3PL warehouse automation is central to logistics performance as it can boost operational speed, accuracy, and efficiency. Owing to the increasing demand for dependable logistics services, automation has become a key part of the 3PL strategy.

3PL warehouse management system are particularly effective.

3PL logistics is concerned with outsourcing the logistics function to a reliable specialist. Your outsourced 3PL partner can provide real value for your business via transport, order fulfillment, inventory management, and other related tasks.

3PL service providers are seeking to become more competitive by resorting to bleeding-edge technologies for high operational agility, like blockchain, augmented reality, IoT, drones, robots, and AI. While you should keep an eye on emerging technologies, you should not lose sight of well-established and proven technologies like cloud-based 3PL solutions that are known to drive efficiency, productivity, and performance for 3PL entities.

Our friendly experts can show you the best 3PL software and features for your 3PL business.

Start My FREE Consultation!Table of Contents

3pl Warehouse Automation Solutions

Both hardware and software are at the core of 3PL warehouse automation solutions. They can boost warehouse productivity by speeding daily warehouse processes like receiving, storing, picking, packing, and dispatching inventory.

Warehouse automation software, in particular, can give warehouses a powerful competitive edge with real-time inventory and shipment tracking. This provides users with accurate, updated, and complete inventory information that enables proactive rather than reactive management. That is, management can anticipate problems and challenges before they arise and thus take immediate steps to prevent them from transpiring. This is much better than responding to problems and disruptions after they take hold.

An example of this would be stockouts. Real-time inventory tracking shows in advance which stock levels are falling to critical low levels. The software will issue instant alerts and notifications informing of the same.

Download our free warehouse automation guide to help you modernize your operations!

Advanced inventory software can even carry out automatic stock replenishment according to custom rules so that stockout risk is minimized.

In addition to software solutions, sophisticated hardware can also automate inventory processes using robotic packers and pickers and other automated systems for storage and retrieval.

Inventory software and hardware automation systems can provide several benefits, like improved inventory tracking, greater fulfillment speed and accuracy, lower labor costs, and more.

Warehouse Control and Management Software

The WMS is a kind of software that lets you optimize and manage warehouse operations. The software works for all kinds of warehouse functions and inventory processes like optimizing inventory placement for fast picking, order fulfillment, real-time stock monitoring, and so on. The WMS can store a wealth of inventory, order, and operations data, which you can analyze via instant reports and detailed analytics to find insights and opportunities for improving your warehouse operations.

Integration is a key capability for any WMS since it must be able to share its vast inventory, sales, and operations data with other business systems that may need it, like ERPs, CRMs, accounts, ecommerce platforms, shipping carriers, and so on. This prevents the need for manual data entry and thus saves lots of time and effort while reducing human errors and delays.

WMS solutions can vary greatly in their scope and capabilities. Hence, you should select that WMS which can support the scale and needs of your warehouses.

Although such software can be quite different, they do share certain basic features that are common to most, like barcode/RFID scanning to track goods movement and to automatically record transactions.

The software then uses all this information to issue reports and analytics on inventory, sales, order status, and other key details.

Our friendly experts can explain in simple words how our 3PL software helps.

Chat With Us!3PL Automation Advantages

3PL automation extends a vast array of valuable benefits that can speed up warehouse operations, drive precision, and improve productivity. Here are some of these advantages.

Accurate and Fast Shipments

Since warehouses can track inventory in real-time, they can process orders faster and more accurately to achieve a high rate of on-time deliveries.

A major reason for this is that, with real-time inventory tracking, managers can see which SKU levels are becoming critically low. Hence, they can purchase stock in time to prevent stockouts and lost sales.

Robust inventory solutions provide important capabilities in this regard. For example, they issue auto alerts and notifications when stock levels fall low. Also, advanced inventory software can replenish stock by automatically generating purchase orders at specified reorder points.

By analyzing the vast data in inventory software, managers can pinpoint bottlenecks and opportunities for improving fulfillment speed and precision.

Book a free demo to see our 3PL solution live in action.

Start My FREE Demo!Enhanced 3PL Performance

3PL service providers need an exceptional level of efficiency to meet the demands of their customers. Both hardware and software automation help them in this regard.

Robots and automated equipment reduce the need for workers and execute processes much faster than humans. For instance, automatic retrieval and storage equipment can pick the right items with high speed and precision. Likewise, robotic packers and pickers are much better than human workers at picking and packing items rapidly and accurately.

Hence, 3PL service providers can greatly improve their efficiency with automation and thus enable faster shipping for their customers. Automation equipment and software can also reduce costs to widen 3PL profit margins.

Is WareGo right for your business? Find out with a 100% FREE trial.

Start My FREE Trial!Saving Space and Accelerating Logistics

Automated warehouses save more space and speed up operations using modern equipment for retrieval and storage. This equipment relies on robots and powerful algorithms to quickly retrieve and store products. Due to this, the warehouse can make better use of its limited space.

By increasing fulfillment speed and accuracy, automation lets you achieve a high rate of on-time deliveries. This greatly improves client satisfaction and enhances brand loyalty.

Since automation reduces manual effort, it can greatly reduce human errors and delays. This is vital for industries where quality control and regulatory requirements are quite stringent, for example, the food & beverage, and pharmaceutical sectors.

Check out our price plans for the most affordable rates.

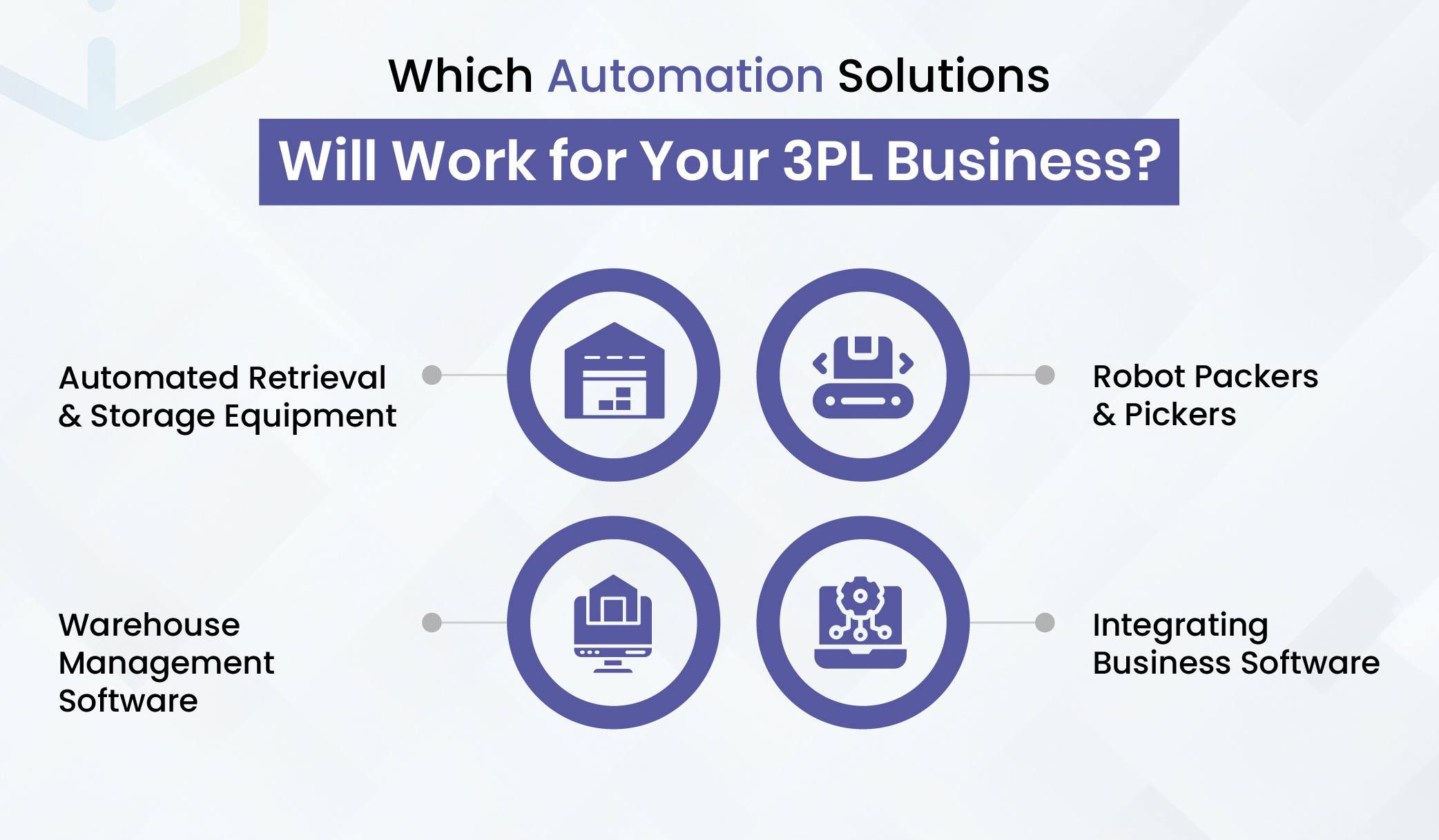

Check price plans!Which Automation Solutions Will Work for Your 3PL Business?

If you happen to be a 3PL service provider, there are several automation options that can streamline your daily workflow. Here are some:

Automated Retrieval and Storage Equipment

This equipment is built on robotics and modern algorithms designed to speed up inventory processing and order fulfillment. You can organize inventory better and make better use of your limited warehouse space.

Robot Packers and Pickers

Robot packers and pickers excel at finding, retrieving, and packing items in good time for shipping. Due to their high speed and precision, they can replace a certain level of manual work and thus boost warehouse efficiency.

However, they are not a complete replacement for humans. You still need humans at picking and packing stations to guide these robots. The robot moves to these human operators, specifying the items required for the current order. The human operator will then place the required items in the container held by the robot and scan them to confirm task fulfillment. With this arrangement, human workers can greatly reduce the distance travelled and leave the hard work (traveling long distances) to robots.

Warehouse Management Software

The warehouse management software (WMS for short) lets you track, manage, and streamline warehouse processes like inventory control and order fulfillment. Real-time tracking and full visibility via the warehouse management software are key to optimizing your supply chain for resilience and high performance. The software leverages reports and analytics to provide you with valuable insights that can save costs and drive sales.

Our friendly experts can easily explain how 3PL software streamlines your business.

Start My FREE Consultation!Integrating Business Software

Your inventory software should have powerful integration capabilities so it can automatically share its inventory, sales, and fulfillment data with other business systems you may be using, like an ERP, CRM, accounts, and other types of business software.

This capability is vital since it eliminates the need for manual data entry and thus prevents subsequent human errors and delays.

Hence, integrations are massive productivity boosters.

WareGo provides 200+ integrations out of the box. It is thus poised to provide you with the productivity boost you always wanted.

Finding the Best Solution

You can determine the best possible automation solution for your business by following the steps shown below:

1. List Your Needs

List all pain points that need to be resolved via automation. Make sure you fully understand what you want to achieve. Is it lowering costs? More sales? Or higher fulfillment accuracy? Clearly stating your desired outcomes is the first step in finding the right solution.

2. Research Potential Solutions

Research possible solutions that could achieve your desired outcomes listed above. One surefire way to achieve your goals, either wholly or partially, is by identifying the right WMS. This is the most cost-effective solution by far, with great ROI. So keep this one high on your priority list.

3. Test Your Chosen Solutions

You should also carry out a cost/benefit analysis for the solution you are testing and other potential solutions as well to find the best answer to your needs. Demos and pilot tests can demonstrate how effective the solution really is. These can also indicate technical problems that need to be resolved before your chosen solution goes fully live.

4. Select Your Solution

Once you analyze possible solutions, choose them, and test them, it is now time to deploy them for full-scale operations. At this point, you will want to train warehouse staff who will be running the system. The system should also be integrated with other business systems for automatic data exchange that eliminates manual data entry.

5. Deploy the Solution for Production

The deployment of the system is best left to the vendor who knows the system well and understands how it should be deployed for minimal disruption.

This is perhaps the riskiest phase since the system can cause serious disruptions if it malfunctions during full-scale operations.

However, cloud-based 3PL software poses minimal risk of disruption since it does not have to be deployed on-site.

The steps shown above should result in significantly more efficient warehouse operations.

Key Takeaways

3PL warehouse automation solutions can result in substantial efficiency gains for warehouse operations.

A key problem with automation is that many of these solutions, especially hardware systems, require heavy investment. Deploying them involves many technical challenges. Many of these systems are proprietary and thus present fewer options for choosing vendors.

However, all these problems are largely resolved with inventory control software – the best warehouse automation solution for several reasons.

Cloud-based inventory software solutions like WareGo don’t cost you a fortune to use. There is also no deployment problem or technical challenge with cloud native software since all of it is hosted, managed, and maintained by the vendor. Plus, there is a wide range of choices in this regard.

And cloud-native inventory software like WareGo boasts over 200 integrations that sync your 3PL inventory data with many other widely used business systems you may have, like the ERP, CRM, accounts, and others.

Real-time inventory tracking, multi-location management, automatic stock replenishment, AI-powered accurate forecasts, and several other exciting features let you step up your 3PL game.

Our friendly experts can explain in simple words how 3PL software helps.

Chat With Us!FAQs

What is 3PL in warehouse management?

3PL in warehouse management means outsourcing your warehouse function to a third-party specialist who is often referred to as a 3PL service provider or simply 3PL. The 3PL service takes care of all inventory processes, order fulfillment, and warehouse operations. Since the 3PL is a specialist with experience in the field of warehouse operations, it will do a much better job in this regard compared to nonspecialists. Plus, SMEs and enterprises can focus on growing their core business instead of coping with warehouse problems when they hire a 3PL service.

What are the three levels of warehouse automation?

The three levels of warehouse automation are:

1. Basic/Manual

Although there is some automation, most processes are still largely human-controlled. For example, barcode/RFID scanner use, forklifts driven by workers, and inventory software.

2. Semi Automated

This level of warehouse automation involves the use of advanced hardware, but there is still plenty of human oversight, for example, smart systems for retrieval and storage, robotic pickers, conveyers, AI-guided vehicles, and so on.

3. Automated

Operations can proceed with little human involvement. Automated machines and specialized hardware replace a large part of human labor.

What is the best 3PL WMS?

WareGo is the best 3PL WMS. The software has everything you need for advanced inventory management, such as ABC classification, serialization, slotting, and more. Real-time tracking and multi-location monitoring mean you can keep tabs on all warehouses and centers. Transport features like route scheduling, timing, and optimization allow you to extract maximum value from your transport fleet for faster shipping. Several key processes are automated to save time and effort, like automated stock replenishment. There are many more features that can make a 3PL more competitive.

What is 3PL warehouse automation?

3PL warehouse automation involves the use of hardware and software to speed up daily warehouse activities.

What technologies are used in 3PL warehouse automation?

Two classes of technologies are used in 3PL warehouse automation: hardware and software. Hardware options include autonomous vehicles, robot pickers, retrieval systems, storage hardware, and so on. The leading software option is the WMS for inventory control. Cloud-based platforms like WareGo are the most cost-effective solutions that require the lowest upfront investment and are easy to implement.

What challenges do 3PLs face when implementing warehouse automation?

3PLs can face significant technical challenges, especially when implementing hardware automation solutions. Plenty of testing and troubleshooting will be required, especially at the start, for automation hardware to work as intended without problems. Full vendor support is critical. This won’t come cheap and will require heavy upfront investment, as will other subsequent tasks like upgrades and maintenance.

The least challenging and simplest warehouse automation option with high ROI for 3PLs is the cloud-based WMS from trusted vendors like WareGo. The software is very easy to use. Even nonexperts can learn to use basic features on their own. Automation features, real-time tracking, multi-location management, and other such features greatly boost productivity, saving you time and effort. This solution offers a long list of benefits within budget.

What is the ROI of warehouse automation for 3PL providers?

For cloud-based WMS solutions, the ROI is substantial. The software costs you just a few hundred dollars to use each month. However, the benefits are several times this affordable amount. Workers experience a massive boost in productivity thanks to comprehensive automation, fulfillment, and inventory management features. These features also allow your workers to fulfill orders with high precision, which reduces customer returns. You avoid losing money to stockouts thanks to automatic stock replenishment. Overstocking costs are also reduced since the software lets you maintain lean inventory. Hence, cost savings, productivity, and fulfillment accuracy more than offset the few hundred dollars you pay each month for the cloud-based solution.