Fulfillment happens behind the scenes and receives less public attention compared to other front-facing business processes. However, it is crucial for business success.

That’s why it pays to consider which order fulfillment method best suits your needs. We will give you a simple breakdown of how each method works, including the benefits and drawbacks of each. You can then make the right choice for your business and skyrocket productivity.

Whatever fulfillment type you go for, proven order fulfillment software can step up your game.

Our next-gen software boosts fulfillment speed and precision.

Let’s Talk!Table of Contents

Order Fulfillment – in Simple Words

Order fulfillment covers all steps of order processing – whether it is receiving orders, processing them, or shipping ordered items. Picking and packing, plus other inventory processes, are included. Strong supply chain management is paramount for timely order fulfillment.

Choosing the right method for order fulfillment can take customer satisfaction to new heights. So here is a quick rundown of the key processes for order fulfillment.

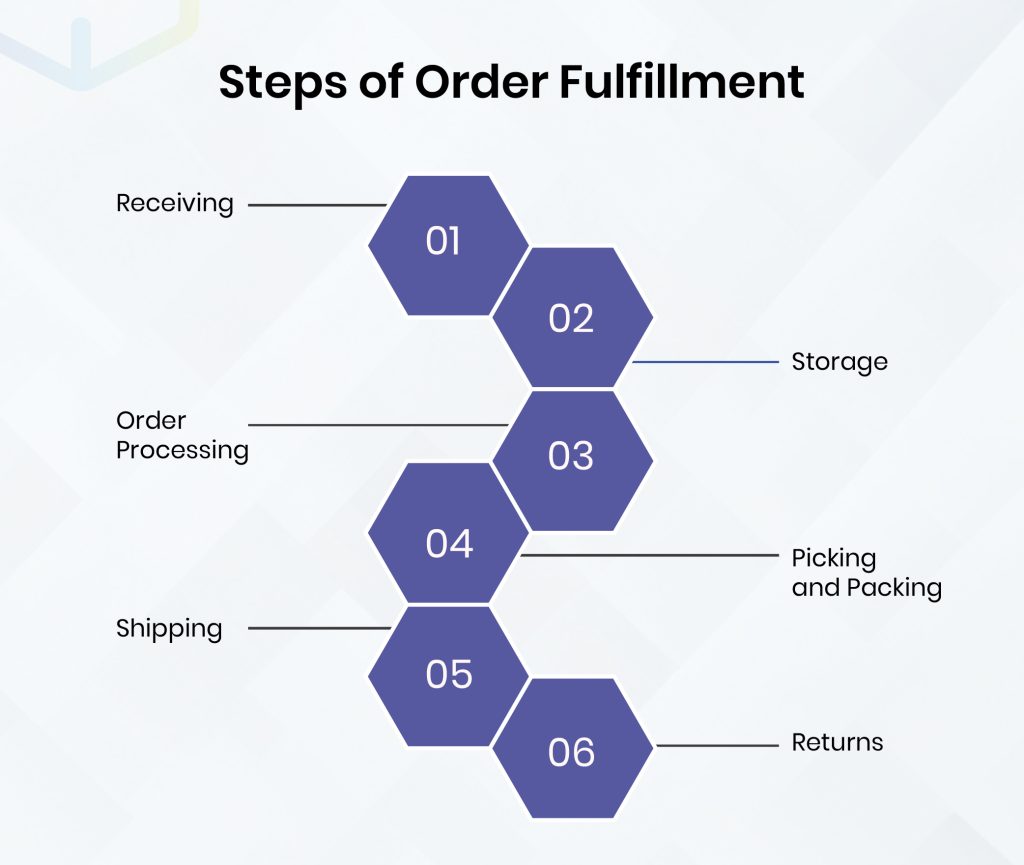

Steps of Order Fulfillment

Receiving

Order fulfillment starts with receiving. The warehouse team inspects goods received from suppliers to confirm they are of the right type, quality, and quantity.

Storage

Following inspection, goods received must be organized intelligently in the warehouse storage space for quick retrieval.

This speeds up item picking for faster order fulfillment and greater productivity.

Order Processing

If you use online marketplaces (like Amazon, eBay, Walmart) and ecommerce platforms (like Shopify and WooCommerce), then you need capable inventory software that integrates with all these channels.

Integrations allow the software to automatically update inventory data with each transaction on any sales channel. Inventory discrepancies, errors, and manual work are minimized, making multi-channel inventory management much easier.

Picking and Packing

Smart software optimizes labor schedules to maximize the order fulfillment rate. Picking may proceed in an organized way as follows.

Batch Picking: Processing orders simultaneously for high productivity.

Wave Picking: Completing similar orders to enhance efficiency.

Zone Picking: Allocating labor for each warehouse area.

Enterprise-grade inventory solutions have powerful labor scheduling features for batch, wave, and zone picking.

Barcode scanning support automatically updates inventory data with each scan. Hence, manual data entry is not required for inventory processes – fulfillment speed increases.

Shipping

Once the ordered item is picked and packed, it can be shipped to customers.

A reliable system allows you and your customers to track shipments in real-time. Customer experience and satisfaction improve.

Returns

Returns are frequent in ecommerce. That’s why you need a good returns management system to automate returns and thus maintain high customer trust.

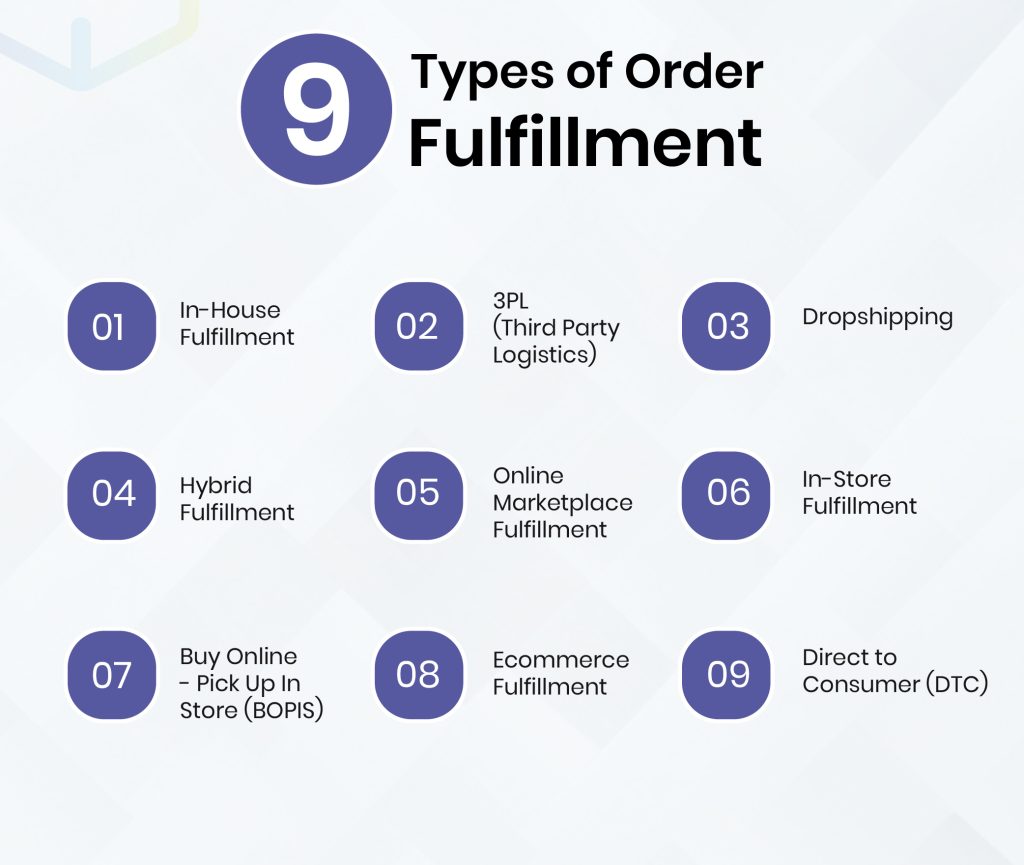

9 Types of Order Fulfillment

The right type of order fulfillment will cut costs, save time, and grow profits. Find out how each order fulfillment method works, its pros and cons, and who it is best for.

In-House Fulfillment

As implied, all steps of fulfillment are carried out internally, from A to Z. While you gain strong control over all steps of order fulfillment, it comes at a cost. You need high expertise to handle supply chain complexities on your own. Plus, heavy investments are required for warehouses, vehicles, and equipment.

Pros

- Better control over the supply chain

- Flexible packaging quality and cost

- Faster response to changing demand

- Can negotiate better terms with suppliers and customers

Cons

- Big investment needed for warehousing and transport assets

- Effort-intensive – consumes more time and effort

- You may have less time for your core business

- Requires strong experience and deep expertise

- Fluctuating demand and supply challenges bring greater risks

Best for

Large enterprises with big budgets who desire greater control over their supply chain, for example, manufacturers who need timely shipments for just-in-time inventory.

Gain full control with real-time visibility using our software.

Book FREE Demo!3PL (Third Party Logistics)

3PL stands for third-party logistics. Order fulfillment is fully outsourced to a specialist 3PL service provider.

The 3PL service provider takes care of receiving, storing, processing, and shipping your inventory. They manage all logistics assets like warehouses and vehicles.

SMEs can save a lot of money this way, since 3PL partners provide necessary resources like warehouses. Outsourcing to a 3PL partner saves you time and effort since you don’t have to manage time-consuming fulfillment.

Well-established 3PL partners can boost your customer experience with faster and more accurate order fulfillment.

Pros

- Saves heavy investment on logistics assets

- Saves plenty of time and effort.

- Simplifies inventory management

- Faster order fullfilment

- Fewer fulfillment errors and shipping delays

- Improves customer satisfaction

Cons

- Less control over logistics

- Quality 3PL service requires dependable partners

- Recurring 3PL service payments

Best for

SMEs (small and medium sized businesses) who want to focus on their main business, simplify logistics, and cut costs. While they have less direct control over logistics, the benefits outweigh this caveat.

Dropshipping

Under dropshipping, you serve as the marketing and sales front for a manufacturer. You promote products for the manufacturer and take customer orders via a website. The manufacturer fulfills all customer orders you bring them. Since you manage just online marketing and sales, dropshipping is fairly simple and very low cost.

Pros

- No need to buy or manage inventory

- Very low cost

- Simple – just online sales and marketing

Cons

- No control over order fulfillment

- No ownership over brand or products

- Commission based earnings only

Best for

Freelancers who like to work from home with minimal investment risk.

Hybrid Fulfillment

Hybrid fulfillment combines two or more of the above models for flexibility. For example, your business can fulfill certain products in-house and outsource complex items to 3PL services.

You maintain strong control (with in-house fulfillment) and simplify inventory with 3PL outsourcing. Hence, you gain the best of both worlds with the hybrid approach.

Pros

- Less complexity

- High scalability

- Provides good level of control

- Great for peak seasonal demand

Cons

- Less control than in-house fulfillment

- Managing two fulfillment models has its own set of complexities

- Higher cost than 3PL-only fulfillment

Best for

Growing brands that need a good level of control, plus flexibility. By fulfilling most products in-house and outsourcing the most complex inventory, SMEs can strike the right balance between cost, control, and complexity for order fulfillment.

Online Marketplace Fulfillment

Popular online marketplaces like Amazon, eBay, and Walmart offer high-quality fulfillment services. These services invest heavily in automation technologies for fast and precise fulfillment.

They handle inventory storage, packing, shipping, and returns.

You gain access to a vast customer base with online marketplaces. However, these platforms have high competition.

Pros

- Efficient order fulfillment

- Access to 10s of millions of customers

- Integrations enable effective inventory management

Cons

- Expensive

- Increasingly stiff competition

- Restrictive terms and conditions

Best for

Startups and small businesses with no experience in fulfillment that need the simplest solution for efficient order processing. This fulfillment model also suits those trying to diversify their sales channels.

In-Store Fulfillment

Brick and mortar stores serve 2 purposes here – retail and online fulfillment. Established retailers can sell online without major investments just by using their existing assets.

Customer experience improves since in-store fulfillment allows in-store and online shopping.

Increased flexibility improves the buying experience and provides freedom of choice.

Pros

- Fast shipping

- No extra investments

- Low shipping costs

- Online and instore shopping

- More flexibility for customers

Cons

- Limited space for warehouse

- Consumes limited retail space

- More work for employees

Best for

Items like jewelry, sports goods, cosmetics, and home decor that need to be handled by customers before buying.

Buy Online – Pick Up In Store (BOPIS)

As implied, customers order products online and pick them from your store. This works for customers who can’t stay home for deliveries.

Here’s a major plus point: customers often buy more when they come to your store.

Since customers can check items in store, this means fewer returns.

In-store shopping boosts engagement, increasing customer loyalty.

Pros

- Flexibility and convenience for customers

- Eliminated delivery costs

- Fast order fulfillment

- Customers often buy extra

- Online sales targets more customers

- Fewer returns

Cons

- Some customers need home deliveries

- More work for employees

Best for

Businesses that deal in garments, crafts, shoes, and so on, where customers first need to personally check the item before buying it.

Ecommerce Fulfillment

An ecommerce website is your online store for selling goods on the web. Unlike online marketplaces (such as Amazon), you run an independent sales platform.

Online ads and SEO blogs are crucial for promoting your products, engaging buyers, and driving ecommerce sales.

Ecommerce has benefits, like global reach and lower running costs. However, newcomers may struggle to find buyers due to a lack of online trust.

Higher delivery times can impact the buying experience. Ecommerce also suffers from more frequent product returns compared to traditional retail.

Pros

- Wide reach, large audience

- No need for physical store

- Website automatically takes orders

- Lower costs than traditional retail

- Flexible fulfillment options

Cons

- High shipping costs

- Longer fulfillment times

- SEO is increasingly competitive

- Online ads require payment

- Website maintenance costs money

Best for

Niche products that are not commonly found in retail stores, like subscription boxes, rare health and beauty products, and handmade goods. Also, well-known brands can leverage buyer trust to sell via ecommerce.

Direct to Consumer (DTC)

Here, a manufacturer sells directly to consumers by independently managing all retail, supply, and manufacturing itself. Avoiding 3rd party wholesalers, retailers, suppliers, and marketers means significant cost savings.

The company can hence charge the lowest prices.

D2C allows full control over product quality, customer experience, logistics, and other key matters.

But it is far more complex since you have to take care of everything. Heavy investments in manufacturing, logistics, and retail are necessary.

Pros

- Eliminates payments to 3rd parties

- Competitively priced products

- Full control over brand experience

- High profit margins

- High customer satisfaction

Cons

- Requires heavy investments

- Complex management

Best for

Large enterprises with the budget and expertise to handle all business functions themselves.

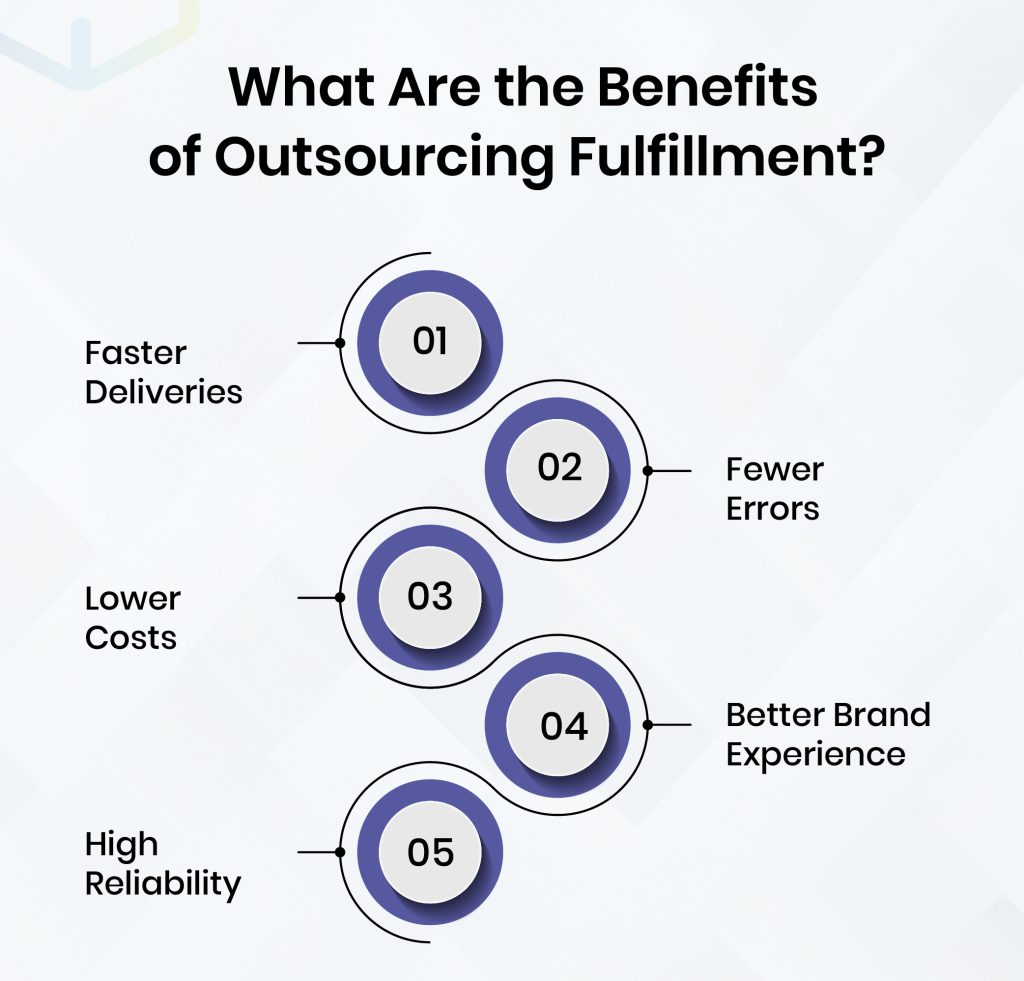

What Are the Benefits of Outsourcing Fulfillment?

Outsourcing fulfillment can bring several benefits for your business. Here are some of them.

Faster Deliveries

3PL service providers run highly efficient warehouses for rapid fulfillment. Customers are more likely to return when you supply on time.

Fewer Errors

3PL service providers rely on automation to reduce manual work and errors. High order accuracy boosts customer satisfaction.

Boost fulfillment accuracy and speed with our software.

Book FREE Trial!Lower Costs

You won’t have to invest in warehouses, vehicles, and equipment with outsourced fulfillment. Cash flow improves and you save a lot of money in the long term.

Better Brand Experience

3PL services package ordered items very safely to reduce damage in transit. It shows customers you care for them. You get more repeat business this way.

High Reliability

Whether its fluctuating demand or fast growing orders, 3PL services are up to the task thanks to streamlined fulfillment processes and infrastructure.

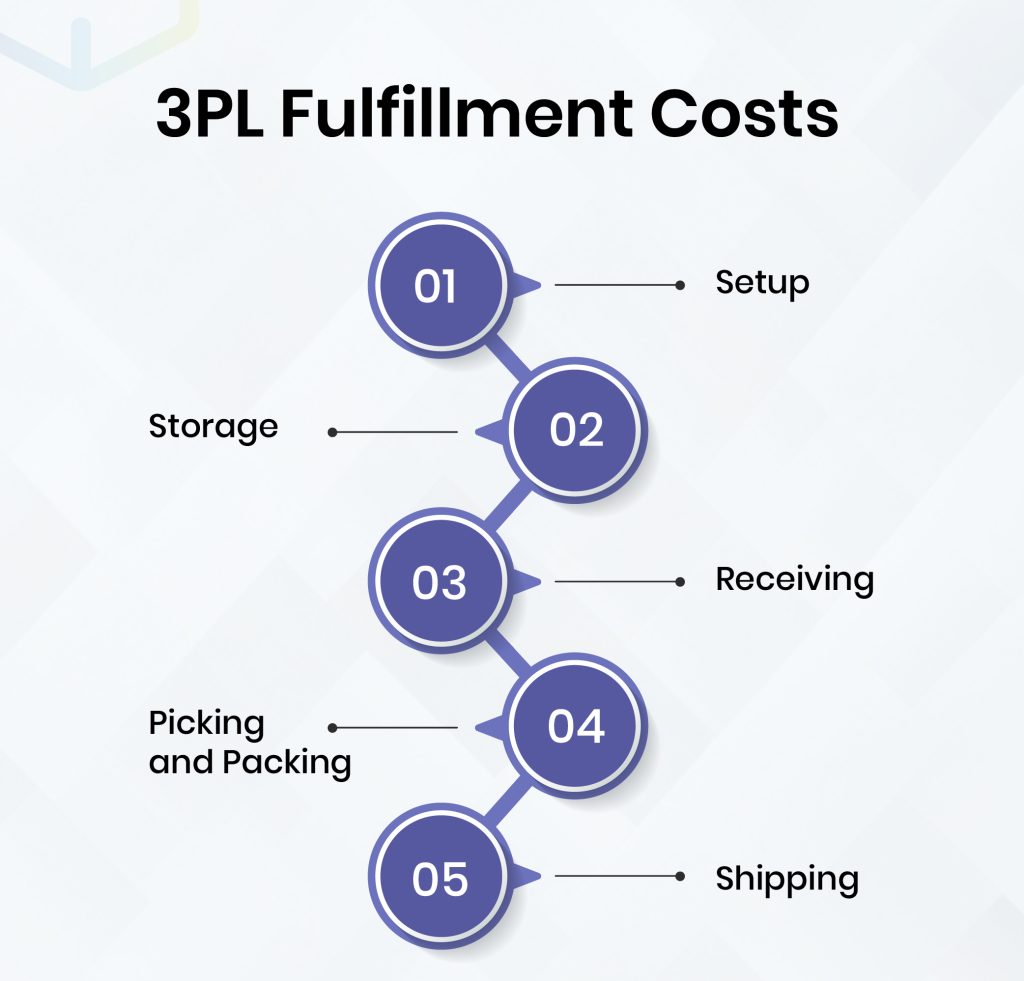

3PL Fulfillment Costs

Here are the fees to consider when choosing a 3PL partner.

Here are the fees to consider when choosing a 3PL partner.

Setup: The 3PL service provider will take a fee for syncing inventory, integrating technology, and arranging the first batch of your inventory.

Storage: Charged per cubic foot or pallet used for storage. More storage space means higher storage costs.

Receiving: The amount charged by the 3PL for receiving new inventory shipments.

Picking and Packing: Fulfilling customer orders requires labor and consumes packaging materials.

Shipping: This is the cost incurred for delivering items to your customers.

Besides these, a minimum level of 3PL service is required each month. This varies by service provider. Failing to order this service level means extra fees. Investigate these costs and terms before choosing any 3PL service.

Fulfillment Technologies

Various technologies are used to speed up fulfillment operations. Here are the most important.

Inventory System

No matter what fulfillment method is used, a powerful inventory system is needed for efficient operations.

Enterprise-grade software provides inventory control, supply chain management, forecasting, reports, analytics, integrations, and more.

A good system cuts inventory costs, speeds up fulfillment, reduces errors, automates manual work, and provides several other benefits.

Streamline inventory management with out comprehensive software

Start Consultation!Automation

You can boost productivity, slash errors, and reduce manual work with automations. Integrations are key in this regard, since they share your inventory data with other business software – no need to manually enter data into these systems.

Automatic stock replenishments are also vital since they purchase stock automatically when inventory falls below critical levels. Stockouts, disruptions, and customer dissatisfaction are minimized as a result.

AI-powered forecasts speed up demand planning and improve forecast accuracy. Accurate forecasts prevent excess inventory and high holding costs.

Automate your processes and slash errors with our inventory solution.

Chat with Us!Barcode Scanning

Barcode scanning greatly improves speed and precision for all inventory processes like picking, packing, receiving, storage, and shipping.

Workers can complete any transaction with just a barcode scan – no need to manually enter data.

Manual effort and errors both go down, since barcode support automatically updates inventory data with each barcode scan.

RFID is an evolution of barcode scanning and a gamechanger for busy warehouses. Unlike barcodes, workers don’t have to scan RFID tags. Preinstalled RFID scanners simultaneously detect multiple tags as workers move inventory around the warehouse.

Enjoy flawless barcode scanning support with our inventory software.

Let’s Talk!Order Fulfillment Challenges – and their Solutions

Here are the main order fulfillment challenges and their solutions.

Stockouts

Stockouts lead to lost sales and disappointed customers. A capable inventory system prevents stockouts with real-time tracking and automatic stock replenishment.

Overstocking

Overstocking restricts cash flow and raises holding costs. Accurate AI-powered forecasts suggest the minimal inventory level required to fulfill demand without overstocking.

Inaccurate Inventory

Inaccurate inventory data leads to stockouts, fulfillment errors and lost sales.

Manual data entry is the root cause of this problem.

Certain technologies eliminate error-prone manual data entry by automatically updating inventory data. Here are some of them.

- Barcode Scanning: With barcode support, workers can simply scan inventory after completing a process to update inventory data – no need for manual updates.

- Omnichannel Support: Updates inventory data automatically each time there is a transaction on any sales channel.

- Integrations: Automatically supply inventory data to your business software without manual data entry.

Returns

Customer returns are a reality you can’t ignore. Accurate returns processing is necessary to preserve customer satisfaction.

That said, customer returns are extra work for your busy staff.

Hence the need for a proven returns management system to automate this key process.

Long Picking Times

Improper inventory organization and misplaced units cause slow item picking. If not resolved, the order fulfillment rate slows down.

Powerful inventory software resolves these problems using:

- ABC Classification: Places fast-moving goods closer to workers and slow-moving goods deep inside the warehouse. The average travel distance declines and item picking accelerates.

- Serialization: Assigns unique number sequences to each SKU – workers can quickly locate items without mixups or mistakes.

- Slotting: SKUs are placed logically for quick retrieval – for example, similar items are grouped together. Reduces worker travel distance.

Resolve all fulfillment challenges immediately with next-level fulfillment software.

Book FREE Demo!Bottom Line

No matter what fulfillment type you opt for, one thing is for sure. You need a battle-tested inventory system to streamline the fulfillment process.

Our software offers enterprise features at knockdown rates.

Let’s Talk!FAQs

What are the different types of fulfillment?

The different types of fulfillment are:

- In-House Fulfillment: Self-managed fulfillment maximizes control over shipping times, cost, and order accuracy.

- 3PL (Third Party Logistics): Outside experts fulfill customer orders with speed and precision, saving you time and money.

- Dropshipping: You sell a manufacturer’s products online. The manufacturer handles order fulfillment – not you.

- Hybrid Fulfillment: Combines two or more fulfillment methods, for example, in-house plus 3PL fulfillment.

- Online Marketplace Fulfillment: Companies like Amazon and eBay fulfill orders you receive through their online marketplaces.

- In-Store Fulfillment: Customers order online and collect their items at a store that is both a retail outlet and a fulfillment center.

- Buy Online – Pick Up In Store (BOPIS): Rather than receive home deliveries, buyers pick up their online orders from a fulfillment store.

- Ecommerce Fulfillment: Online selling and order fulfillment via your own ecommerce website.

- Direct to Consumer (DTC): From product manufacturing to direct customer shipments, the manufacturer manages all processes themselves – without any 3rd party.

What are the 7 steps of order fulfillment?

The 7 steps of order fulfillment are

- Receiving: staff receive shipments from suppliers and inspect them to confirm that all items are of the correct type and quantity.

- Storage: Received inventory is organized intelligently to facilitate fast item retrieval.

- Picking: Workers pick items ordered by customers.

- Packing: Ordered items are packed safely to prevent damage in transit.

- Shipping: Freight services transport packed items to a fulfillment center close to customers.

- Delivery: Packed items are delivered to waiting customers.

- Returns: Items returned by customers arrive at a fulfillment center for returns processing.

What are the three fulfillment methods?

The 3 most popular fulfillment methods are:

- In-House Fulfillment: The company manages fulfillment from A to Z without any 3rd party.

- 3rd Party Logistics: Fulfillment is outsourced to a logistics company (3PL service provider).

- Dropshipping: You sell a manufacturer’s products online, while the manufacturer handles all of order fulfillment – from manufacturing to shipment.

What does fulfillment type mean?

Fulfillment type can refer to various fulfillment models. These include

- In-House Fulfillment

- 3PL (Third Party Logistics)

- Dropshipping

- Hybrid Fulfillment

- Online Marketplace Fulfillment

- In-Store Fulfillment

- Buy Online – Pick Up In Store (BOPIS)

- Ecommerce Fulfillment

- Direct to Consumer (DTC)