Inventory accuracy is critical for many reasons. Streamlined operations are simply not possible without accurate inventory data. Without accurate inventory, maintaining customer satisfaction, speedy operations, and efficient order fulfillment is virtually impossible. Hence, maintaining high inventory accuracy should be a top priority for any business. Inventory management software is instrumental for this.

Our simple guide shows all you need to know about inventory accuracy – what it is, why it matters, how it’s measured, the challenges involved, and proven strategies for high accuracy. Let’s dive in.

Table of Contents

What Is Inventory Accuracy?

Inventory accuracy is a measure of how well your inventory records describe actual stock. So if your inventory records show 1,000 units for an SKU, your physical stock level should ideally match this, or be very close.

While it sounds simple, maintaining good stock accuracy is challenging, especially in busy warehouses. With complex operations, errors can slowly creep into inventory records without anyone knowing.

This is why inventory software is absolutely crucial as it lets you maintain accurate inventory records even in fast-moving warehouses. Such software includes real-time stock tracking, smart cycle counts, and barcode scanning to enhance inventory accuracy.

WareGo has all you need for accurate inventory and streamlined operations.

Start FREE Demo!Why Accurate Inventory Matters

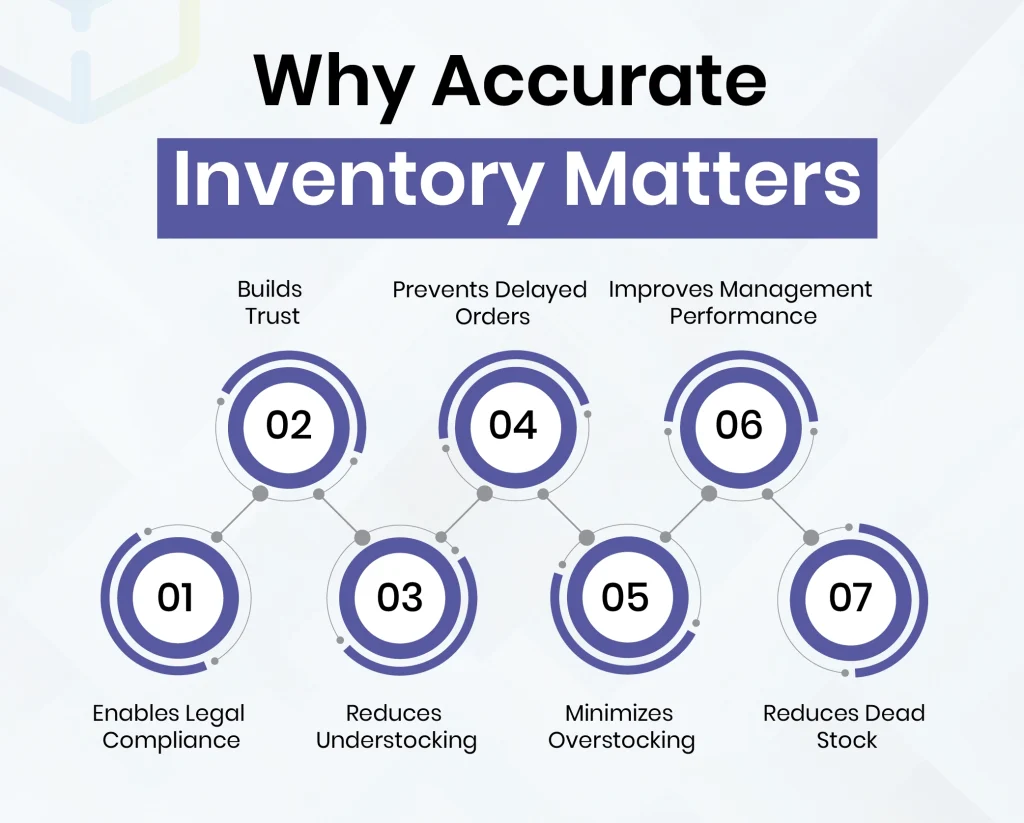

Here is why accurate inventory matters.

Enables Legal Compliance

Accurate inventory keeps you on the right side of the law. Here’s how:

Tax

Profits determine your tax amount. That said, you need accurate inventory to realistically assess your profit level.

So, without accurate inventory, you might end up paying too much or too little tax – neither is an option for you.

Reporting Compliance

The law requires precise financial reporting. As you may have guessed, this too strongly depends on accurate inventory.

Hence, you need accurate inventory to keep up with taxes and reporting regulations.

Builds Trust

As stated, stock levels strongly influence your financial reports.

Hence, going the extra mile for inventory accuracy builds confidence among stakeholders who rely on your financial reports, such as shareholders, investors, suppliers, and customers.

Reduces Understocking

With the wrong inventory figures, running out of stock is all too easy.

You then have to deal with lost sales, cancelled orders, and unhappy customers. Customer satisfaction and brand image take a big hit.

So by preventing frequent stockouts and related problems, accurate inventory improves customer satisfaction.

Prevents Delayed Orders

Stockouts are a big reason for delayed order fulfillment. Frustrated customers will look elsewhere if you can’t ship on time.

Inventory accuracy minimizes stockouts and subsequent order delays.

Minimizes Overstocking

Overstocking is just as bad as understocking, if not worse.

Excess inventory drives up holding costs, reducing profits. It also restricts cash flow by unnecessarily consuming limited funds.

Improves Management Performance

With the right inventory data at their disposal, managers can make good data-driven decisions.

For example, they can decide optimal purchase order size and frequency, streamline warehouse space, and so on, by means of reliable information.

Reduces Dead Stock

Dead stock is inventory that won’t sell. Such items consume cash, occupy space, and skyrocket holding costs. Expired goods, obsolete, and out-of-season items are examples of dead stock.

Real-time systems quickly identify slow-moving goods, minimizing dead stock.

WareGo’s smart features skyrocket inventory accuracy and simplify management.

Start FREE Trial!How to Improve Inventory Accuracy – Problems and Solutions

Wondering how to improve inventory accuracy? To do this, you need to identify the key problems that affect inventory accuracy and apply proven solutions.

Here are the details.

Data Entry Mistakes

Problem

Data entry mistakes are at the root of inventory mistakes.

Manual data entry also leads to delays, wastes valuable time, and impacts productivity.

Solution

The best way to resolve this problem is to automate manual data entry via these technologies.

- Barcode Scanning: Workers can update order status with just a barcode scan for picking, packing, shipping, and other key processes.

- POS Terminal Support: Each sale automatically updates inventory data.

- Omnichannel Support: Transactions on all sales channels automatically update centralized inventory.

- Integrations: Connect inventory software with your ERP, CRM, and accounts software to automatically update inventory in your business tools.

- Validation Rules: Halt a process if the fulfillment details don’t match customer orders.

Modern inventory management software comes with these technologies built in, making it your prime choice for automating manual processes like data entry.

Spreadsheets

Problem

Spreadsheets are still widely used for inventory management.

Despite their simplicity, spreadsheets can’t replace specialized inventory software, as they weren’t designed for complex inventory management.

For example, they don’t update in real-time and can’t support barcode scanning.

Awareness is spreading of how spreadsheets fail to scale with growing operations.

The European Spreadsheet Risks Interest Group, for example, warns against the many problems and risks posed by spreadsheet use.

Solution

Just replace outdated spreadsheets with a specialized system engineered for inventory management.

Complex Inventory

Problem

Complex inventory requires advanced inventory control to prevent errors.

This applies especially to manufacturing, where products are often made from numerous parts.

Individually picking these parts would be tedious and error-prone.

Solution

Kitting is an elegant solution to this challenge.

It bundles all necessary parts into one package so workers don’t have to pick each part separately.

This reduces both errors and delays, greatly speeding up manufacturing.

Besides manufacturing, kitting works for subscription boxes, gift sets, medical kits, and more.

Kitting software is very useful for this purpose.

Lack of Inventory Organization

Problem

Unless it is very well organized, inventory is prone to serious inaccuracies.

Solution

Slotting and serialization intelligently organize inventory, increasing inventory accuracy.

Here’s how it works.

Slotting: Arranges inventory systematically, making it easier for workers to find the right items. The risk of mispicks and errors declines.

Serialization: Assigns unique codes for each item so that workers don’t mispick similar items.

Modern inventory software provides both serialization and slotting to boost inventory accuracy.

Inefficient Inventory Counts

Problem

Counting stock is vital for high inventory accuracy.

However, counting everything is time-consuming – this is a major problem, since it stops all operations for long time frames.

So while counting everything boosts inventory accuracy, it also leads to big disruptions.

A better solution is needed – one that improves accuracy, without the disruptions.

Solution

Smart cycle counts are the answer because they target critical items instead of counting everything.

Hence, they can improve inventory accuracy without serious disruptions.

ABC classification is key here since it identifies fast-moving items that produce most of your revenue – these require more frequent counting to drive accuracy.

It also points out slow-moving items that account for a small part of your revenue – these require less frequent stock counts.

Low Visibility

Problem

If you can’t reliably monitor inventory movement, inaccuracies rise significantly.

In-stock items can get misplaced due to low visibility, leading to delays and errors.

Managers increasingly rely on guesswork, which skyrockets the risk of costly errors.

Multiple locations and disconnected data sources complicate tracking and visibility.

Solution

Real-Time Tracking: Lets you follow the entire inventory life cycle, minimizing errors.

Multilocation Management: Monitoring all locations provides high visibility over stock items.

Reports and Analytics: Identify critical inventory items that need close monitoring for higher accuracy.

Real-time inventory software with multilocation management is just what you need for high visibility over all your locations.

WareGo drives inventory precision, making management a breeze.

Let’s Talk!How to Calculate Inventory Accuracy

To find out the inventory accuracy rate, simply count each SKU and compare it with your records.

Doing this regularly shows the reliability of your inventory records. It can also quickly point out discrepancies, preventing serious problems down the road.

Here’s how to calculate inventory accuracy:

- Choose the frequency – you can count stock each week, fortnight, month, or quarter.

- Count and note actual inventory levels in your warehouse.

- Find out the variance – by how much does actual inventory vary from your records?

- Here is the formula for calculating inventory accuracy.

Inventory accuracy = (1 – (variance / recorded inventory)) x 100

- Example: Suppose the actual stock is 495 units, but the records show 500 units. The variance is 500 – 495 = 5 units.

Hence, the inventory accuracy turns out to be

(1-(5/500)) x 100 = 99%

So here, records accurately reflect 99% of the actual inventory.

Analysis: For any discrepancy, find the root cause and apply its solution. Make sure you are applying inventory management best practices.

Inventory Accuracy – How Much Is Good Enough?

Inventory accuracy from 97% to 99% is generally considered very good. However, for costly or highly regulated items, you will need close to 100% accuracy.

Automobiles, electronics, and pharmaceuticals are industries that need high inventory accuracy due to compliance reasons and costly SKUs.

Bottom Line

Inventory accuracy is at the core of efficient operations that lead to high customer satisfaction. Low inventory accuracy drives order delays and errors, which negatively impact customer experience and brand image.

Robust inventory management software has a vast suite of tools to improve inventory accuracy, like automation, integration, inventory management, and more.

WareGo packs powerful features for optimized inventory you can trust.

FREE Expert Consultation!FAQs

What is the average inventory accuracy rate?

In general, 90% inventory accuracy is considered quite good. Close to 99% inventory accuracy is highly impressive.

Why is inventory accuracy important?

Inventory accuracy is important for the following reasons:

- Legal Compliance: Accurate inventory enables precise profit calculations so you can pay the right tax amount. It also simplifies compliance for highly regulated industries.

- Reliable Reporting: Accurate inventory is crucial for reliable financial reports.

- Customer Satisfaction: Stockouts reduce with high inventory accuracy. This prevents lost sales, cancelled orders, and unhappy customers.

- Lower Costs: Minimizes overstocking, high holding costs, and cash flow problems.

- Improves Management Performance: Managers can make good data-driven decisions, identify growth opportunities, and reduce deadstock.

What is Inventory Accuracy Percentage?

Inventory Accuracy Percentage shows how closely your physical stock aligns with records. Inventory accuracy percentage is calculated as follows.

Inventory accuracy = (1 – (variance / recorded inventory)) x 100

How do you maintain inventory accuracy?

Here are the different ways to maintain high inventory accuracy:

- Automate Data Entry: Integrations, barcode scanning, POS terminal, and omnichannel support update inventory automatically, minimizing human errors.

- Avoid Spreadsheets: Replace spreadsheets with specialized software designed to scale as inventory operations grow, like inventory management software.

- Smart Cycle Counts: Count fast-moving stock frequently and slow-moving stock less frequently. This is much faster than counting everything.

- Kitting: Bundle all parts in one package so workers don’t have to pick items individually. Essential for manufacturing complex products.

- Serialization: Assigns unique codes to each item so that workers don’t mix up similar items. Minimizes errors and inaccuracies.

- Real-Time Tracking: Provides high visibility over inventory, especially when paired with multilocation management, minimizing errors and boosting accuracy.

What is a good inventory accuracy percentage?

Inventory accuracy upwards of 95% is considered very good. Close to 99% inventory accuracy is exceptional and is often important for tightly regulated industries (like pharma) and industries dealing in sophisticated items (like electronics).