Managing a cold storage facility is a task. Between constantly changing temperatures, perishable goods, and demand for accuracy, the pressure becomes real.

Customers expect ideal order accuracy, and it’s not easy to manage inventories and shelf lives of perishable goods while minimizing energy cost.

This is precisely why cold storage WMS cost becomes a savior. It offers strategic techniques to create a budget line for business profits.

Cold storage WMS typically ranges from $100 to $500 per month, which is a necessary investment considering the challenges you face in a cold storage facility.

According to recent research, the Global cold chain storage market size is projected to increase from $12.5 billion to $25.19 billion by 2028, meeting the growing needs of the economy.

In this blog, we’ll explore the cost of cold storage WMS, including its breakdown and potential solutions. Additionally, let’s identify the period to set up a cold storage warehouse management software and analyze the factors that affect it.

Seeking the optimal plans for your cold storage facilities? Start with WareGo's custom plans for you!

Get a Free Consultation Now!Table of Contents

Cold Storage Management Cost: The Detailed Overview to Choose

Unlike other WMS platforms, cold storage management system software is built to handle perishable food & goods logistics in ultra-low temperatures.

The average cost of a cold storage warehouse management system ranges from $5,000 to $30,000, depending on the business size, level of automation, and other features.

Before examining the cost components, let’s review the basic price estimate based on business size.

| Business Size | Estimated Price (Monthly) |

| Small-sized | $100 to $500 |

| Mid-Sized | $500 to $5000 |

| Large-scale | $500 to $25000+ |

Detailed Cost Breakdown for Cold Storage WMS

| Cost Components | Cost Range | Details to Choose |

| On-premise WMS (one-time) | Estimated $2500 per facility. | For an in-house data business. |

| SaaS WMS for refrigerated warehouses. | Range from $100 to $500 per month. | It has subscription-based models with lower costs. |

| Implementation+ Setup | Starts from $10000 to $25000 | It covers the initial cost of running the software. |

| Hardware ( temperature monitoring, sensors, IoT devices) | It can be from $5000 to $15000 | Specific hardware for censoring and monitoring. |

| Onboarding and training | Its annual cost is $5000 to $2000 | To train onboarded staff. |

To get a clearer view of the cost of a cold storage WMS, feel free to use our calculator to estimate your costs for free.

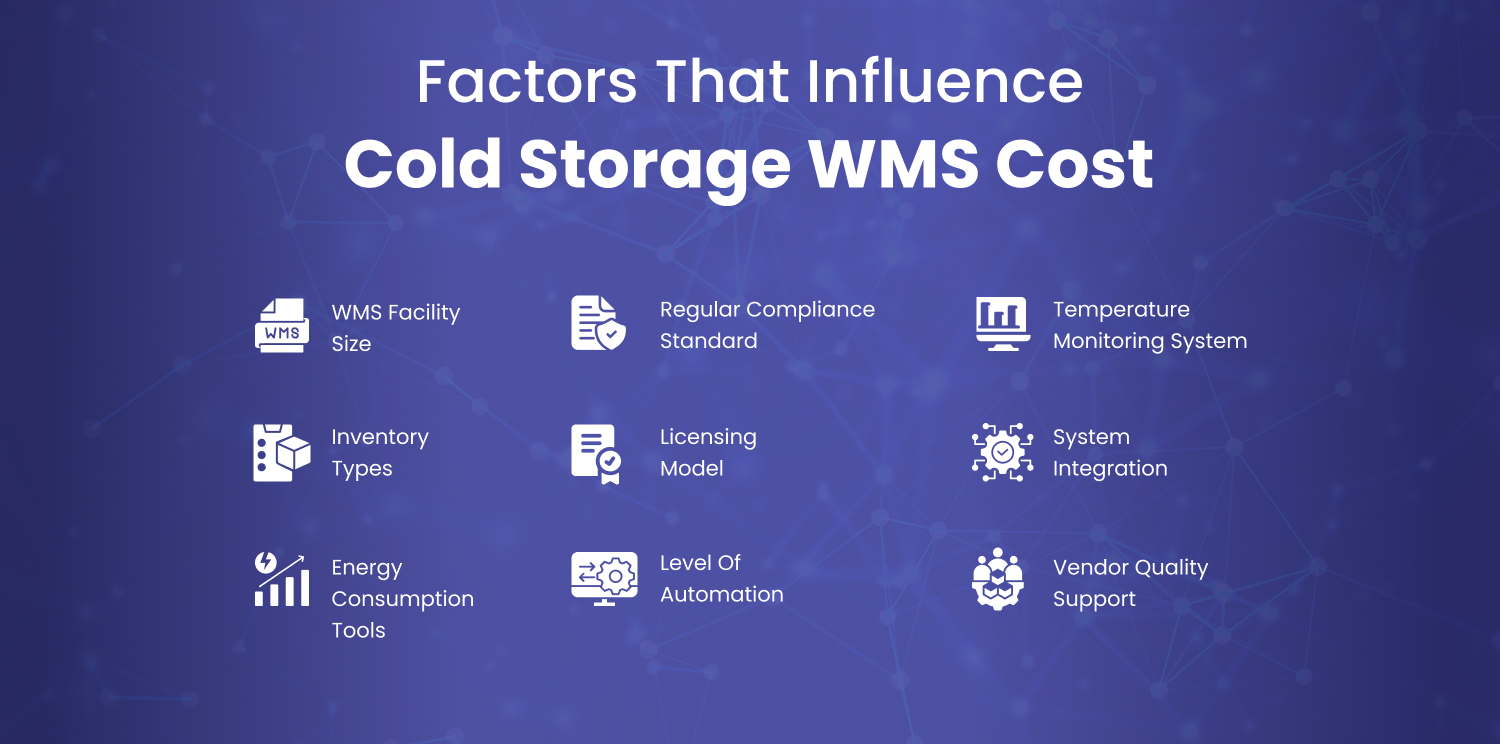

Contact Now!Factors That Influence Cold Storage WMS Cost

Before determining the automated cold storage warehouse software cost, it’s essential to understand what truly drives the cost.

Here is a closer look at the factors that impact your cost of cold storage WMS.

Let’s begin!

| Factors | Description | Cost Impact Level | How to optimize it |

| WMS facility size (U.S.-based) | The average cold storage facility is approximately 100,000 sq ft, which means larger spaces require more sensors, user licenses, and other devices for enhanced safety. | High | Build a WMS from the ground up so it grows with you over time. And pay for anything you use. |

| Regular compliance standard | Highly regulated sectors need advanced WMS features for audits & reporting. | High | Select a WMS with pre-compliant features to avoid additional installation charges. |

| Temperature monitoring system | Managing perishable inventories by automated sensors to know if something is outdated or spoiled. | Medium | Find a WMS with automated alerts and sensors. |

| Inventory types | Some goods require specific software settings, such as medicine or frozen foods. | High | Plan your inventory to prevent extra charges. |

| Licensing model | SaaS subscriptions are usually affordable and easy to get started. | Medium | Opt for Saas if you are a startup or hybrid business. |

| System integration | Integrate WMS with IoT platforms, ERP, CRM, and TMS. | High | Use open AI-compatible WMS. |

| Energy consumption tools | 30% to 70% of the energy is consumed in cold storage WMS costs. Predictive analysis can reduce the bills by 30% | Medium | Invest in innovative technology tools to proactively manage usage & save long term. |

| Level of automation | Automated racking systems and conveyor systems require specialized WMS, which involves development expenses. | High | Fix a WMS that already supports automation & avoid costly middleware. |

| Vendor quality Support | Vendors offering full live customer support, onsite visits, and may increase fee charges, but provide help in achieving a better return on investment (ROI) | Medium | Find vendors with high CSAT ratings. |

Hidden Cost of Cold Storage WMS

As we consider the main costs and other factors of cold storage WMS, it often includes some hidden expenses that significantly impact the business’s profitability.

These hidden costs include customization, integration with existing tools, maintenance, and staff training.

Many businesses overlook the hidden costs and bear the weight later on.

Let’s discuss the following hidden cost that is quietly impacting the business.

| Hidden Cost | What the Cost is About | Impact Level |

| Customization | Adapting customizations for WMs to handle temperatures to cold chain needs like ( Vaccines, seafood) | Medium |

| Integrations | Syncing ERP, TMS devices. | High |

| Migrate Data | Transferring data into a new WMS. | Medium |

| Maintenance | Need more paid softwares. | High |

| Inefficient Processes | inefficiencies in warehouse operations, such as longer picking times and increased travel distances. | High |

| Consultancy Fees | Setup advice & external support fee. | Medium |

| Hardware Charges | Installation of extra scanners & printers. | Medium |

| Downtown Fees | Paying extra for faster services from vendors. | Low to medium |

Smart Saving Tips of Cold Storage WMS to Reduce Hidden Cost

Now that we are aware of several hidden costs, let’s discuss how to overcome them and work efficiently to generate profits for your business.

- Reduce labor and manual errors with the help of automation.

- Focus on must-have cold storage WMS that covers almost every feature of your requirement.

- Track & improve real-time dashboards to identify waste and address it promptly.

- Maintain and install cooling systems to prevent hot leaks.

- Train and retain experienced staff who are knowledgeable about cold storage and its maintenance.

- Look beyond initial pricing, think long-term.

WareGo is ready to help you with a budget-friendly warehouse management system for cold storage.

Talk to our Experts!Other Considerations That Influence Cold Storage WMS Cost

Sometimes, several factors significantly affect the overall expenses beyond just the initial cost.

These include numerous factors, such as automation, maintenance & support, among others. Some of them include;

Customization Needs and Automation

More advanced customization in automated cold storage warehouse software boosts efficiency, but increases setup and maintenance costs.

Maintenance and Support

Regular maintenance and WMS implementation costs often include ongoing updates and daily system health checks. Ask for extra charges sometimes.

Users and Transaction Volume

Many WMS solutions charge based on the number of users or the volume of transaction processing, which raises the total cost of temperature-controlled WMS.

Compliance Regulatory

Cost storage primarily performs operations on WMS for perishable goods to regulate compliance and prevent spoilage-related losses.

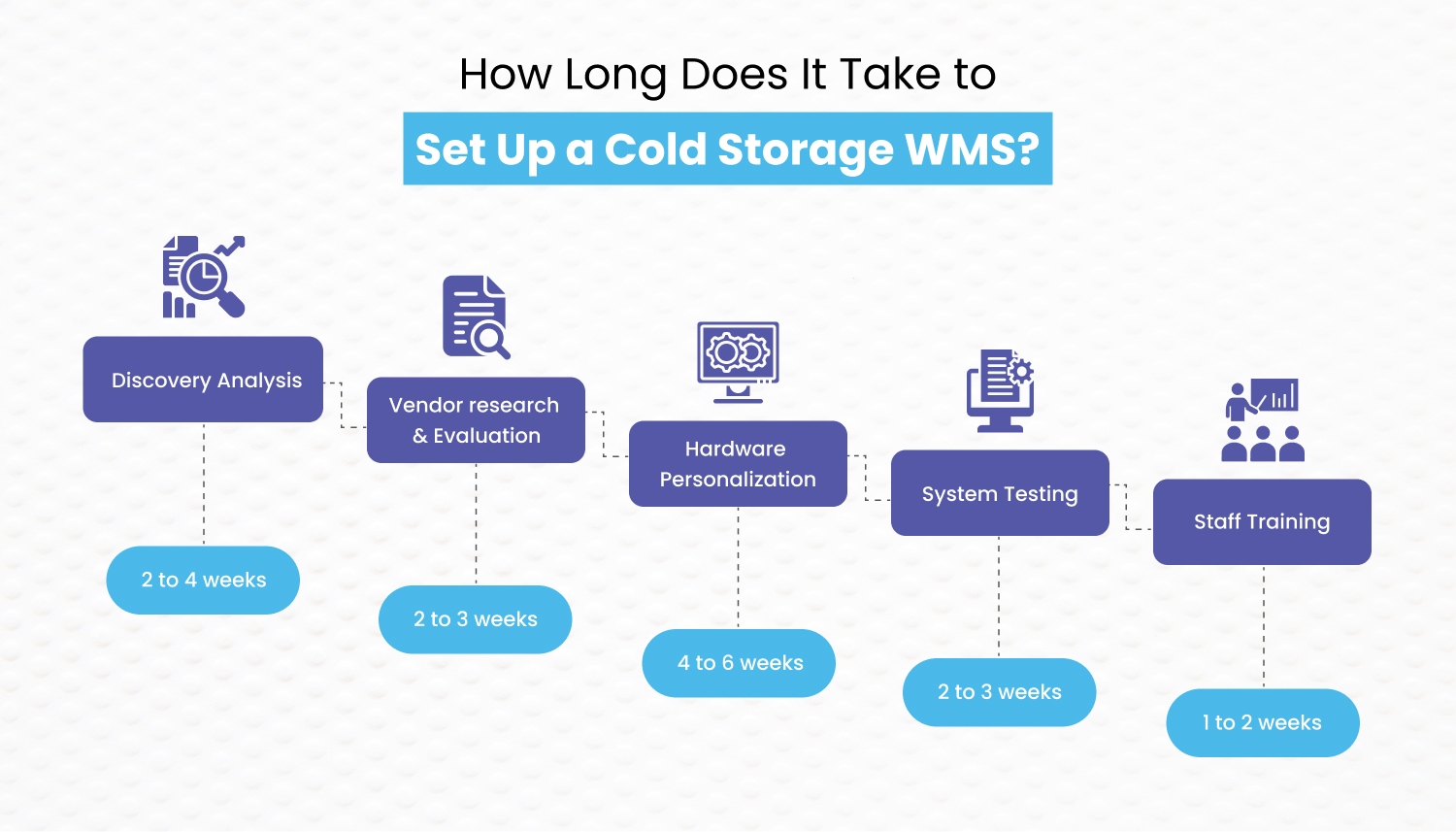

How Long Does It Take to Set Up a Cold Storage WMS?

Let’s be specific. Now that we have all this information, we can determine how much time your business will take to set up a cold storage WMS. Typically, the complete setup takes around 12 to 20 weeks.

However, the next question is how to proceed?

Setting up software isn’t just easy; it requires planning, the right vendors, and on-point system readiness.

The timeline requires measurements and proper terms, such as facility size: automation level, energy consumption tools, and basic needs.

Here is a realistic estimate of the time to expect.

| Phase for Implementation | Timeline | Process Highlights |

| Requirement & Discovery Analysis | 2 to 4 weeks | Find warehouse needs, temperature zones, and compliance standards. |

| Vendor research & Evaluation | 2 to 3 weeks | Compare vendors, assess IoT compatibility, and then select the best option among them. |

| Software & Hardware Personalization | 4 to 6 weeks | Install sensors, and customize WMS. |

| System Testing with Quality Assurance | 2 to 3 weeks | Test real-time performances and record cold storage conditions. |

| Staff Training & System Enablement | 1 to 2 weeks | Set safety protocols, train staff. |

Final Takeaways – Build an Efficient Cold Storage Warehouse with WareGo

Don’t wait for the disaster to make a change! Make it now with cold storage WMS cost; open all ways to grow. No need for high budgets & professional teams, we have got you covered.

WareGo provides a system designed to handle the challenges your warehouse faces every day.

As the world is heading towards stricter regulations, energy-efficient wms will define the leaders in this space.

Partner with WareGo to make your problem ours & discover Cold Storage Facilities without any hustle.

Schedule a Demo!Frequently Asked Questions – FAQS

What is cold storage wms?

A Cold storage wms is software that helps track and manage inventories, arrange perishable items, and maintain temperatures in a refrigerated or frozen warehouse environment.

What are the main factors that affect cold storage cost?

Factors that affect cold storage WMS costs can vary from one another, but this is not a barrier to effective management. Some of the main factors are;

- Facility Sizes.

- Temperature-controlled WMS.

- Level of automation.

- Regular compliance standard

- Temperature monitoring system

- Inventory types

- Licensing model

- System integration

- Energy consumption tools

What is the difference between cold storage & regular wms?

In cold storage WMS, the primary goal is to manage perishable items, such as goods, frozen items, or medicine, which are typically associated with expiration dates. In regular WMS, the main goal is to focus on general inventory control and order fulfillment within the warehouse.

Is cloud-based cold storage wms more cost-effective than on-premise?

Generally, it depends; however, cloud-based WMS is more effective than on-premise. The reason behind it is lower upfront cost and minimal maintenance requirements. As they follow a subscription-based model, expenses become more predictable.

Can a cold storage wms reduce operational costs in the long run?

Yes, a cold storage WMS can significantly reduce operational costs over time. A cold storage WMs optimizes labor productivity, minimizing energy consumption with better temperature zones and improving inventories. A WMS helps eliminate inefficiencies and reduce waste, ultimately saving your time and money.