Automation in manufacturing is essential for building products faster on a large scale, accelerating processes, and completing customer orders with accuracy and precision. However, given the diversity of available automation technologies, understanding the right one for your needs can be challenging. There is no doubt that manufacturing inventory management software will be at the core of any automation technology you use.

Our friendly experts can explain how WareGo can bring real value to your business.

Start My FREE Consultation!Let’s take a deep dive into different available automation options, their distinct benefits, and the trends that will define the future of this vital field.

Table of Contents

Automation in Manufacturing: Quick Overview

Automation in manufacturing refers to the use of machines and technology to perform processes with minimal or no human intervention. Thanks to the use of modern machines and cutting-edge technology, automation enhances accuracy, productivity, and efficiency across various production processes. As a result, you need less manual effort for production processes, which prevents subsequent human errors and delays.

Automation also makes your business more resilient to supply chain disruptions and labor shortages.

There are more than 4 million robots in operation around the world, as per the International Federation of Robotics. And their numbers are increasing fast, with over 30 percent year-on-year growth.

Process Automation in Manufacturing – How it Works

To successfully implement process automation in manufacturing, you need computer-controlled machines, robots, artificial intelligence, and programmable devices. Automation works best for repetitive, mundane tasks that frequently consume a lot of time and effort. Quite often, these tasks are also the most hazardous, and by automating them, you improve safety and reduce serious risks to human well-being.

Automating the most repetitive and dangerous tasks leaves your skilled labor force free to pursue other tasks that require more human skill and creativity.

Automated systems have many clear benefits. However, you should factor in the revenue and cost savings forecast for this equipment to ensure you will get the desired return on investment.

5 Benefits of Automation in Manufacturing

Although automation calls for heavy investment, it pays for itself by increasing throughput, enhancing accuracy, and making your work a whole lot easier.

Here are five main benefits of automation in manufacturing:

Higher Efficiency

Automation should handle your key processes since it vastly increases efficiency far beyond what is possible through human effort alone. Humans can’t match machines when it comes to work output.

Robots, machines, and automated equipment never get tired, don’t take time off, or even require pay for that matter. Hence, it’s not hard to see why they are so highly efficient and cost-effective.

Better Quality

Besides having much higher throughput, machines are also far more consistent in terms of work quality as compared to humans. Hence, automating production leads to better quality control and lower costs as well.

When implemented correctly, automation can greatly reduce the error rate and bring it down to nearly zero. Hence, your business can offer higher-quality products to your customers at lower costs with automation.

Cost Savings

Automation helps you save a lot of money in terms of labor costs, reduced waste, and economies of scale. In general, wherever automation is introduced, you should see substantial cost savings and a massive increase in output.

Better Safety

Automating tasks often increases safety, especially if automated tasks are dangerous. For example, the use of an overhead crane for shifting heavy loads can greatly reduce back injury risk as compared to manually carrying or pushing these heavy loads.

Data Collection and Analysis

It requires more work to collect data if the process is done manually. However, with automation, this data collection can often be done automatically without manual effort. To begin with, this reduces effort and delays. Equally importantly, it also minimizes errors, which is very important for data to be useful.

To gain maximum value for your business through automation, it is vital that you understand what options are available and which one will best suit your needs. You will also need to determine the point in time at which it makes sense to introduce automation tools, hardware, and software.

Data collection and analysis become much easier with a powerful system that provides reports and analytics for valuable insights.

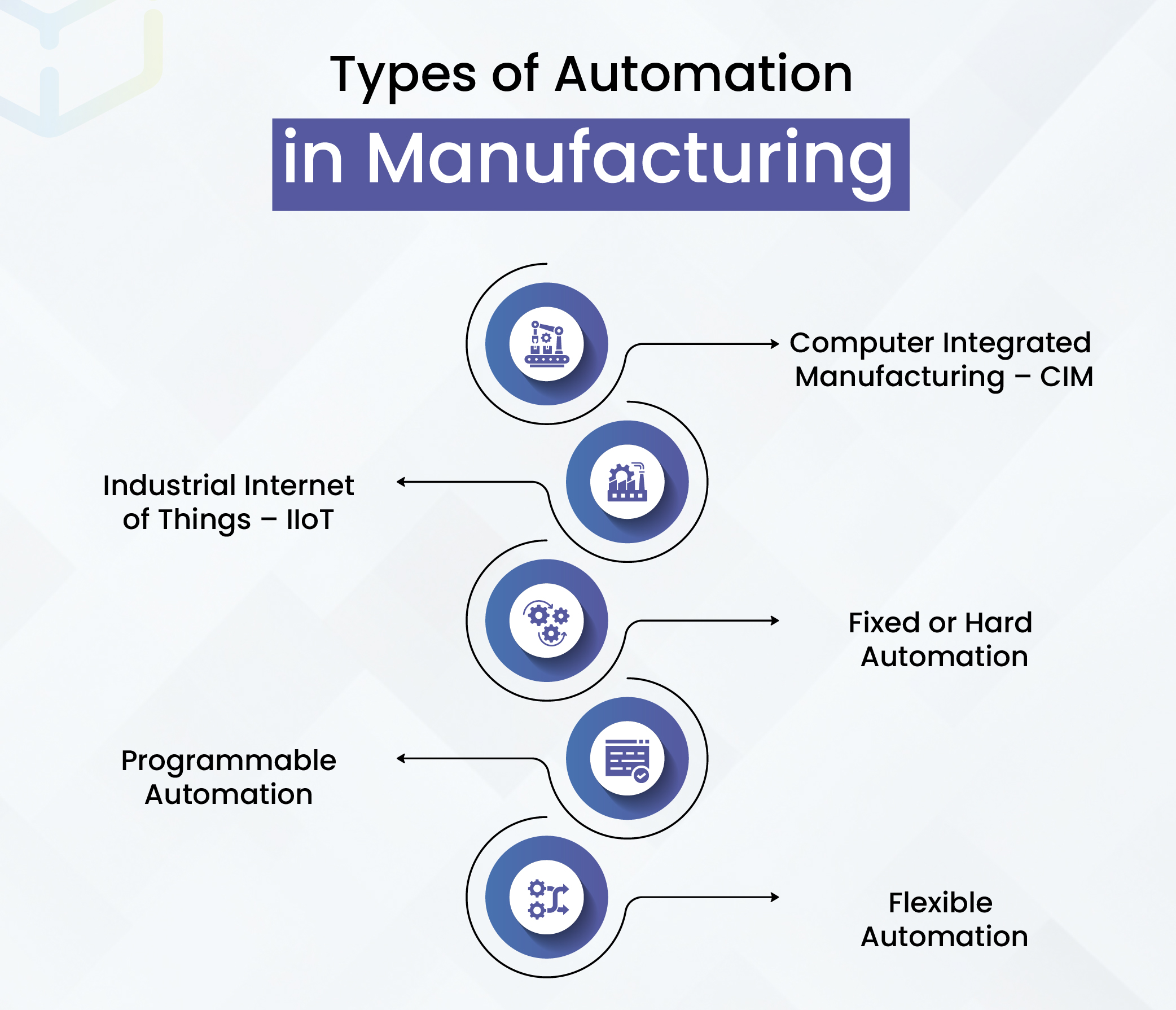

Types of Automation in Manufacturing

There are many different methods through which you can convert manual processes into fully automated functions. That said, not all automation methods may be ideal since a lot depends on the nature of the process being automated.

Here are some types of automation in manufacturing:

Computer Integrated Manufacturing (CIM)

Under CIM, the process is fully automated, as it is computer-controlled, as the name suggests. Various kinds of automation tools may come into play here, including integrations, robots, enterprise management systems, computer-aided engineering, and so on.

The CIM method manufactures products using automatic systems installed in a robotic production facility. Storage, quality control and assurance, distribution, and data management are also highly automated.

Industrial Internet of Things (IIoT)

In IIoT automation, smart devices and machines communicate with each other via sensors. These systems often rely on artificial intelligence as well. Hence, it is possible for data exchange to occur in real-time. Such a high level of control greatly improves process quality and its outcome.

“Intelligent Automation” is another process that shares many similarities with IIoT automation. Here, machine-learning algorithms are strongly integrated to enable seamless, real-time communication. This improves accuracy and outcomes.

Fixed or Hard Automation

Fixed or hard automation concerns machines that are designed to perform one specific task. They typically carry out the same repetitive action of the production line. Such machinery is programmed to execute specific tasks consistently and accurately.

Robotic automation also has certain similarities. Here, robotic arms are deployed for repetitive tasks on the production line, such as painting and packaging.

Programmable Automation

In programmable automation, a certain type of system called the Programmable Logic Controller or PLC is used to control machine operations.

With programmable automation, it is possible to produce anywhere from small amounts of units to thousands of units at a time. You can then reprogram the system to produce a new kind of product in the next batch.

Flexible Automation

As the name suggests, these systems can adapt to changes in demand by making refinements to the machines and devices involved. These systems are typically computer-controlled, in addition to being manually controlled. Hence, they have increased flexibility that enables them to adapt to changes when required.

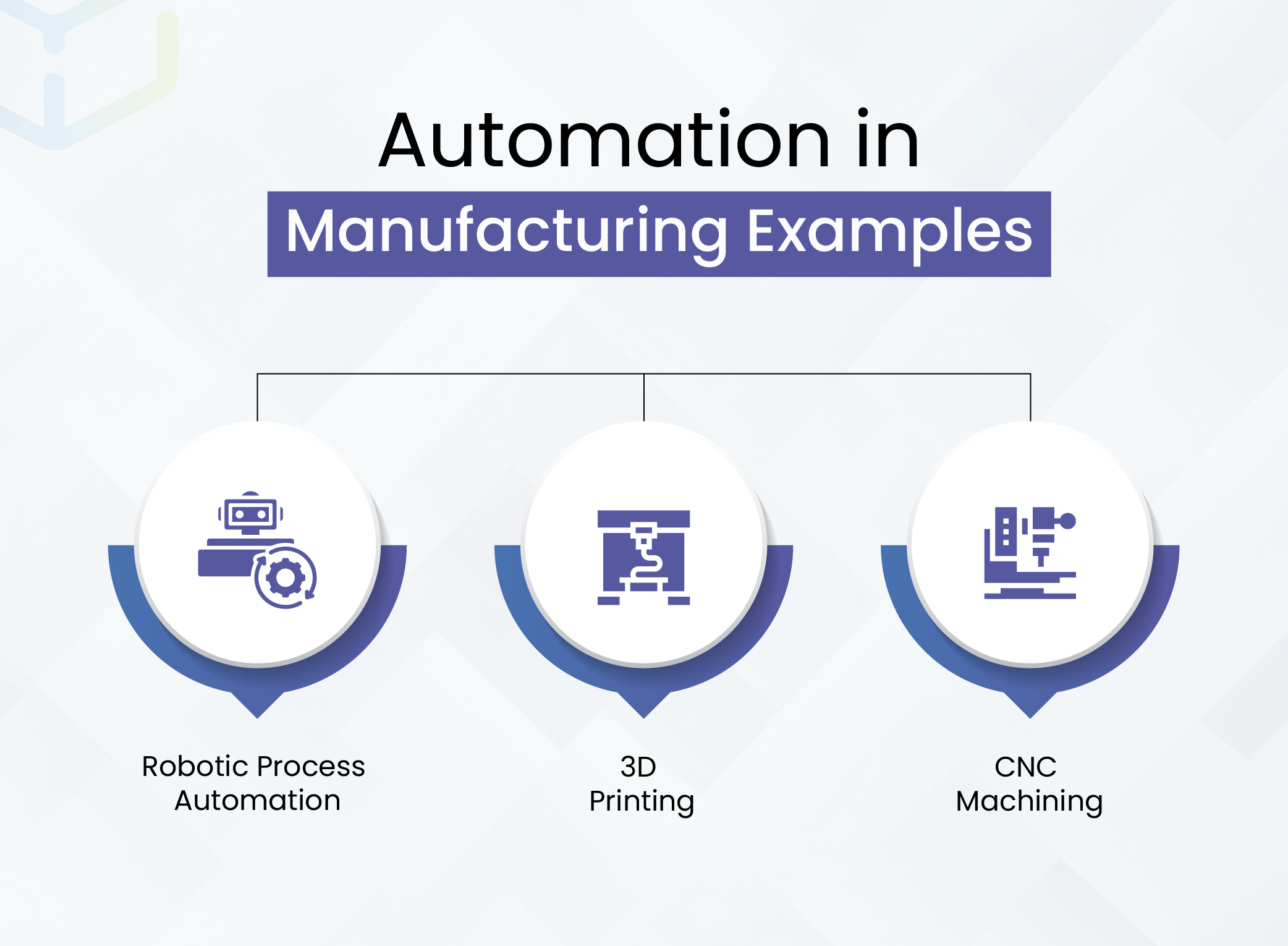

Automation in Manufacturing Examples

Manufacturing automation comes in various forms and configurations, which can accelerate processes and even transform your logistics and manufacturing operations.

Here are the different types of automation in manufacturing that are typically used across industries.

Robotic Process Automation in the Manufacturing Industry

The number of robots is increasing rapidly each year all over the world. Robots are programmed to efficiently execute repetitive tasks that are often arduous and tedious. Since they replace humans, they also reduce delays, disruptions, and errors that inevitably occur in human work. Hence, robotic process automation in the manufacturing industry is a disruptive technology that will only grow bigger with time.

Here are some manufacturing processes that robots commonly execute:

- Assembly

- Labelling

- Polishing

- Welding

- Painting

- Stacking

By introducing robotic process automation in manufacturing, you can greatly increase production output, precision, and efficiency. The costs of production will also decrease significantly.

Robots are a hot favorite with the most technologically advanced brands that are market leaders in their respective fields. For example, Tesla makes extensive use of robotic arms throughout its production line. Amazon, on the other hand, uses robots to accelerate its high-tech warehouse operations. Robots and automation are what separate these brands from others and have them stand as the best in their fields.

3D Printing

3D printing machines are ideal for printing parts of all forms, shapes, and types. These machines use a computer-based design to print parts layer by layer until the whole part is fabricated.

While traditional manufacturing processes are known to have limited flexibility, 3D printers are renowned for their high flexibility, as they can fabricate a wide range of parts. 3D printing is not just the domain of tech enthusiasts; it is in use by many leading brands such as Audi and Volkswagen.

CNC Machining

CNC machines rely on computer software to control and direct them accurately for producing complex parts of all kinds. These machines can make more intricate components than robots can normally handle.

The aerospace industry makes extensive use of CNC machining due to its high precision and throughput.

Automating Manufacturing Inventory

Inventory automation includes both software systems and equipment for controlling inventory in your warehouses and storage facilities. Advanced automation systems can provide real-time information on parts and products as they move along your supply chain.

Advantages of Inventory Automation for Manufacturing

Manufacturers can optimize inventory control to speed up production, slash errors, and increase profit margins. Automation of inventory control allows them to improve product volume while keeping costs down.

Inventory control automation allows for real-time tracking, which can greatly simplify inventory control and streamline manufacturing processes. Real-time visibility enables manufacturers to maintain the right stock levels to minimize the risk of overstocking and stockouts.

The biggest ecommerce platform in the world, Amazon, heavily relies on deep automation for managing its vast inventory. Amazon uses high-tech automation equipment such as robots to pick and shift packages throughout its massive facilities.

Amazon’s legendary ability to fulfill enormous volumes of customer orders boils down to its advanced automation, making it the biggest ecommerce entity by far.

Inventory Management Software

For automated inventory control, you need software in manufacturing automation. The cloud-based system can automate several key processes, including barcode/RFID scanning and POS terminal support, for automatic stock updates. Your stock levels remain accurate since each transaction, whether it’s the purchase of stock or the sale of finished goods, results in automatic stock updates.

Real-time monitoring and preset stock reorder points allow for automatic stock replenishment. Integrations mean that your business systems have access to real-time inventory data. This eliminates the need for manual data entry, reducing human errors and delays.

Will WareGo work for your business? Find out with a 100% FREE trial.

Start My FREE Trial!Inventory Shipment Tracking

Whether it is receiving inventory or shipping finished goods to your customers, you can follow all these key processes in real-time with powerful inventory software that comes with full 3PL support.

Thanks to this 3PL support, you can coordinate better with your 3PL partners, track their performance, automate payments to suppliers, and get the best shipping rates and terms.

Real-time shipment tracking makes it easier for you to implement just-in-time inventory, a proven methodology for minimizing inventory costs and speeding up manufacturing. Hence, with 3PL support courtesy of modern warehouse management software, you can order the right amount of goods of the right type at the right time.

A free demo will show exactly what our system can do for you.

Start My FREE Demo!Demand Forecasting and Inventory Planning

Robust order management systems have built-in AI tools that analyze your customer demand dataset to accurately forecast optimal inventory levels. Precise demand forecasts are at the root of lean manufacturing and lean inventory, which cut costs and widen profit margins.

Our price plans offer the most competitive rates

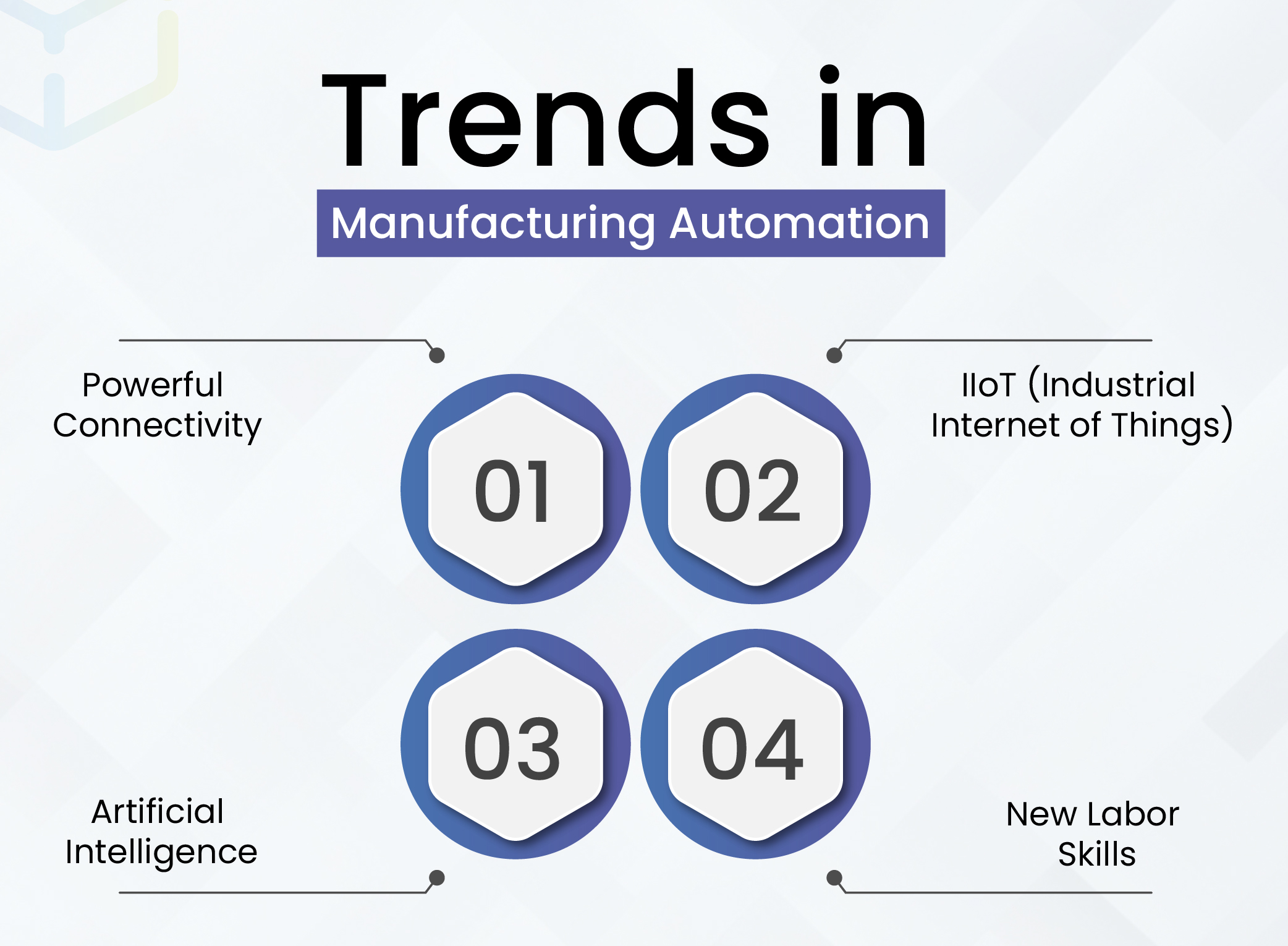

Check price plans!Trends in Manufacturing Automation

Despite looming recession fears, financial crises, and inflation, manufacturing will continue to expand.

The real winners will be those who can automate their manufacturing and business processes. This will make them more resilient to labor shortages, inflation, and recession.

Here are the key trends in manufacturing automation to look out for.

Powerful Connectivity

5G will bring strong connectivity and exceptional data transfer speeds. This will have far-reaching effects on businesses of all kinds, including manufacturing.

5G connectivity can bring immense benefits like enhanced detection of defects, improvements in assembly time, and productivity enhancements. To take advantage of these benefits, manufacturers should focus on upgrading their devices to 5G.

IIoT (Industrial Internet of Things)

The increased adoption of IIoT can bring vast benefits, as IoT-enabled sensors can communicate in real-time to streamline and automate manufacturing and inventory processes.

Since IoT relies on numerous sensors and devices communicating with each other, high bandwidth is required to facilitate seamless communication.

Artificial Intelligence

The continued rise of AI will have strong effects on the manufacturing industry that just can’t be ignored.

AI adoption must be a priority, as it can be the single greatest driver of growth and innovation. Entities that fail to adopt AI risk becoming irrelevant and uncompetitive.

AI has immense applications across all parts of your business, including manufacturing, logistics, supply chain management, inventory management, and more.

New Labor Skills

Labor will have to go beyond traditional training. Workers must have the know-how for dealing with automation equipment to fully utilize it and to prevent and resolve breakdowns quickly for minimal disruptions.

Virtual reality and augmented reality will play a key part, especially in training the labor force. These technologies can help workers upgrade their skillset.

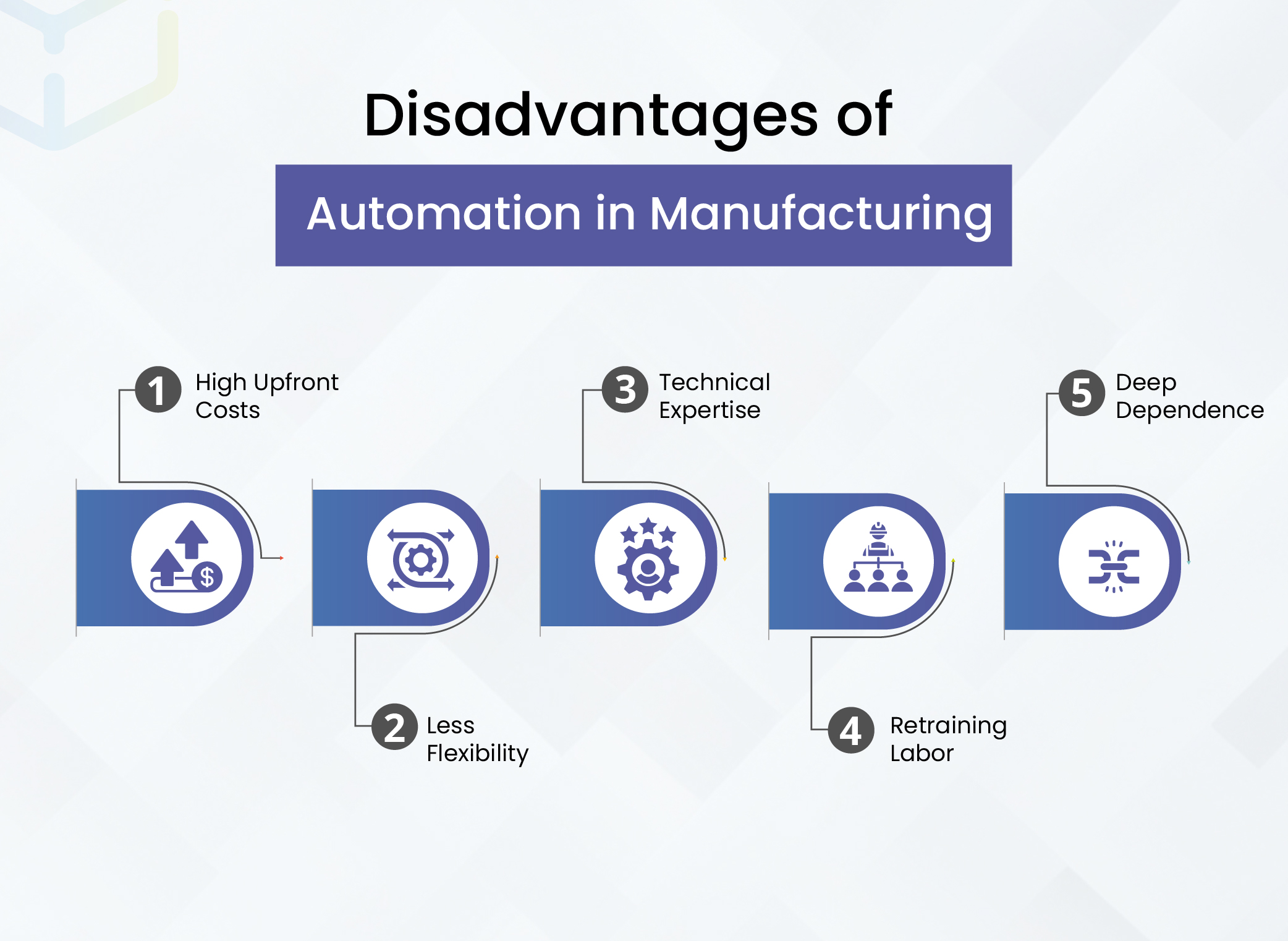

Disadvantages of Automation in Manufacturing

Although automation is paramount in manufacturing, there are serious drawbacks that need to be addressed before it can work as intended.

Here are some disadvantages of automation in manufacturing.

High Upfront Costs

Automation equipment is highly sophisticated and hence costly. Robots, autonomous vehicles, and 3D printers can have massive costs. You will need to explore available options to find the most cost-effective solution for your needs.

Less Flexibility

It can be quite hard to adapt existing tools to build new products. Extensive retooling and redesign will be needed before automation equipment is ready for manufacturing new products. This is both technically challenging and costly.

Technical Expertise

You will need experienced engineers and technicians to implement and maintain automation equipment. Finding such talent is not easy. You will need to pay these experts well to motivate them to serve you in the long term.

Retraining Labor

You will need to retrain your labor force after deploying automation equipment. They will then have the know-how for operating and maintaining this cutting-edge hardware.

Deep Dependence

Vendor lock-in is a big problem. Since there are relatively few vendors available for high-tech automation equipment, you may become highly dependent on one or two suppliers. They may charge high fees and create other problems that you may not be able to remedy, since shifting to another vendor may be too costly or not even possible if you are using niche technology.

Bottom Line

Automation is no longer just an option. It is an absolute necessity that no serious business can do without. Without automation, it is hard, if not impossible, to remain competitive. Strong automation can most certainly give you the edge over others.

That said, automation is not that easy to implement. Besides technical challenges, there are the high upfront costs you must bear.

Hence, you should check out the most affordable automation solution, WareGo. The cloud-native warehouse software provides enterprise-grade features at knockdown rates that you will be hard-pressed to find anywhere else.

It is, by far, the easiest and most cost-effective way to automate your core warehouse functions, including inventory control, and more.

So without delay, you should reach out to our friendly experts to find out all that WareGo has to offer.

Our friendly experts can help you understand how WareGo works for you.

Chat With Us!FAQs

What are the types of automation used in manufacturing?

Here are the main types of automation used in manufacturing.

- Fixed Automation

- Programmable Automation

- Soft Automation

- Integrated Automation

What are the four types of automation?

Here are the main types of automation used in manufacturing:

Fixed Automation: due to the nature of the equipment, the processes involved in fixed automation are often unchangeable and hence fixed.

Programmable Automation: Computer-controlled machinery is used for production. The software will need to be changed to make new products. This increases downtime.

Soft Automation: This is an evolution of programmable maintenance where downtime can be minimized (when switching to a different product design) by easily interchangeable parts and offline programming.

Integrated Automation: This type of automation can be considered a hybrid that combines fixed, programmable, and soft automation for maximum flexibility and throughput. This system is operated by a centralized computer system, referred to as CIM or Computer-Integrated Manufacturing.

What is L1, L2, and L3 automation?

- L1 Automation: Is concerned with sensing and manipulation. The main function is basic control logic, for example, in PLCs. The time scale is in milliseconds.

- L2 Automation: Controls and tracks processes for multiple machines in real-time. A popular use case is SCADA (Supervisory Control and Data Acquisition). Time scale is in seconds.

- L3 Automation: Manages inventory movement, quality control, scheduling, and other steps in the workflow to manufacture required products. MES, or Manufacturing Execution Systems, is one use case. Time scale is in hours or days.

What are the benefits of automated manufacturing?

The benefits of automated manufacturing include:

- Very high production rates

- Significantly low unit costs for the manufactured product

- Consistently high quality

- Better worker safety

- Improved worker productivity

- Frees up labor for more creative tasks rather than repetitive jobs

- Reduced waste