OEM and ODM are 2 different product design and manufacturing models. The best one for your needs depends on your financial standing and technical expertise. That said, both models require reliable warehouse management software to work.

Before getting into it all, you should know what exactly each acronym stands for, plus its pros and cons.

Our software has all you need for next-level manufacturing and inventory management.

Let’s Talk!Table of Contents

OEM and ODM

OEM

OEM stands for Original Equipment Manufacturer. Here, the customer provides the product design to an OEM factory, which manufactures products for the customer according to this design.

ODM

ODM is short for Original Design Manufacturer. The manufacturer handles both product design and manufacturing itself. Customers can put their brand name on these products and sell them. Hence, ODM is all about white-label products.

ODM vs OEM: The Main Differences

The main difference between ODM and OEM is design ownership.

In OEM, the customer owns the product design and related intellectual property rights. The OEM factory simply manufactures them.

In ODM, the manufacturer owns the product design and related intellectual property rights. However, customers can apply their branding to these products and sell them.

Here is a summary of the key differences between the two models.

OEM | ODM | |

| Product Design | The customer designs the product. | The manufacturer provides the product design. |

| Intellectual Property Rights | The customer owns these rights for the product. | The manufacturer owns these rights for the product. |

| Investment | Customer invests in product R&D | The manufacturer invests in product R&D |

| Branding | Product has your brand, no one else’s. | White-label – other brands sell the same product. |

| Risk | High – Uncertain demand since the product is new. | Low – Proven ODM products have market share. |

| Product Customization | Full control over product customization. | None – can customize only packaging and branding. |

| Competition | Low – if your product is innovative | High – others sell the same generic product as you. |

Now that you know the differences, let’s dive into the details, including pros and cons. Here’s what each model means for your unique business.

Original Equipment Manufacturer (OEM)

An OEM or Original Equipment Manufacturer builds products for a customer based on design specifications provided by the customer.

A good example of OEM would be Foxconn. Apple designed the iPhone in-house and then contracted Foxconn to manufacture it based on Apple’s own design specifications.

So with OEM, the customer is fully responsible for product R&D – research and development. This brings great risks and rewards as explained below.

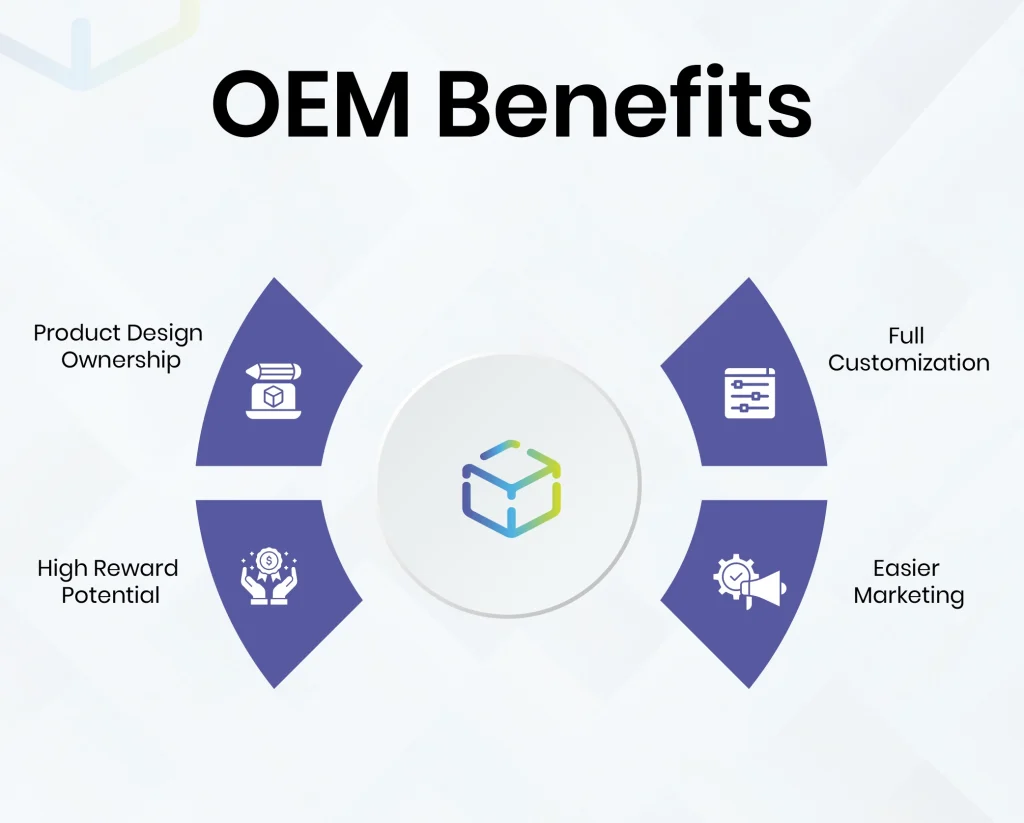

OEM Benefits

Product Design Ownership.

A key benefit of the OEM approach is that you retain full control over product design. Hence, there are no intellectual property restrictions on switching manufacturers if required.

So when needed, you can switch to better manufacturers for significant long-term benefits.

Full Customization

With OEMs, you enjoy full flexibility over product design. That is, you can change the design whenever needed.

You can incorporate new features, introduce innovation, and optimize your products according to customer feedback.

Such flexibility does not exist for ODM.

High Reward Potential

Although R&D requires a lot of effort and resources, it can pay big rewards if done right.

For instance, Apple invests substantial amounts in research, taking months, if not years, to make each product. But thanks to fantastic R&D, Apple has captured the market and become the most valuable company on earth.

While the risks are high, so are the rewards.

Easier Marketing

The OEM model allows businesses to develop unique products that truly stand out. Marketing becomes easier since such products offer unique, innovative features that rivals can’t provide.

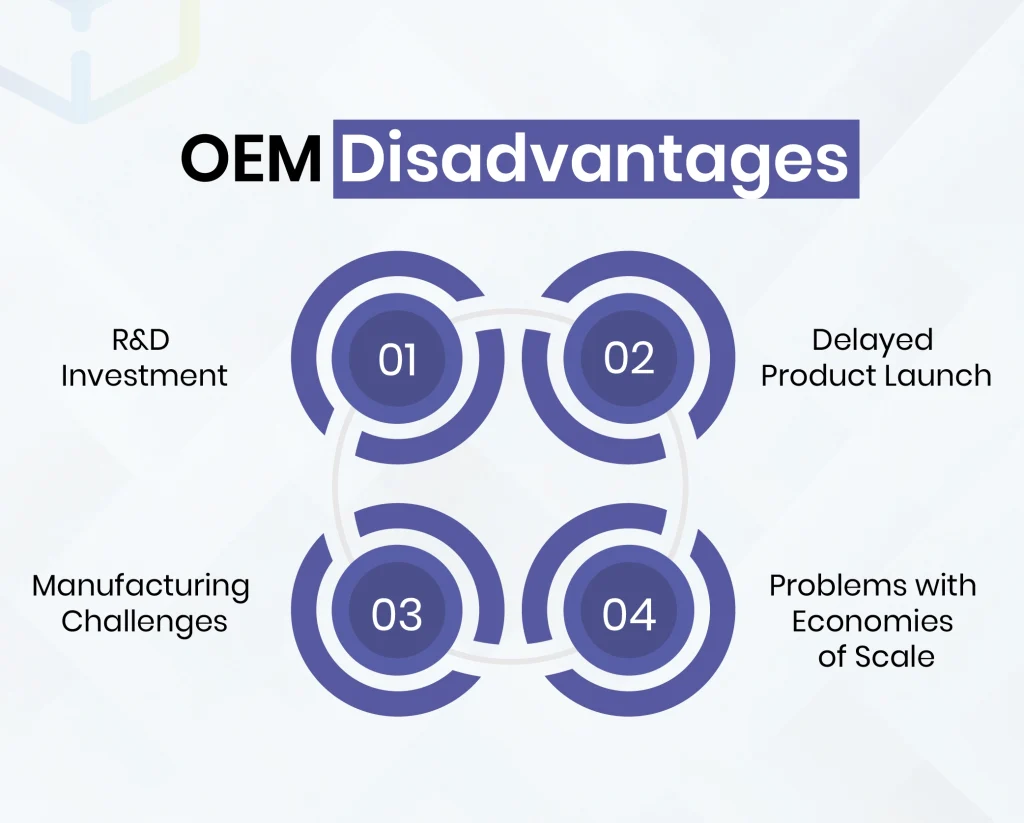

OEM Disadvantages

R&D Investment

The biggest strength of OEM is also its biggest drawback. For quality R&D, you need heavy investments and high expertise. Since substantial funding, time, and effort are required for R&D, OEM involves substantial risk and difficulty.

Delayed Product Launch

Since the R&D process can be long and complex, quick product launches are hard, if not impossible. OEM often involves a long time-to-market.

Manufacturing Challenges

Unique product design may call for new tooling, assembly lines, and manufacturing equipment. Optimizing the manufacturing process for peak efficiency can take time.

Problems with Economies of Scale

Unless your product has high demand, achieving economies of scale will be difficult for the OEM factory you contracted.

Our next-gen manufacturing software is your answer to optimized processes.

Let’s Connect!Who is OEM Best For?

Bottom Line: The OEM model can work for you if you have high financial strength, exceptional technical expertise, and a willingness to take on high risk.

Original Design Manufacturing (ODM)

Original Design Manufacturing, or ODM, is concerned with white-label products and private labeling.

Under this model, the manufacturer owns the product design and offers it to the customer. If the customer accepts, the manufacturer makes the product in the customer’s name. That is, the product carries the customer’s brand name. It is simply a white-label product.

Car chargers are a good example of white-label products. When shopping for these on Amazon, you will note they are virtually identical despite different brand names.

That’s because they are white-label products – despite different branding, they are generic items with the same basic design from the same manufacturer.

Besides electronic items, ODM manufacturing is quite common for sports equipment, garments, and furniture. You can tell they are white-label products from their similar design.

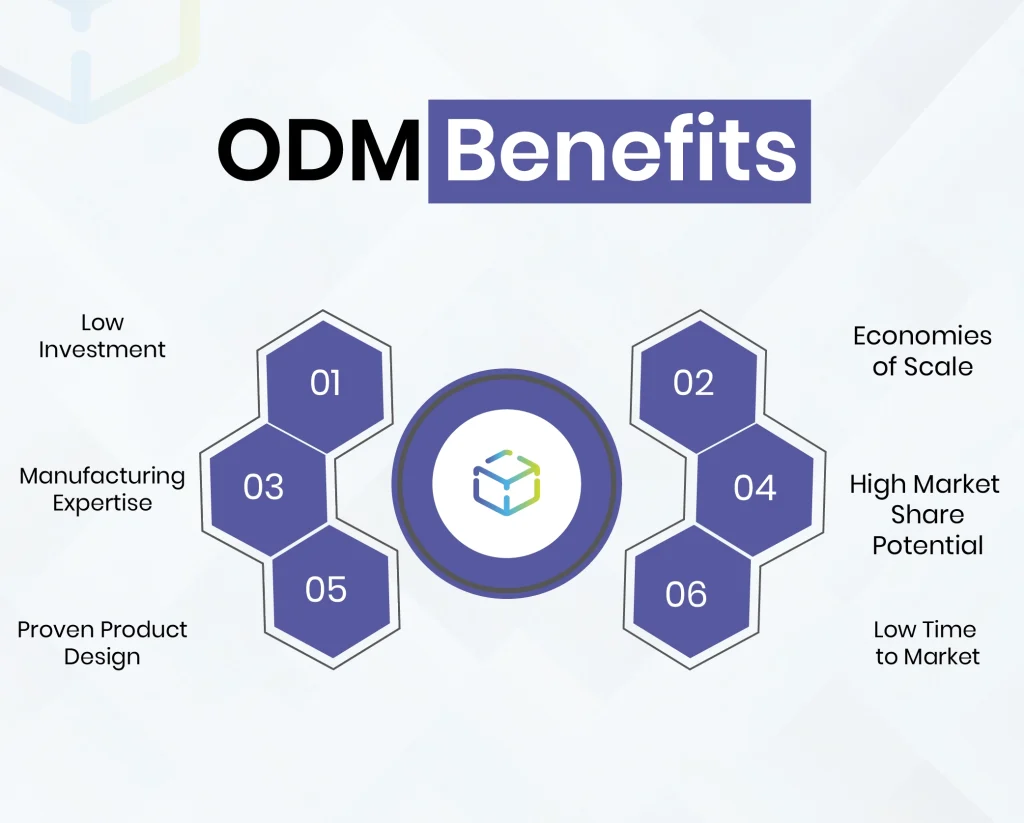

ODM Benefits

Low Investment

You don’t have to invest in R&D, since this is the responsibility of the ODM manufacturer. Since you need relatively little investment for ODM, the risk is lower than OEM.

Economies of Scale

Since an ODM manufacturer produces the same generic item for several brands, the production volume is often high, allowing for economies of scale. Mass production and subsequent economies of scale drive down unit costs.

Lower costs allow for competitive product pricing and high profit margins.

Manufacturing Expertise

ODM manufacturers have high technical expertise in mass production. They can thus streamline production and supply chain management for reduced product costs.

Brands that rely on ODM manufacturers can aggressively lower product prices and improve profitability thanks to low product costs.

Count on our proven manufacturing system to transform production.

Book FREE Demo!High Market Share Potential

As mentioned, brands can lower their prices with ODM manufacturers to gain a competitive advantage.

This matters because most consumers want the lowest prices on generic products that ODMs typically offer.

So ODMs are a good choice for selling generic items like car chargers.

Proven Product Design

Thanks to their experience, ODM manufacturers often offer reliable product designs that sell. These designs are often optimized through years of testing and customer feedback.

Hence, partnering with ODM manufacturers is a safe bet, since proven product designs carry less risk than new, untested designs.

Low Time to Market

Launching products is quick with ODM partners, since brands don’t need months or years of R&D to produce high-quality products.

ODM Disadvantages

Marketing Challenges

A major drawback is that since your products are generic, differentiating them is harder. Marketing requires much more creativity.

High Competition

You face stiff competition from rivals offering the same product as you.

Limited Customization

Product customization helps with cost reduction, improved quality, and innovation. Since you can’t change the product design with ODM, you lose the benefits of product customization.

Intellectual Property Rights

Lack of ownership over product design means less control over the product. The ODM manufacturer retains many important intellectual property rights.

High Dependence

Since brands don’t own the product design, they can’t simply shift product manufacturing to another factory if needed. Hence, brands have less power with ODM.

Who is ODM Best for?

Bottom Line: ODM works best for brands with limited funds.

Takeaway

Choosing between an OEM or ODM manufacturer comes down to financial strength and risk appetite.

You need high financial strength for heavy R&D investment in OEM manufacturing. Besides strong finances, if you are willing to take on the risk, then OEM manufacturing is the way to go.

But if you have less funds to spare and like to play it safe, then ODM manufacturing is the only realistic choice.