The Internet of Things (IoT) is a promising technology that appears poised to revolutionize warehouse management. In fact, its benefits extend beyond the warehouse to encompass all touchpoints in your supply chain. Real-time data management lies at the core of IoT in warehouse management, making it ideal for managing complex supply chains. Modern wms solutions thus have built-in support for IoT.

IoT can tackle business and warehouse operational challenges in highly innovative ways. It does so by using cutting-edge solutions like RFID tags, real-time item tracking, multi-location visibility, and more. IoT will provide even greater value for warehouse management in conjunction with rising technologies like AI, 5G, and big data analytics.

IoT-powered warehouse management utilizes deep analytics and automation for data to unlock vast opportunities.

Let’s explore how IoT for warehouse management software can benefit your supply chain, the challenges you may encounter, and how to overcome them.

Table of Contents

Revolutionizing Warehouse Management with IoT

By implementing IoT, you can accelerate inventory processing, improve warehouse efficiency, and fulfill customer demand in a timely manner. You gain unprecedented real-time visibility over all aspects of your operations, enabling improved management and optimization of your workflows.

Security is a major concern for warehouses. IoT devices allow for tracking and monitoring, thus improving the security of property, equipment, and inventory.

The IoT also enables easier control of interior environmental conditions, such as humidity and temperature. This is very useful for perishable stock like food and beverages that require a strictly controlled environment to stay fresh, extend shelf life, and prevent waste. This feature also keeps you compliant with stringent regulations.

Hence, IoT can play a key role in warehouse management by protecting against financial losses and maintaining product quality. An ordinary warehouse can be transformed into a smart hub through the use of IoT, thanks to improved adaptability, accuracy, and efficiency.

IoT in Warehouse Management Market and its Benefits

Since IoT can extend so many benefits, it has the potential to radically transform daily warehouse activities. It can amplify efficiency as well as safety while mitigating waste and high costs to facilitate intelligent warehouse operations.

Here are some of the main benefits of implementing IoT in your warehouse space:

Better Inventory Management

IoT makes in-depth data analytics possible for stock levels, condition, and location. This reduces manual work and allows better decisions by eliminating the guesswork.

With precise real-time tracking of inventory, picking items becomes much faster. This speeds up order fulfillment and warehouse operations.

Detailed inventory information gives you valuable insights that guide good management decisions. For example, you can maintain optimal inventory levels to prevent stockouts and overstocking.

Hence, IoT is the perfect complement for a great WMS for inventory management.

Is WareGo the right fit for your business? Find out with a 100% FREE trial.

Start My FREE Trial!Real-Time Tracking and Monitoring

Monitor operational progress and inventory movement in real-time using beacon technology for consistent Bluetooth connectivity.

Analysis of detailed real-time data provides deep insights to optimize your warehouse workflows.

Thanks to the continuous flow of accurate, complete, and updated inventory data, managers can detect problems before they arise. They can thus take timely action that prevents problems from transpiring in the first place.

Hence, well-implemented IoT is the perfect extension to a capable inventory management solution for transforming warehouse operations.

Get your free demo to see our cutting-edge platform live in action.

Start My FREE Demo!Improved Operational Efficiency

IoT devices facilitate automation, which helps to boost efficiency and thus save time and money.

IoT-powered devices can accelerate receiving, picking, packing, and shipping. Productivity goes up while errors are reduced.

The use of automated guided vehicles and advanced telematics greatly improves logistics speed, accuracy, and efficiency.

Reduced Waste and Cost

IoT-based climate control and lighting systems lead to reduced energy consumption.

IoT sensors on vehicles and other equipment monitor devices for temperature, vibration, and other key factors to accurately predict breakdowns in advance. You can thus act proactively to reduce equipment breakdowns and thus bring down costs.

Improved Security and Better Asset Protection

Since IoT has excellent asset tracking capabilities, it deters theft and misuse of inventory, equipment, and assets.

IoT-enabled real-time monitoring prevents safety violations in vehicles to reduce accidents, property damage, and injuries.

Employees thus have a safer working environment due to the increased safety provided by IoT monitoring.

Faster Order Fulfillment and High Customer Satisfaction

RFID tags and sensors offer real-time visibility into stock, equipment, and processes, enabling faster order processing.

IoT sensors and devices allow automatic updates of stock information. This reduces errors and stockouts, thus boosting customer satisfaction.

Hence, RFID tags and an order management system with built-in support for this technology can take your order management performance to the next level.

Our friendly experts will be delighted to explain how WareGo can bring real value your business.

Start My FREE Consultation!IoT Implementation Challenges – How to Overcome Them

Although IoT offers a wide range of benefits that can take your warehouse management to the next level, there are certain challenges to navigate before you can start reaping the benefits from this futuristic technology.

Here are the challenges that must be overcome for the smooth implementation of IoT.

Integration and Data Management

Challenge: Integrating IoT data across business systems can be an arduous challenge.

Solution: Deploy a comprehensive data management platform that consolidates data for analytics. Set up policies for data governance that provide high security as well as quality control.

Synchronization with Legacy Systems

Challenge: Integration becomes much more complex when legacy systems are in use for managing warehouses.

Solution: Make use of middleware solutions and APIs to facilitate smooth data transfer between existing legacy systems and IoT devices.

Scalability

Challenge: IoT solutions must be highly scalable to facilitate warehouse growth.

Solution: Cloud-based platforms are highly scalable solutions that let you grow without having to upgrade on-premise systems.

WareGo is the next-generation cloud-native inventory management solution that integrates with RFID to scale your business effortlessly.

Check out our price plans for the most competitive rates

Check price plans!Interoperability

Challenge: Facilitating seamless data exchange across devices from different brands may be problematic.

Solution: Consider using IoT solutions based on open standards. Carry out complete testing while deploying these IoT solutions to pinpoint and resolve interoperability issues as quickly as possible.

Change Management

Challenge: The successful adoption of IoT strongly depends on how well employees adapt to new processes and technologies.

Solution: Explain the benefits of IoT to your staff to motivate them to learn how it’s used. Show how IoT implementation results in improvements to safety, efficiency, and productivity. Identify the type of training employees will require regarding IoT processes, software, and technologies. Experiment with pilot projects of a smaller scale before rolling out a full-scale IoT solution.

Cost Issues

Challenge: IoT infrastructure entails higher initial costs. In addition, running maintenance expenses for IoT infrastructure, devices, and sensors can be substantial.

Solution: carry out a complete cost-benefit evaluation for the sake of accurately understanding ROI prior to implementing the IoT infrastructure. To reduce costs, you can rely on cloud-based solutions and implement phased rollouts.

Data Security

Challenge: IoT generates massive amounts of sensitive data related to inventory and company operations, which can be difficult to secure.

Solution: Regularly conduct thorough risk assessments and train employees on the basics of data security. Rely on security best practices and protocols like encryption, patching, role-based access control, firewalls, network monitoring, etc.

Choosing Optimal IoT Solutions

Challenge: With such a diverse array of IoT solutions, choosing the best ones for your operational needs can be a complex endeavor.

Solution: Select the best IoT system for your needs by:

- Prioritizing high scalability to easily handle future expansion.

- Ensuring flawless data synchronization with current systems.

- Deploying powerful data security to safeguard operational data.

- Accurately assessing actual ownership costs by considering both initial investments and operational costs.

By considering the aforementioned points, you can identify the optimal IoT solution that effectively meets your unique business needs. This way, you will gain the highest return on investment and experience maximum productivity benefits.

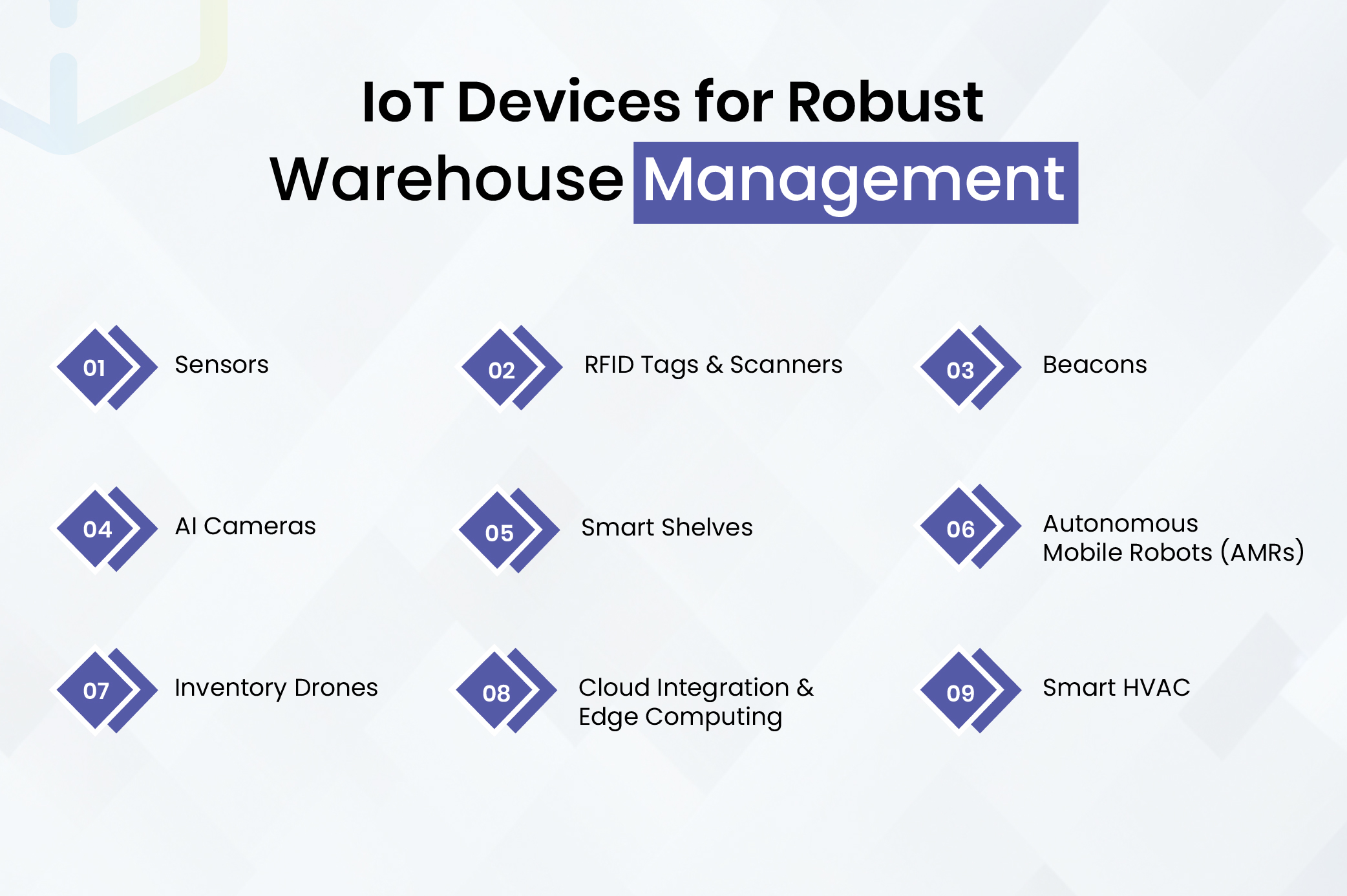

IoT Devices for Robust Warehouse Management

You can bring together various IoT gadgets in your warehouse to transform it into an intelligent fulfillment hub.

Here are the most common IoT devices in use:

Sensors

A wide variety of IoT sensors is available to track key variables, such as air quality, light exposure, humidity, and temperature, inside your warehouse. These are vital for perishable goods that require a carefully controlled interior environment.

RFID Tags and Scanners

RIFD tags are available in various shapes and forms, like semi-passive, passive, and active. These little devices may be attached to containers, pallets, and individual stock items.

RFID readers may be placed at strategic locations to automatically gather data generated by RFID tags. As a result, real-time tracking of inventory at all points of its life cycle is possible in a smart IoT-enabled warehouse. Worker productivity will go up dramatically since they don’t have to punch in the data manually – RFID does it automatically, so your workers don’t have to.

WareGo is the all-in-one warehouse management system for small businesses that supports RFID out of the box.

Our friendly experts can explain how WareGo helps.

Chat With Us!Beacons

Beacons are wireless gadgets that utilize BLE technology to enable the easy tracking of assets. This cutting-edge technology provides the precise location of items in real-time. Besides inventory, these beacons can also be installed on equipment and vehicles to track their precise movements.

Furthermore, these beacons can also track environmental variables such as temperature and humidity, making them ideal for ensuring the top quality of perishable items like food and beverages.

AI Cameras

Computer vision or AI-powered cameras can monitor the warehouse area to detect any anomaly that warrants immediate attention. For example, if a visible safety hazard is present, these cameras can issue alerts to managers.

These cameras are also useful for automating stock counting cycles as well as quality control workflows.

Smart Shelves

Smart shelves automatically count and update stock data as inventory is moved to and from these shelves. They relay this information to the WMS for documentation. Hence, you can maintain accurate stock counts without relying too heavily on manual counts that bring operations to a standstill.

They also prevent stock items from being misplaced or lost. If stock on these shelves goes below a critical level, these smart shelves issue instant alerts to prevent stockouts.

Autonomous Mobile Robots (AMRs)

AMRs leverage AI and sensors to intelligently plan and tweak their routes. These robots are engineered to work safely around people. The main function of these robots is to transport items, goods, and stock inside the warehouse to reduce the burden on human workers.

Unlike humans, these robots can work nonstop for 24 hours. This technology is not science fiction or a distant reality. Amazon is currently using around 100,000 of these smart robots for its very high-throughput warehouses.

Inventory Drones

Smart drones now have the ability to track inventory items, record locations, and scan items accurately. These drones can be useful for transporting inventory to difficult locations and during night shifts.

Cloud Integration and Edge Computing

Using edge computing, smart warehouses can process data at high speeds and provide instant analytics on demand. Cloud technology enables accurate and rapid data analysis, allowing warehouse managers to make informed, data-driven decisions quickly.

Smart HVAC

Leveraging AI-powered predictive analytics, smart HVAC systems can help maintain necessary environmental conditions with minimal human intervention. They can optimize energy consumption and thus bring down utility costs.

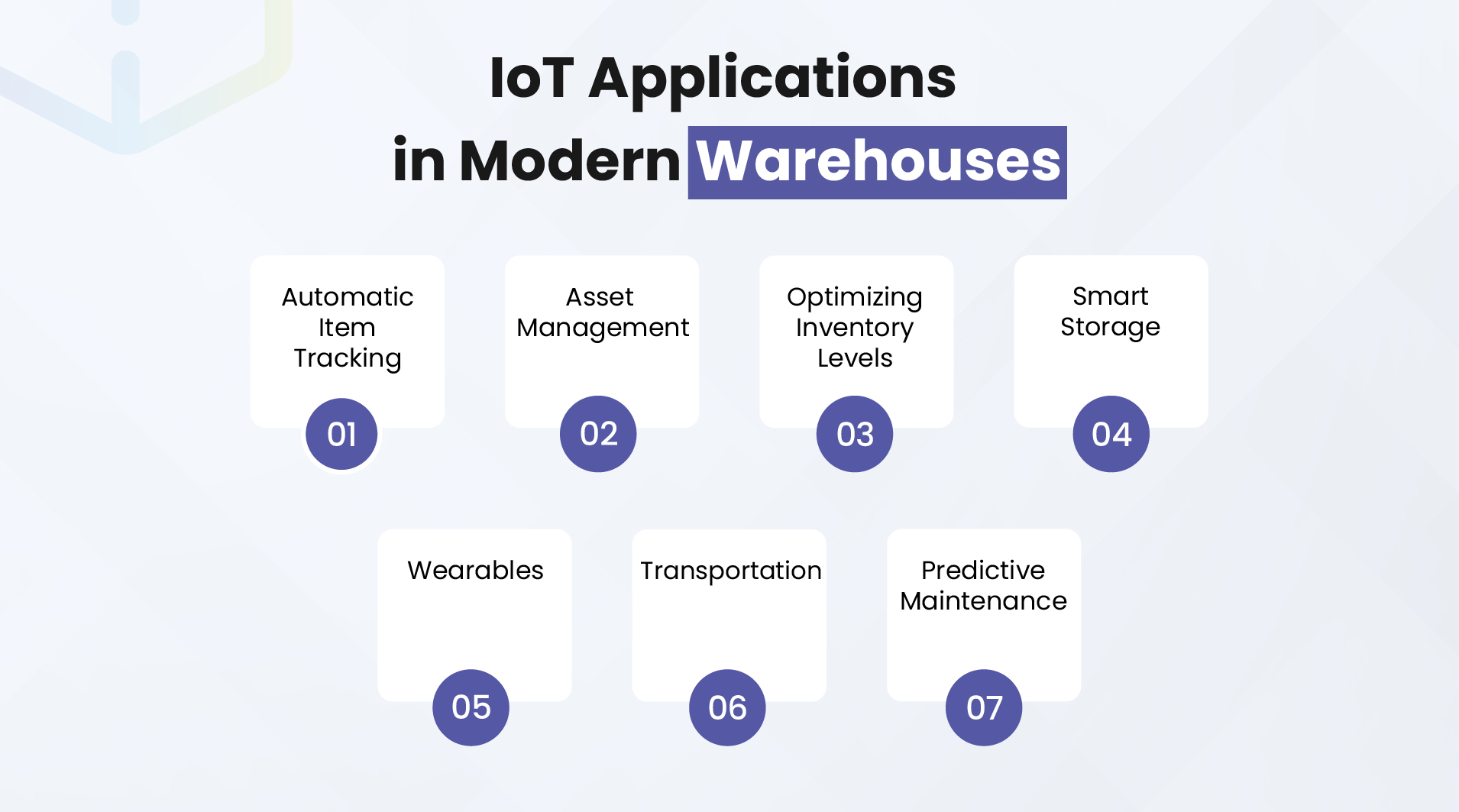

IoT Applications in Modern Warehouses

IoT devices are instrumental in the creation of modern warehouses that operate as intelligent fulfillment powerhouses. However, since each warehouse is unique, you will need to assess the warehouse’s operational needs to identify the optimal IoT processes.

Here are the most useful IoT use cases you should be aware of:

Automatic Item Tracking

Whether stock is entering or leaving the facility or moving anywhere inside your warehouse, IoT is perfect for detecting and recording real-time movement data for all inventory items.

You will need to choose optimal technology for automated detection that will efficiently exchange this data with your warehouse servers.

Asset Management

You can deploy smart sensors on inventory items, vehicles, equipment, and other property to maintain a full record of their use and movement.

Managers can use this precise real-time data to control and manage assets more effectively. For example, timely alerts on SKUs that have hit critically low levels can prevent stockouts.

Optimizing Inventory Levels

IoT can generate large amounts of useful data that can provide the basis for powerful data analysis that yields invaluable insights. Managers can make good use of these insights to make excellent data-driven decisions that bring good results.

By carefully examining this vast dataset, managers can, for example, determine optimal inventory levels that prevent stockouts, overstocking, high holding costs, and other problems.

Smart Storage

Smart shelves work in unison with cutting-edge robots and automated guided vehicles (or AGVs) to ensure the quick movement of stock items.

This streamlines the workflow while reducing the burden on warehouse workers.

Wearables

Wearables make it much easier for managers to track individual worker performances. Besides indicating their productivity, wearable devices can also provide key information like accidents, falls, and collisions.

This results in greater warehouse safety, which is a paramount concern for all companies.

Transportation

Autonomous guided vehicles can take optimized routes using GPS feed and telematic gadgets. Additionally, IoT sensors can provide accurate and comprehensive information on the movement of goods to which they are attached.

Thanks to such real-time information, managers can act proactively to prevent problems from arising instead of acting reactively after problems transpire.

Predictive Maintenance

Predictive maintenance is streamlined when IoT devices relay updated information on vibration, operational performance, temperature, and so on. The reason this method works so well is that anomalous readings can indicate the approach of equipment breakdown, allowing you to take action before it actually happens.

Hence, downtime is minimized, which prevents disruptions to your daily operations and thus saves costs.

IoT Solutions for Warehouse Management

You may feel daunted by the large investment required for IoT. Additionally, many of these futuristic technologies appear exotic because they have not yet achieved widespread adoption. This can be a cause for concern, as there is a high risk associated with cutting-edge technology that is both costly and relatively new.

However, RFID is a smart way to keep costs down by leveraging IoT tech that is relatively inexpensive, proven, and mature.

Although radio frequency control has been around since the 1940s, it really was in the 2000s that commercial RFID tech took off. That’s when its costs dropped significantly, justifying its widespread commercial use.

Walmart was one of the early adopters, and its decision to trust RFID paid off, thus starting the RFID success story in warehousing, wholesale, and retail.

So to supercharge your supply chain with IoT, you can’t go wrong with RFID – a well-established and cost-effective technology.

WareGo provides RFID support out of the box. Hence, you can effortlessly make the most of RFID-based IoT with WareGo’s trusted solution for inventory.

If you are already using barcode technology, you stand to benefit greatly by upgrading to RFID, as the latter allows for significantly faster inventory processing.

Unlike barcode scanning, where items must be scanned individually, RFID allows for bulk scanning of hundreds of RFID tags simultaneously. These tags can be scanned even through boxes and packaging and can thus speed up warehouse operations.

Whether you stay with barcode or upgrade to RFID, you can be confident that WareGo will handle either system equally well.

Not only that, WareGo also provides POS terminal support to streamline your daily activities. With each transaction, be it the purchase of inventory or the sale of merchandise, your stock levels are automatically updated. There are many other such automation features that greatly reduce manual effort, thereby minimizing errors and delays.

If you want to streamline your warehouse with IoT, consider WareGo, as it is a proven solution for both RFID and inventory management.

Is WareGo the right fit for your business? Find out with a 100% FREE trial.

Start My FREE Trial!FAQs

What is IoT in warehouse management?

IoT in warehouse management refers to the use of internet-linked sensors and devices that provide real-time data and allow the automation of warehouse processes.

Some of the most cutting-edge applications of IoT in warehouse management include the use of robots and autonomous guided vehicles.

That said, RFID tags and scanners are proven IoT devices that have been in use for decades and are also cost-effective. Hence, they are widely used by the most renowned brands for streamlining warehouse activities.

What are the four types of IoT?

Here are the four main kinds of IoT devices according to application:

Consumer IoT

Includes internet-linked sensors and devices used for personal well-being, home security, or personal convenience, such as mobile app-controlled security cameras and smartwatches.

Commercial IoT

This IoT type enables professional services and businesses (besides heavy industry) to significantly enhance inventory management and customer experience.

Industrial IoT

IoT devices are used in full-scale industrial environments, such as supply chain, logistics, energy, and manufacturing. They help with predictive maintenance, real-time tracking, and automation.

Infrastructure IoT

As the name implies, this IoT type uses sensors and networks to manage roads and other city systems, giving rise to “smart cities”.

What are the 5 C’s of IoT?

The 5 C’s of IoT ensure reliable and optimal use of IoT devices based on these principles.

- Connectivity: all IoT devices should have secure and stable wireless connectivity, even in complex environments.

- Continuity: sensors should be able to work for long time frames thanks to long battery life.

- Compliance: IoT sensors and gadgets should be fully compliant with all local and international regulations.

- Coexistence: all devices should work in full harmony without any radio frequency interference.

- Cybersecurity: Each IoT device should have maximum protection against network attacks, unauthorized access, and other such cybersecurity threats.

How is IoT used in inventory management?

IoT is used in many ways for inventory management. It can speed up inventory processing since RFID tags can be scanned simultaneously, unlike barcodes, which need individual scanning. This alone saves your workers a lot of precious time.

The flow of real-time data from inventory RFID tags allows managers to take proactive instead of reactive action. Hence, problems are resolved before they transpire, ensuring operational continuity without disruptions.

Shelves can also have IoT sensors that measure the weight or quantity of items placed on them. When stocks fall too low, they can send signals for stock replenishment, thereby mitigating the risk of stockouts.

The need for manual counts is reduced, thereby preventing disruptions to warehouse operations. Inventory level accuracy increases dramatically, reducing costly errors that lead to stockouts and lost sales.