Most teams don’t need a reinvention; they need clean execution. This guide explains how receiving, slotting, picking, packing, and simple KPIs raise service while lowering cost. You’ll see what “good” looks like, where to tighten flow, and which quick wins compound fastest.

For context, e-commerce reached 16.3% of U.S. retail in Q2 2025 (seasonally adjusted), so throughput pressure is real in warehouse management.

You’ll also see where warehouse management software fits in the picture and when to consider it.

Table of Contents

What is Warehouse Management?

Warehouse management coordinates daily work so orders move from dock to door with minimal handling and zero ambiguity. It covers labor scheduling, slotting logic, replenishment rules, inventory status, and carrier dispatch.

A solid setup uses directed put-away, velocity-based pick faces, and event-driven cycle counts. Managers review dock-to-stock, pick accuracy, and order cycle time weekly, then fix bottlenecks at the process step—not by pushing harder.

Warehouse Management vs Inventory Management

People often mix up inventory management and warehouse management. Inventory management focuses on stock levels across the business and how much to buy or make. Warehouse management focuses on the physical handling, storage, and movement of items inside the four walls.

Knowing the difference helps you assign ownership and select systems. Inventory policies set what must be stored; warehouse practices determine how to store and ship it efficiently.

Map receiving-to-shipping, pick strategy, and replenishment logic. See concrete changes a right-sized WMS can standardize today.

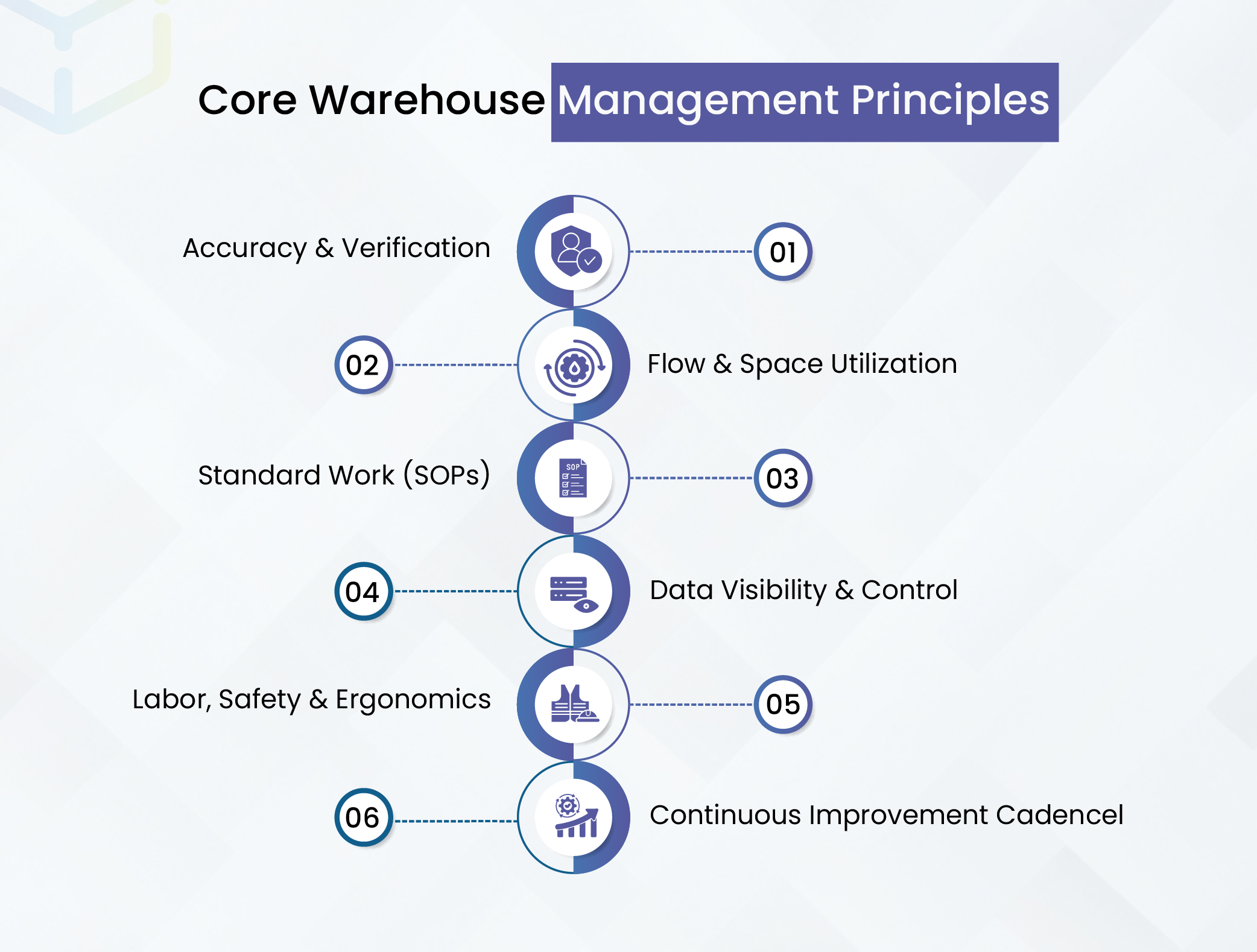

Optimize With WMSCore Warehouse Management Principles

These principles turn daily warehouse work into a predictable, low-error system. Focus on verification at every handoff, flow-oriented layout, standard work, trustworthy data, safe labor practices, and continuous improvement. Apply them consistently, measure weekly, and correct the process—not the person—whenever a variance appears.

Accuracy & Verification

Confirm item, quantity, condition, lot/serial, and location at each step. Use scan-to-confirm as the default. Treat undocumented moves as exceptions. Record damages immediately. Validate label quality. Accuracy at the source reduces rework, eliminates blind spots, and keeps downstream picking, packing, and billing on schedule.

Flow & Space Utilization

Design one-way travel from receiving to shipping. Separate forward pick from reserve storage. Slot fast movers near pack stations. Keep aisles clear and widths safe. Measure dock congestion and travel time. Better flow cuts touches, shortens lead times, and raises labor productivity without new equipment.

Standard Work (SOPs)

Document how to receive, put away, count, pick, pack, and load. Train to the SOPs, audit weekly, and update when data shows friction. Standard work prevents individual variants from becoming policy and makes quality measurable, coachable, and repeatable across shifts and new hires.

Data Visibility & Control

Maintain clean master data: units of measure, dimensions, handling classes, and statuses. Use stable location codes. Track item status (available, hold, QC, returns, consigned). Real-time visibility enables better task decisions, faster exception handling, and accurate promises to customers and internal stakeholders.

Labor, Safety & Ergonomics

Align headcount to waves and carrier cut-offs. Enforce PPE and equipment training. Keep heavy SKUs between mid-thigh and chest height. Mark pedestrian lanes. Audit near-misses. Reliable staffing and safe movement reduce injuries, overtime spikes, and unplanned downtime that disrupts fulfillment.

Continuous Improvement Cadence

Publish a short KPI deck—dock-to-stock, pick accuracy, order cycle time, OTIF. Review weekly, identify the step with friction, and run small trials. Lock gains into SOPs. This cadence encourages practical fixes, `prevents backsliding, and compounds throughput improvements over time.

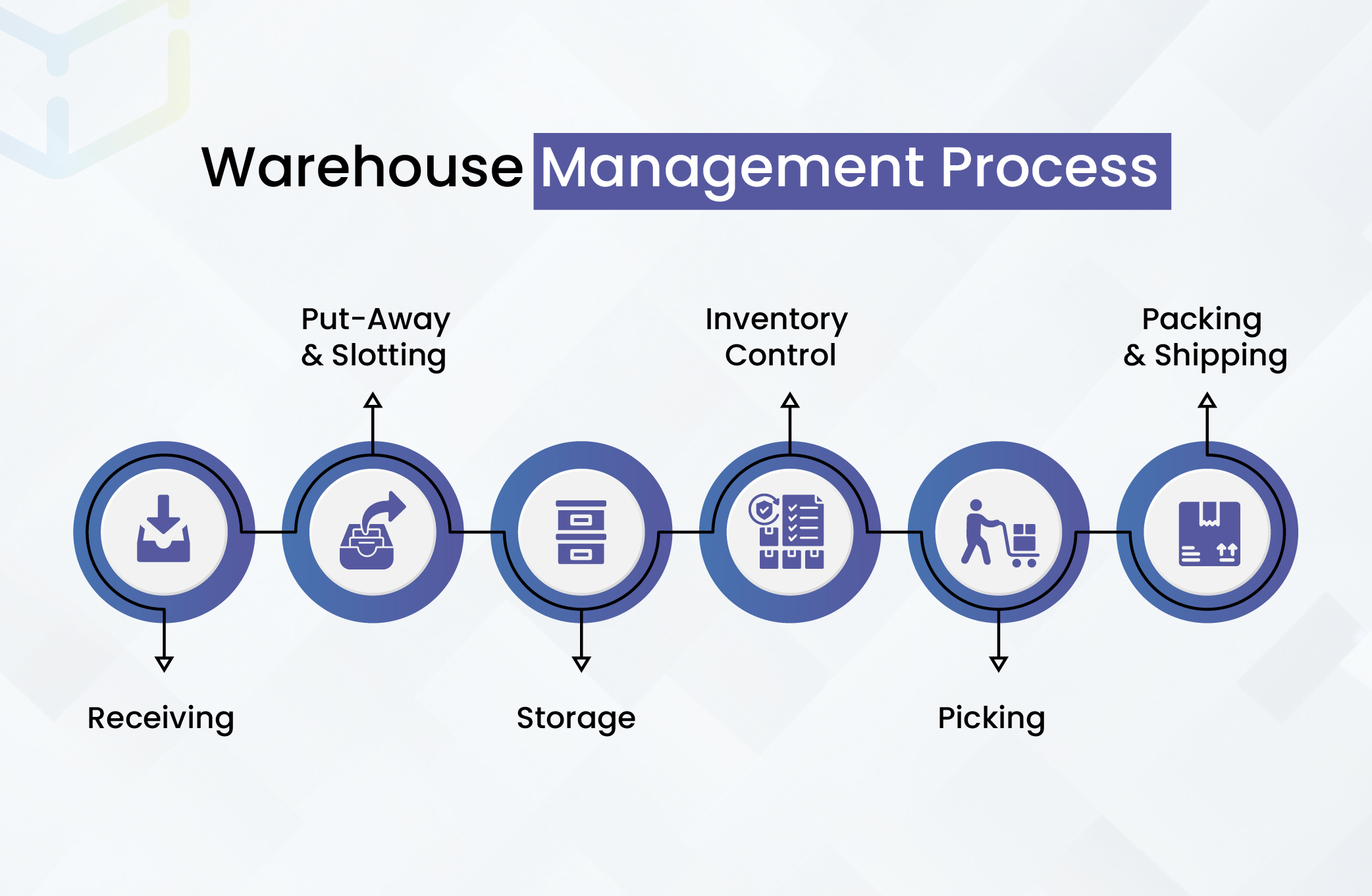

Warehouse Management Process

Most facilities run six linked steps: receiving, put-away and slotting, storage, inventory control, picking, and packing/shipping. Optimize each step, confirm with scans, and move exceptions to a visible queue. The goal: fewer touches, shorter travel, higher accuracy, and on-time handoff to carriers at the lowest total cost.

Receiving

Schedule dock appointments, use ASNs/EDI to prebuild receipts, and scan at the trailer. Verify counts and condition, record damages, and apply license plates or pallet IDs. Stage intelligently by destination. Fast, accurate receiving reduces dock congestion and makes inventory available sooner for picking.

Put-Away & Slotting

Use directed put-away with rules for velocity, size, weight, and handling class. Separate forward pick from reserve. Apply FIFO/FEFO for date-coded goods. Confirm location on arrival. Smart slotting shortens picker travel, improves replenishment timing, and increases cubic utilization without additional racking.

Storage

Maintain a stable location hierarchy (zone/aisle/bay/level/bin) and durable labels. Keep aisles clear, rack inspections current, and hazard signs visible. Store similar SKUs apart to prevent mis-picks. Clear, consistent storage makes cycle counts faster and prevents hunting for units during waves.

Inventory Control

Run ABC cycle counts—A daily, B weekly, C monthly—and event-driven counts after variances or damages. Track lots/serials where required. Separate hold/QC from available stock. Reconcile discrepancies within 24 hours and fix root causes. Tight control protects service levels and prevents emergency expedites.

Picking

Match strategy to order profile: discrete for simplicity, batch for common SKUs, zone to limit travel, wave for cut-offs. Use scan-to-confirm at pick, tote/cart organization, and visual cues for look-alike items. Picking discipline prevents chargebacks and keeps pack stations flowing.

Packing & Shipping

Verify contents by scan and, where useful, check-weight. Right-size packaging to reduce damage and freight cost. Print labels and documents from the system. Load trailers by stop sequence and carrier rules. Clean, predictable dispatch protects OTIF, reduces claims, and simplifies end-of-day reconciliation.

Get a quick assessment of flow, slotting, KPIs, and integration gaps. Learn where WMS lifts service and reduces cost.

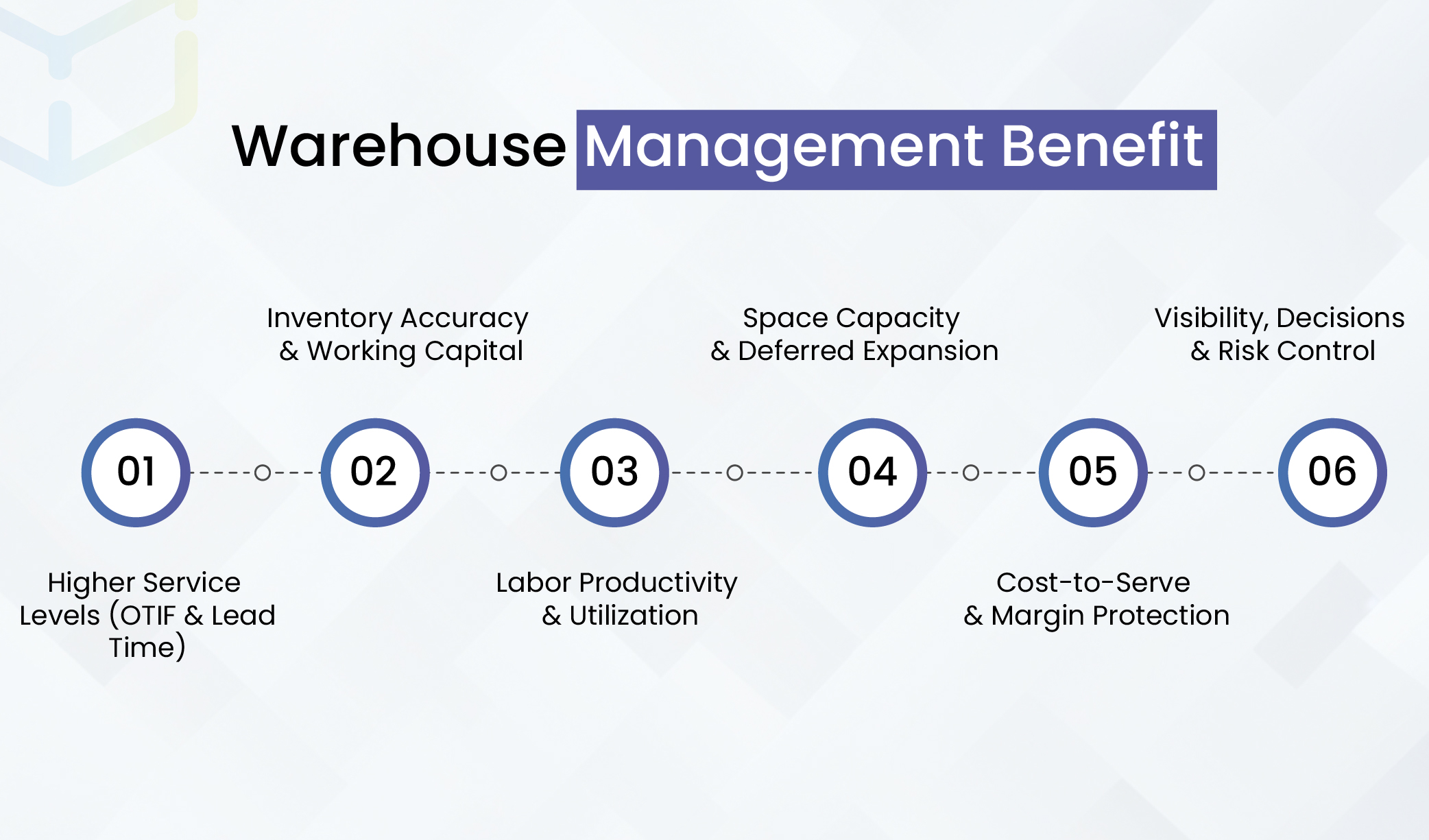

Consult WMS ExpertsWarehouse Management Benefits

A disciplined program raises service quality and reduces total cost without large capital outlays. Gains come from accurate data, shorter travel, fewer touches, and faster exception handling. The result: higher OTIF, lower labor variance, better space use, and clearer decisions that scale across shifts and seasonal peaks.

Higher Service Levels (OTIF & Lead Time)

Standard work, scan confirmations, and dependable cut-offs reduce rework and delays. Orders ship complete and on time, cycle times shrink, and customer promises hold during peaks. Consistent execution lowers chargebacks, improves carrier performance, and strengthens account relationships with concrete, repeatable reliability.

Inventory Accuracy & Working Capital

Location integrity, ABC cycle counts, and clean statuses keep system quantities aligned with reality. You buy less “just in case,” prevent stockouts caused by bad records, and reduce emergency expedites. Accurate on-hand data enables tighter reorder points and faster root-cause analysis when variances occur.

Labor Productivity & Utilization

Directed put-away, velocity-based slotting, and right-fit pick methods cut wasted travel and double-handling. Clear task prompts and balanced waves keep associates productive without overtime spikes. Supervisors spend less time firefighting, more time on coaching and incremental process improvements that sustain results.

Space Capacity & Deferred Expansion

Forward-pick design, replenishment rules, and slotting discipline unlock cubic capacity you already have. Fast movers sit close to pack; slow movers stay in reserve. Better space use delays racking projects or expansions and simplifies housekeeping, inspections, and safety compliance throughout the facility.

Cost-to-Serve & Margin Protection

Fewer touches, lower damage rates, and right-sized packaging reduce handling and freight cost per order. Accurate picks prevent returns and credits. Carrier compliance and planned dispatch windows avoid accessorial fees. Documented SOPs shorten new-hire ramp times and reduce training waste across shifts.

Visibility, Decisions & Risk Control

Unified tasks and statuses provide real-time insight into workload, exceptions, and capacity. Teams spot bottlenecks early and assign fixes to the exact step. Quality holds, recalls, and traceability improve. Safety audits and ergonomic standards reduce incidents, downtime, and regulatory exposure across operations.

Facility Design That Supports Flow

Good layout decisions cut travel, prevent congestion, and reduce handling without major capex. Prioritize a directional path from inbound to outbound, keep fast movers close to pack, separate reserve from forward pick, enforce clear markings and safe reaches, and place power/network where work happens so devices and scanners never become bottlenecks.

Zones & Direction

Map a one-way path: receiving → staging → reserve → forward pick → packing → shipping. Eliminate cross-traffic with physical barriers and signage. Keep staging near docks, pack near shipping. Directional flow shortens travel, reduces touches, and makes bottlenecks obvious during peaks.

Forward Pick vs. Reserve

Slot A-velocity SKUs in forward pick near pack stations. Keep B/C items and bulky pallets in reserve. Define replenishment triggers by min/max and time windows. This separation maintains short pick paths, smooths labor demand, and prevents last-minute scrambling when waves release.

Ergonomics & Safety

Set reach and lift limits, store heavy items between mid-thigh and chest height, and mark pedestrian lanes. Enforce PPE and equipment training. Audit near-misses weekly. Safer movement prevents injuries, stabilizes staffing, and protects throughput when volumes spike.

Utilities & Connectivity

Place power and reliable Wi-Fi at docks, pack stations, and charge bays. Standardize device cradles and spare batteries. Label printer locations for documents and carrier labels. Reliable connectivity and printing keep scan confirmations and dispatch timelines on track.

Fulfillment Strategies: Pick the Few That Fit

Choose pick and release methods that match order profiles, not trends. Start simple, measure results, and add complexity only when justified. The right combination reduces travel, stabilizes labor, and protects cut-off times without overhauling your building or buying equipment you don’t need.

Discrete Picking

One order at a time. Works well at low volumes or with varied SKUs. It’s easy to train, simple to supervise, and avoids complex consolidation. Use as a baseline; layer other methods when volumes concentrate around repeat SKUs.

Batch Picking

Group orders sharing SKUs to cut revisits to the same locations. Ideal for e-commerce with common items. Requires disciplined tote/cart organization and scan confirmations at pick and pack. Gains come from reduced travel, not rushing.

Zone Picking

Assign associates to zones. Orders pass through multiple zones or consolidate later. This limits travel, enables specialization, and supports parallel work. Pair with balanced waves to prevent idle time in slow zones and overloads in fast ones.

Wave Planning

Release work by carrier, dock door, time window, or priority. Waves align labor and equipment with shipment cut-offs. Keep waves short to expose problems early, and reserve capacity for late orders or rework.

Put-Wall Sorting

After clustered picks, sort items into wall cubbies by order. Great for many small, multi-line orders. Requires clear labeling, scan validation, and tight pack processes. Expect fewer touches at pack and faster cut-off compliance.

Cross-Dock

For pre-allocated inbound, move from receiving directly to shipping or forward pick. Bypass storage to save touches and time. Works when ASNs are reliable and appointments are tight. Protect with clear staging lanes and priority rules.

FIFO/FEFO Rules

Apply first-in-first-out for general goods and first-expired-first-out for date-coded products. Enforce at put-away, replenishment, and pick. These rules protect quality, reduce write-offs, and ensure compliance without adding manual checks everywhere.

Walk through inbound, slotting, picking, and carrier compliance in real time. Compare options against your data and constraints.

Book WMS DemoWarehouse Management Systems & Integrations

A WMS coordinates tasks, locations, and statuses in real time. It should guide receiving, directed put-away, picking, packing, shipping, cycle counting, and reporting—and exchange data with ERP, TMS, OMS, carriers, and EDI partners. Tight integrations remove rekeying, expose exceptions early, and keep promises accurate.

ERP Order & Inventory Sync

Import sales and purchase orders, push inventory movements and cost posts. Keep quantities, locations, and item masters aligned. This prevents allocation errors and avoids manual reconciliation at month-end.

TMS & Carrier Connectivity

Rate shop, select services, print compliant labels, and tender loads electronically. Share tracking back to ERP/OMS. Reliable links protect cut-offs, reduce accessorials, and simplify claims.

OMS Orchestration

Coordinate splits, backorders, and ship-from-location logic. OMS sends fulfillment decisions; WMS executes. This keeps promises realistic across DCs and stores, especially during promotions and peaks.

EDI/ASN & Document Flows

Use ASNs to prebuild receipts and verify quantities at the dock. Send confirmations (ship notices, invoices) back to trading partners. Standard documents reduce disputes and speed settlements.

Identifiers, Labels & IDs

Standardize GS1 barcodes, pallet/license plates, and location labels. Scan at each touch. Good identifiers make directed tasks reliable, reduce mis-routes, and simplify audits.

Reporting & KPIs

Publish a short, consistent dashboard: dock-to-stock, pick accuracy, order cycle time, OTIF, and space utilization. Tie each metric to an owner and weekly actions. Use exceptions queues to drive same-day fixes.

Wrap Up

Start with flow, accuracy, and clear roles. Slot fast movers near pack, separate reserve from forward pick, and keep scans and labels consistent. Pick strategies should match orders—not fashion. Use reliable, top-tier WMS to coordinate tasks and surface exceptions early. Small, disciplined changes compound into lower costs and better service.

If your current warehouse doesn’t have a dedicated WMS then consult today with WareGo for expert guidance.

Describe your order profile and constraints. We’ll outline a phased rollout, metrics, and expected conversion rate lift.

Talk To An ExpertQuick FAQs

Is warehouse management the same as inventory management?

No. Inventory management sets stock policies across the business and plans how much to buy or make. Warehouse management controls physical handling, storage, and shipping inside the facility. Clear separation improves ownership, reporting, and system design.

Which picking strategy should a beginner choose?

Start with discrete picking for simplicity and training speed. Add batch for repeated SKUs and zone to reduce travel as volumes grow. Apply FIFO or FEFO for goods with shelf life to protect quality and compliance.

What are the first metrics to track?

Begin with dock-to-stock, pick accuracy, and order cycle time. These expose delays at the dock, errors on the floor, and dispatch bottlenecks. Publish weekly, assign owners, and act on exceptions within 24 hours to prevent repeat issues.

How do I decide between wave and waveless release?

If you ship on strict carrier cut-offs with dock constraints, short waves add control and predictability. If orders arrive continuously and cycle times are tight, waveless release can keep work flowing. Pilot both and compare late-shipments, rework, and labor balance.

When should I separate forward pick from reserve?

As soon as fast movers dominate travel or picks queue at pack. Forward pick shortens paths and stabilizes labor. Reserve protects bulk storage and replenishment. Use min/max triggers and windowed replenishment to avoid pick-line stockouts during waves.