Before investing in a new business system or tool, you have to first ask – what ROI will it give me? Whether you want to invest in warehouse equipment or warehouse management software, ROI lets you make the right choice and understand the return on investment.

We will discuss everything needed to calculate the ROI for your new WMS. This will enable you to understand what value this tool is providing for your business. Whether it’s expanding your warehouse operations or improving warehouse productivity, our guide will let you know how well your WMS works for your business goals.

This guide covers the following:

- Why you should understand how to calculate WMS ROI

- How can you determine all the costs of your WMS

- What benefits does your WMS provide

- Comparing the costs and benefits for ROI evaluation

Our friendly experts can explain how WareGo helps.

Chat With Us!Table of Contents

Why the WMS ROI is So Important

A warehouse is more than just a place for handling inventory. It involves people, processes, and planning. Keeping this in mind truly matters when calculating the ROI for your WMS since you will need to factor in other benefits besides immediate monetary gains.

Besides financial benefits, the WMS can provide operational benefits and even make your warehouse a better place to work. In highly competitive labor markets, like the USA, this truly matters.

This holistic view will provide a solid foundation for assessing ROI for your WMS.

WMS ROI: Here are the Different Types of Returns

For most people, ROI is purely a monetary calculation. But that would be an oversimplification, since it misses many benefits that don’t have an obvious economic value. Hence, WMS ROI is more than just a monetary calculation.

To realistically assess what value your WMS is providing, you need to consider the following three different kinds of benefits.

- Tangible Benefits: Such benefits can be measured relatively easily. For example, reduced inventory costs, increased sales, and greater order accuracy.

- Intangible Benefits: Although they are harder to quantify, they still have a substantial impact. For instance, cycle counting automation can reduce the workload and thus improve job satisfaction. However, assigning a monetary value to this benefit is not that simple.

- Supportive Benefits: Certain key benefits may be hard to quantify in monetary terms, and they may not provide immediate financial gains, for example, improved compliance with SLAs and regulatory requirements. However, they do offer benefits in the long term.

The benefits you gain from your WMS will fall into one of these categories, and they must be included in your ROI estimation. Quantifying many of these benefits will, of course, be a challenge. However, their positive effects can be significant. For example, an all-in-one WMS can reduce mistakes, workload, and stress, thus boosting work satisfaction for both your managers and workers. This can have a positive effect on employee turnover, allowing you to retain your most talented employees on a long-term basis.

Besides just adding up monetary gains, you should also assess the ROI holistically by seeing how the WMS is helping you to solve your most significant warehouse pain points. Your software investment and other investments can start to make more sense this way.

See our cutting-edge platform live in action with a 100% FREE demo.

Start My FREE Demo!Estimating WMS Implementation Costs

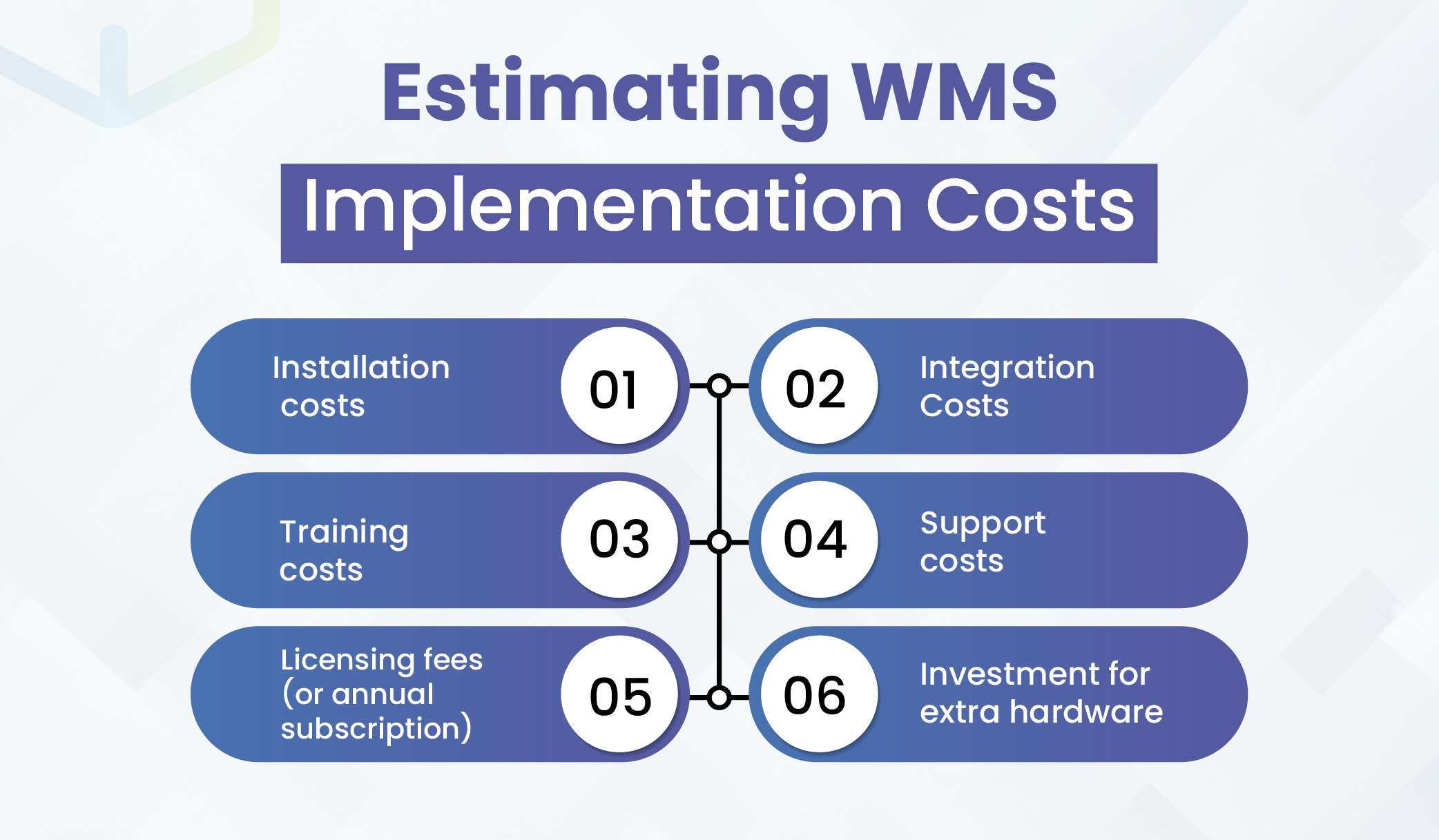

Like all enterprise software, WMS solutions also have one key challenge that you must contend with. Not all costs are provided upfront, especially implementation costs, which can be substantial. This holds true for on-premise software, but less so for cloud-based solutions.

The key advantage of cloud-based software is that it involves almost no upfront heavy investments, unlike on-premise software. This is why you should check out cloud vs on-premise inventory software so you have exactly what you need.

We also provide a complete breakdown of WMS costs you should definitely know about.

Our simple ROI calculator can give ballpark figures for WMS costs in just a minute.

The main issue with on-premises software is that WMS vendors are less forthcoming about implementation costs, as these can vary from one customer to the next. Unfortunately, these costs are substantial. You will have to provide details and take a consultation from the vendor to understand WMS implementation costs if you opt for on-premise software.

You may have to go through a lengthy RFP procedure with different vendors to understand the actual costs and returns on their software. Be sure to watch demos and take advantage of free trials before finalizing your decision.

Take care to make a complete list of all possible on-premise software costs so you are not taken aback by hidden costs. These include:

- Installation costs

- Integration Costs

- Training costs

- Support costs

- Licensing fees (or annual subscription)

- Investment for extra hardware

Back in the day, you had to make do with limited features for affordability. While this kept costs down, the limited features are insufficient for handling complex inventory.

Enterprise software, on the other hand, costs a fortune and requires significant upfront investment. Not great for cash flow.

Warego has solved this problem with highly affordable enterprise software. The vendor offers enterprise-grade warehouse features at unbelievably low rates.

Try our 100% free demo to see the WMS live in action.

Start My FREE Demo!Returns on Your WMS

Now that you have an idea of WMS costs, you can focus on returns from the software to estimate your ROI. Here is how WMS can provide returns on your investment.

Warehouse Optimization

Optimizing the warehouse floor can save you time, money, and effort. WareGo WMS lets you schedule wave and batch picking for accelerated order fulfillment. ABC classification places fast-moving goods closer to workers for quick item picking. Your labor force can become far more productive.

Inventory Management

A capable enterprise-grade WMS like WareGo streamlines your inventory for fast and precise warehouse operations. Serialization and slotting allow workers to retrieve items without searching for them. Real-time inventory updates and automatic stock replenishment prevent stockouts. AI-powered, accurate forecasts avoid overstocking.

Transport Asset Utilization

Intelligent scheduling, routing, and management for your entire fleet facilitates timely deliveries to customers. Your transport assets can achieve more with less work. All steps of inbound and outbound operations, receiving and shipping, are taken care of.

Automation

Automation significantly reduces manual work. Your staff becomes more productive since they are free to do other, more important things. For example, each transaction and inventory process automatically updates the inventory and order update status. Your workers need to just use barcode/RFID scanners without having to manually key in the data for each process.

Integrations

Warego integrates seamlessly with 200+ business systems, like ERPs, CRMs, ecommerce platforms, online marketplaces, accounts software, shipping carriers, and more. Since WareGo syncs inventory data with your business systems, there is no need for long hours of data entry. Human errors and delays are hence avoided.

Workforce Productivity

Comprehensive inventory management, RFID/barcode support, POS terminal support, automatic inventory updates, real-time inventory tracking, automated stock reordering, integrations, and several other functional WMS features in WareGo boost worker productivity.

High Customer Satisfaction

Customers, partners, and end users become more satisfied with accurate order fulfillment. Real-time inventory tracking and automated stock reordering prevent stockouts and lost sales. Customers will continue buying from you thanks to your availability and fast, precise shipments.

Reports and Analytics

Enterprise WMS serves as the single source of truth for your warehouse and inventory. WareGo provides detailed analytics and instant reports to help you optimize your warehouse operations.

Let our friendly experts explain how our WMS boosts productivity.

Chat With Us!Multichannel Inventory Management

An omnichannel sales strategy lets you target broader audiences and different markets. But that comes at the cost of more work, hectic inventory management, and higher error risks. WareGo syncs inventory across all sales channels to simplify inventory management. No more errors, stockouts, and lost sales.

You get many more benefits besides, with WareGo, like better 3PL collaboration for just-in-time inventory management, automated billing and invoicing, seamless returns management, and so much more.

How to Calculate WMS ROI

Here is how you find out the ROI on your new WMS.

Add up all costs: Include all direct as well as indirect costs, like maintenance, license fee (or monthly subscription), implementation costs, and so on.

Estimate gains: Add all gains mentioned above, assigning rough values according to reasonable estimates.

Calculate net returns: Deduct all costs from your estimated gains over a time frame of at least one year.

The end-to-end WMS will pay for itself by reducing order fulfillment error rates, speeding up operations, and saving costs. These and several other factors will give you a good return on your WMS investment.

WMS ROI Calculators

You can make use of online WMS ROI calculators to find a rough estimate in just around a minute. Using this value as a ballpark estimate, you can then find a realistic value via the method outlined above.

Final Thoughts

The WMS ROI calculation can vary according to your business model and processes. Since each warehouse is different with unique workflows, WMS benefits will likewise vary according to various factors such as order volume, inventory type, warehouse layout, and so on.

However, once you deploy a good WMS like WareGo, you will enjoy a long list of benefits that will provide a good return on your investment. Most clients report recovering WareGo investment costs in under a year.

Since the software pays for itself, it is a wise investment.

At this point, you should play it safe by relying on WareGo – the enterprise software with the complete set of features to manage your warehouse on a budget.

We offer comprehensive features at knockdown rates.

So do reach out for a 100% FREE consultation.

Talk to our friendly experts right away.

Start My FREE Consultation!FAQs

Is it a good idea to invest in a WMS?

Investing in a proven WMS is one of the best decisions you can make as a business leader. There is a limit to how much spreadsheets and legacy systems can do for your business. By opting for an enterprise WMS like WareGo, you can take your daily operations to the next level to enjoy high cost savings and improved profit margins. Higher subsequent profits represent the return on your investment. Our clients often report a 100% ROI in less than a year, so WareGo is a safe choice for your next investment.

What is the WMS trend in 2025?

Around 90% of all warehouses are now controlled by a WMS of some kind. This shows the growing importance of WMS solutions. The WMS has emerged as an essential tool for operational excellence, high productivity, and supply chain efficiency. Going without a good WMS is no longer an option. In fact, having a capable WMS is paramount if you want your business to survive and thrive under ever-increasing competition.

What WMS features should you evaluate when choosing a WMS?

WMS features that you need to carefully consider include.

- Real-time tracking – the software should be capable of providing real-time information on stock levels to allow proactive management, prevent errors, and reduce stockouts.

- Inventory Control – support for proven management techniques is needed for reasonable inventory control, like ABC classification, serialization, slotting, and so on.

- Forecasting – you can prevent overstocking and resultant high costs with the help of accurate forecasts.

- Analytics and reports – robust data analysis and reporting tools are critical for making good data-driven decisions that bring tangible benefits.

- Integrations – the WMS should sync inventory data with other systems that require this information, such as the ERP, CRM, and accounting software.

What are the 3 steps for analyzing the ROI on your WMS?

Enterprise-grade WMS solutions like WareGo often return your investment in less than a year, thanks to cost savings and more sales. You can evaluate the ROI on your WMS using the following simple steps.

Analyze Operations – take a look at all warehouse operations and daily activities, and make a complete list where everything is included.

Create KPIs – Use the most relevant KPIs to track the efficiency of all these activities in your list. If possible, assign a dollar amount (cost) for activities. WareGo lets you track several KPIs out of the box and supports accurate costing.

KPI Monitoring – track your KPIs and calculate the percentage improvement over time. For various costs, compare costs before and after. The percentage difference in price, along with improved KPIs, is the return on your WMS investment.

What factors influence WMS ROI?

The ROI of a WMS is driven by certain key factors that include:

Fewer stockouts and overstocking – stockouts result in lost sales while overstocking increases holding costs. These costs are minimized since a WMS minimizes both stockouts and overstocking.

Automated Order Fulfillment – Several manual tasks for order fulfillment can be automated with a good WMS, resulting in faster order fulfillment, for example, stock reordering.

Integration: manual data entry is eliminated, along with subsequent human errors and delays. Staff productivity goes up.

Faster Warehouse Operations – WMS support for ABC classification, serialization, slotting, and cross-docking can significantly boost warehouse operational speed.

Returns Management – streamlined returns processes mean customer returns won’t hold back your busy staff. Productivity rises.