Data Analytics

You can gain valuable insights via reports and data analytics to improve your production processes. Discovering actionable insights leads to tangible benefits like more sales, cost reduction, and higher profit margins.

Robust manufacturing inventory systems like WareGo provide on-demand reports and analytics so you can find room for improvement in your processes. Besides summarized data, you can analyze atomic data to improve your workflow.

Prevent Stockouts with WMS

WareGo WMS prevents stockouts by means of automated reordering, which replenishes stock levels automatically when inventory levels fall low. Furthermore, accurate inventory counts reduce stockouts to permit continuous production.

Fewer stockouts mean fewer disruptions for your production.

Bottom Line

Manufacturing firms can step up their game by using the frameworks and methods mentioned above. That said, deploying a manufacturing inventory software is one of the best and safest investments they can make for constant improvement to their processes.

We offer the most competitive rates for our enterprise WMS.

Check price plans!FAQs

What is process improvement in manufacturing?

Process improvement in manufacturing refers to consistent optimization of production processes so that product quality rises, costs go down, and defects are minimized. Giving due regard to process improvement is critical for capturing market share in the highly competitive manufacturing sector. Firms that make process improvement the core of their production philosophy stand to gain several advantages, such as higher profit margins, competitively priced products, and high customer satisfaction.

How can the manufacturing process be improved?

Manufacturing processes can be improved by incorporating well-established frameworks and best practices. Frameworks include the lean method, six sigma, lean six sigma, Kaizen, total quality management, and so on. Best practices include value engineering, designing products for manufacturability, data analytics, AI-powered forecasts, 3PL coordination, and so on.

What are the 7 steps of the improvement process?

The 7 steps of the improvement process are as follows.

- Select the process that needs improvement

- Make a team for improving this process

- Analyze the process

- Note down all problems with the process

- Create a strategy to improve this process

- Test this strategy

- Optimize the strategy where necessary

What are the 5 steps of process improvement?

Here are the 5 steps of process improvement.

- Define – state the project goals and what problems need a solution.

- Measure – gather all data for the current process to evaluate its performance.

- Analyze – carefully study the data to find underlying problems causing inefficiencies in the process.

- Improve – devise practical solutions to resolve all underlying problems.

- Control – create a strategy to sustain the improved process and ensure that practical solutions are implemented consistently.