Your product range is a living system. Every new size, color, bundle, and channel SKU adds cost and complexity. SKU rationalization gives you a structured way to decide what stays, what changes, and what goes.

Using hard numbers and clear rules so you protect revenue while freeing cash, capacity, and focus. It is not a one-off cut. It is a repeatable review cycle that connects finance, operations, merchandising, and customer outcomes.

The fastest path to start is to bring truth together in one place. If your inventory management software already holds sales, returns, stock levels, and basic costs, you have everything you need to run the first pass and prove impact.

Table of Contents

What is SKU Rationalization?

SKU rationalization is a structured, repeatable review of every stock-keeping unit’s performance and purpose in your product portfolio. The goal is to remove underperformers and duplicates while protecting customer value.

It’s not the same as assortment planning, which asks what to introduce next; rationalization asks what should be simplified or retired based on evidence. It also connects front-of-house and back-of-house realities: what shoppers choose, what teams can pick accurately, and what it costs to carry.

Your warehouse management software becomes a quiet hero here, surfacing slow locations, error-prone variants, and storage footprints that don’t justify themselves. With those operational signals beside commercial results, decisions get clearer and far less political.

Have questions about your SKU rationalization process or scorecard setup? Get practical answers from a WMS and inventory pro in minutes.

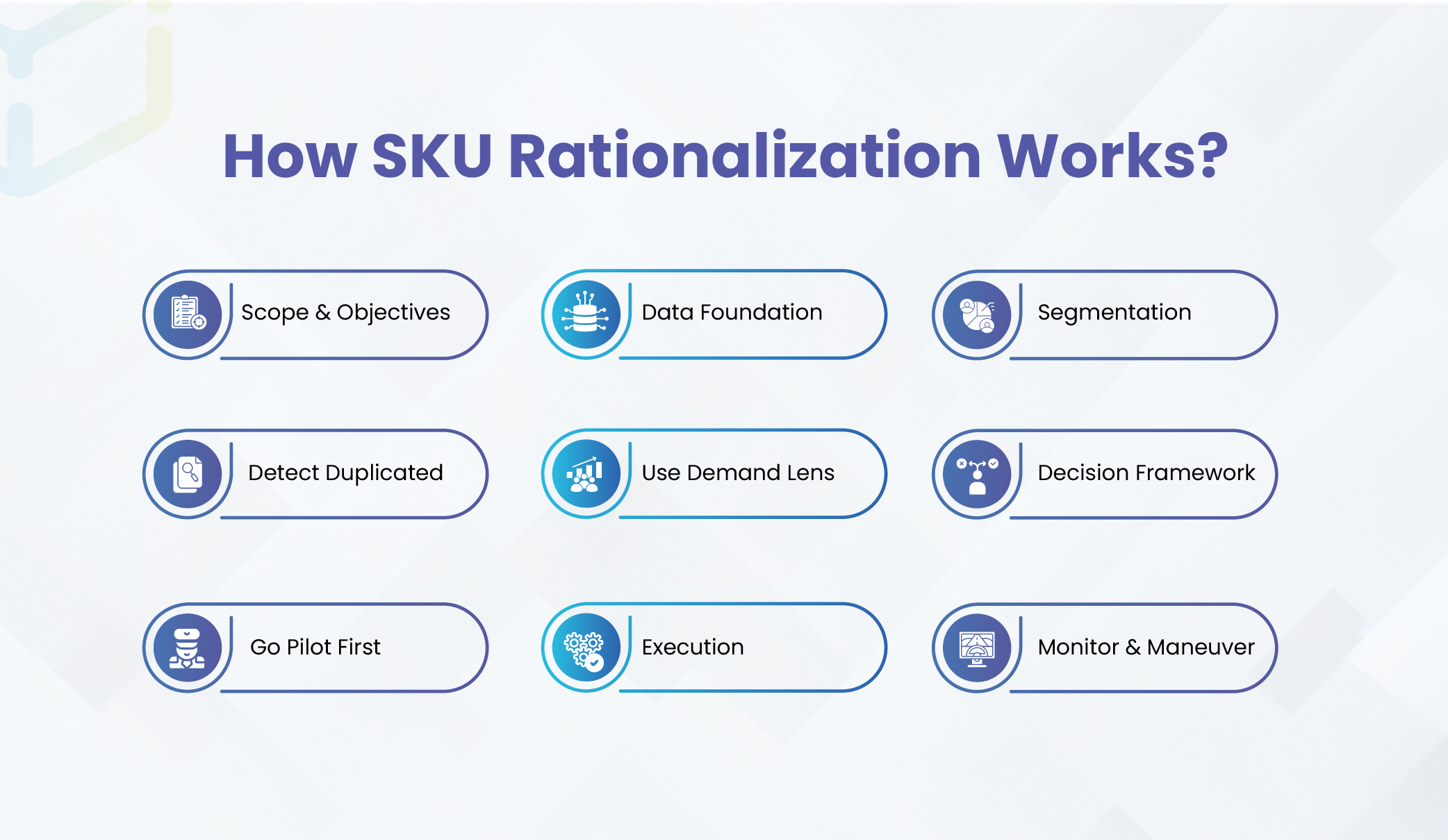

Chat with an ExpertStep-by-Step SKU Rationalization Process

After you understand what SKU rationalization is, it’s important to get into the nitty-gritties of the SKU optimization process. A step-by-step approach will help you map a clear path with actionable workflows and quality metrics. Here’s a complete SKU rationalization process:

Scope & Objectives

Pick a defined slice (one category, brand, or channel) and agree on the primary objective before you touch the data. Are you freeing cash, simplifying operations, or improving margin mix?

Clarity here decides the rules you’ll use later. It also sets guardrails: for example, accept a short-term mix shift but protect service levels and contracted SKUs. Treat this as a pilot with a 12-week horizon so teams lean in without fearing a big-bang cut.

Data Foundation

Bring together 12-18 months of clean history for the SKUs in scope: units and revenue after discounts, gross margin, returns with reasons, average stock on hand, and basic cost-to-serve signals such as storage, handling, and shipping.

Layer simple context like lifecycle stage, channels carried, and regional tags. If your item master is noisy (like if it has duplicate codes, missing attributes, mismatched kits) pause and fix it first. You’re building a decision engine; bad inputs ruin good intentions.

Segmentation Before Scoring

Split the set into sensible groups so you apply fair expectations. A-items carry the value; C-items are the long tail. Launches deserve patience; mature SKUs do not. Online-only items follow different dynamics than wholesale packs. This light segmentation stops you from retiring a winter hero just because you looked at a summer window.

Duplicate & Near-Duplicate Detection

Look for clusters of SKUs that are essentially the same choice in different packaging, sizes, or colours. If shoppers substitute freely between them or sales cannibalize across the group, you’re paying twice for one job. Rationalization here doesn’t remove the choice customers care about; it removes redundant options that hide your heroes and inflate handling errors.

Customer & Demand Lens

Not every “weak” SKU is dispensable. Some items, though modest alone, drive baskets, protect a price ladder, or keep a size run credible. Others peak in specific regions or seasons. Before you mark anything for sunset, check attach behavior, regional performance, and role in the set.

This is where category managers and demand planners earn their keep: they call out the items that hold the range together.

Decision Framework

Use insights to take clear actions. Keep and scale winners; improve borderline items with price, content, or packaging adjustments; limit thin sellers to the regions or seasons where they work; convert low-solo performers into bundles; and sunset SKUs that fail both commercially and strategically.

Use a simple scorecard to drive the default action, then permit documented overrides. The discipline isn’t the spreadsheet, it’s writing down why an exception exists and when it will be reviewed again.

Run a Pilot SKU Rationalization Implementation

Run the first wave in one category or region for at least one replenishment cycle. Announce what will change, how you’ll measure it, and the thresholds that trigger a rollback.

Watch service levels, order errors, and customer tickets weekly. Watch mix, sell-through, and cash released monthly. Pilots turn “we think” into “we know,” and they build trust for the broader rollout.

Execution & Change Management

Most value is won or lost in the handoff. Purchasing must stop buys for sunset items and reshape MOQs. Operations must re-slot shelves, collapse locations, and update pick paths. Ecommerce must refresh PDPs, map replacements, and redirect retired pages. Sales and support need talking points for customers and distributors.

Treat this like a release: one owner, one checklist, one source of truth, and a visible calendar.

Monitoring & Governance

Rationalization is not a spring-clean; it’s a habit. Hold a quarterly light review to stop drift and a deeper annual review before buying windows. Keep the rulebook public for what matters, how it’s calculated, and who decides. When people understand the game, they play on the same scoreboard.

See how warehouse management software surfaces slow movers, duplication, and space savings in real time. We’ll walk your data paths end to end.

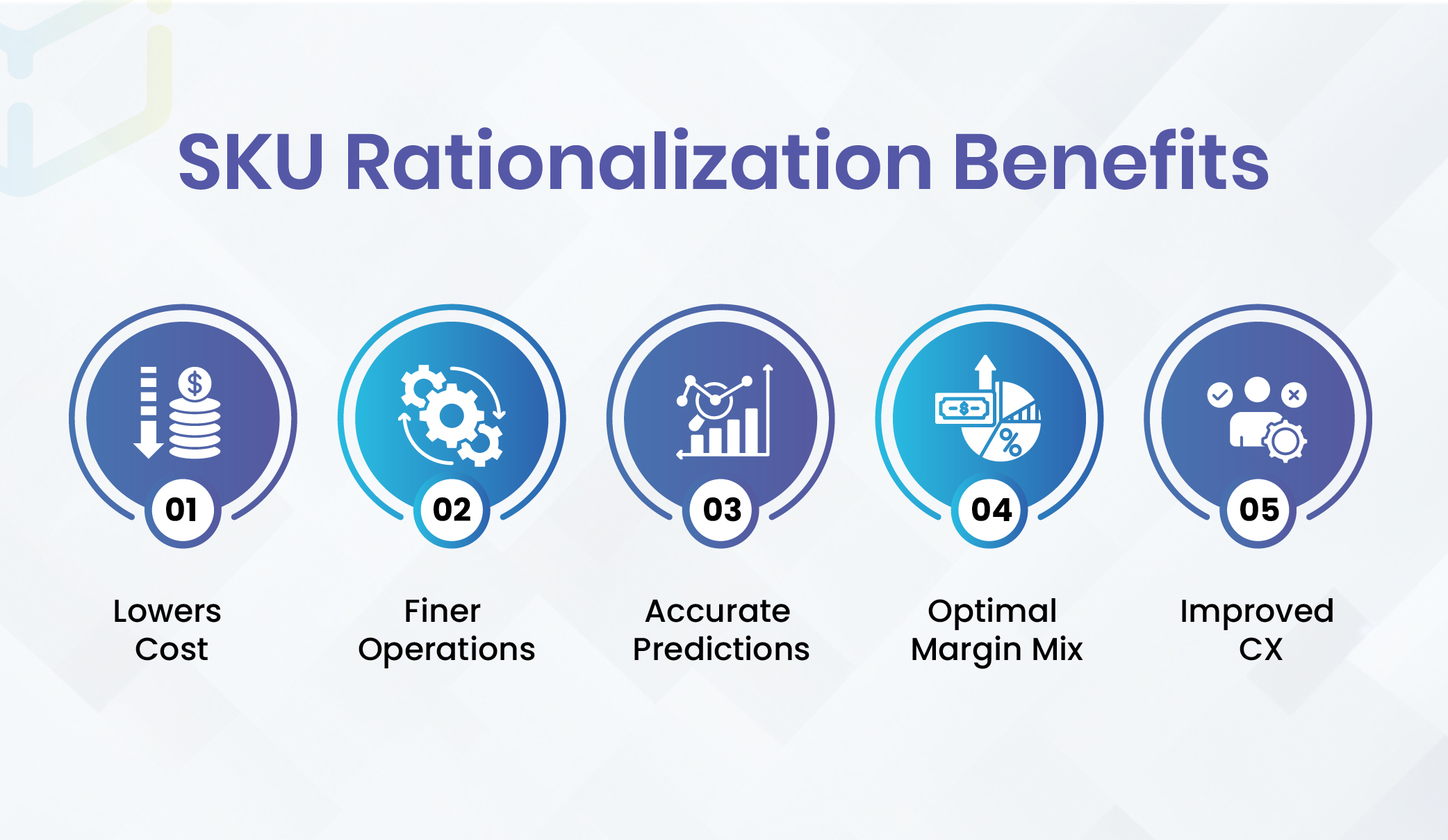

Book Live DemoSKU Rationalization Benefits

SKU rationalization trims slow movers and duplicates to lower carrying costs and release cash. Operations get simpler, availability rises, and errors fall. With a cleaner assortment, forecasts sharpen, cash turns faster, and margin mix improves without hurting customer choice.

Lower Carrying Costs Without Guesswork

You shrink the catalogue to what earns its place. That lowers storage fees, insurance, and write-offs, and it releases cash you can put into winners or working capital. Leaders feel this as fewer end-of-season scrambles and cleaner balance-sheet optics.

Smoother Operations & Fewer Mistakes

Every SKU you remove is one less location, label, and training edge case. Pickers see shorter paths and clearer bays; managers see fewer exceptions and a calmer floor. Accuracy climbs, and cycle times fall. Small changes in the set often unlock big changes in rhythm.

Sharper Forecasts & Replenishment

Noise drops when you stop splitting demand across near-duplicates. Planners get steadier signals, safety stocks shrink, and stockouts recede. Seasonality becomes easier to model because you’re not chasing five shadows of the same product.

Healthier Margin Mix

Marketing and trade spend can focus on products that return the favour. You stop propping up underperformers with constant promos and stop hiding great items behind clutter. Over a quarter or two, the mix shifts toward SKUs that carry more of the category’s profit.

Better Customer Experience

Shoppers find what they came for faster. The range still covers the need, but it reads clean. Fewer confusing choices, more inventory where it matters, and fewer disappointments at checkout. The brand looks decisive, not bloated.

Related Read: Best Inventory Management Tips

SKU Rationalization Best Practices

SKU rationalization best practices start with clean item masters, clear cost-to-serve, and a published scorecard with owners and review dates. Pilot one category, protect strategic or attach SKUs, and try to improve or bundle before sunset. Hold quarterly light reviews and an annual deep dive to keep the range honest.

Make the Item Master Boring & Right

You can’t optimize what you can’t name. Clean codes, complete attributes, clear relationships between variants and kits, and a simple lifecycle status keep the whole process honest. When a SKU is retired, every system should learn it once and reflect it everywhere.

Show Total Economics, Not Just Sales

Teams change behaviour when they see cost-to-serve beside revenue. A quiet, visual view of storage, handling, freight, and support per item reframes arguments and leads to better fixes—re-packing a product that gets hit by dim weight, or re-slotting a variant that causes mis-picks.

Use Rules, Then Allow Smart Exceptions

A published scorecard creates momentum; exceptions preserve sense. If you keep a thin seller, write why and when it will be revisited. That single discipline stops “pet SKUs” from creeping back without end.

Learn Before You Scale

Move one category or region, measure, and adjust. Pilots surface supplier constraints, marketplace quirks, and label issues long before they become rollout-wide headaches.

Bake Rationalization into New Product Introductions

Every launch should ship with a consolidation plan. If two items collide, decide early which one will survive and when. This protects teams from carrying duplicates for years because no one wanted to choose.

Want a steady hand on WMS and SKU optimization? Let’s talk.

Chat with WareGoSKU Rationalization Tools & Software

Here’s what you actually need to implement SKU rationalization for maximum impact and outcome.

ERP & Master Data as the Source of Truth

This is where items are born, cost, and retired. The more reliable your codes, attributes, and status changes, the less friction you’ll face downstream. Treat deactivation like a formal change: approvals, timestamps, and synchronisation to every consuming system.

Warehouse & Order Management for Ground Reality

Your operational layer shows which SKUs really hurt: the variants that trigger mis-picks, the bays that eat space, and the lines that never move. Use these signals to prioritise cuts and to quantify the capacity you’ll free. After each wave, re-slot the survivors so the benefits land in daily work.

Product Information & Commerce for Customer-Facing Clarity

When you reshape the range, customer content must keep up. Replace PDPs cleanly, redirect search traffic, and present clear “replaced by” options. A tidy catalog experience is part of the win; it prevents drop-offs when shoppers hit retired pages.

Planning & BI for the Decision Cockpit

Bring the handful of metrics into one view with simple flags for keep, improve, regionalize, bundle, or sunset. Add notes and owners so decisions don’t live in email. Refresh monthly; weekly is overkill for rationalization. This is the home for SKU rationalization metrics and the home base for your sku rationalization process reviews.

Assortment & Pricing as Levers, Not Crutches

Some teams jump straight to discounts when a SKU underperforms. Use price and promo as improved levers, not a permanent subsidy. Assortment tools help you set store or region-level ranges once you scale. Keep them transparent; black-box suggestions erode trust.

Choose Software Pragmatically

You don’t need a single “SKU rationalization platform.” You need a connected bench of systems across warehouse operations that expose reality and carry change. Start with what you own. Most teams can run the first two waves using existing analytics plus disciplined governance, then add SKU rationalization software or SKU rationalization tools only where the complexity truly demands it.

From slotting logic to pick paths, we deploy warehouse management software that supports your scorecard decisions at the floor level.

Scope My ImplementationSKU Rationalization in Practical World

SKU rationalization use cases cut across categories and channels: slimming bulky portfolios before seasonal buys, shortening pick paths in busy DCs, and right-sizing assortments for real demand. Teams apply it to retire low-yield items, deepen stock on proven winners, and align planning with cash goals to raise availability while freeing working capital.

Consumer Packaged Goods

Size and flavour creep is the norm. The fix is not to slash choice, but to retire redundant packs, regionalize niche variants, and push demand into sizes retailers will stock deeply. Factory changeovers drop, trade spend concentrates, and shoppers still find “their” product.

Apparel & Footwear

Full size runs sell the line, but dead sizes and duplicate colours drain cash. Rationalization tightens the palette, keeps the credible run where it matters, and bundles thin sellers with heroes to clear stock without training customers to wait for permanent discounts.

Electronics & Accessories

Models supersede quickly. Keeping an old version live confuses buyers and splits reviews. Rationalization sets crisp end-of-life rules, retires outdated SKUs, and clearly maps shoppers to the current fit, reducing returns and support tickets in one move.

Wholesale & Distribution

Customer-specific packs and legacy lines linger for years. Converting long-tail items to make-to-order and cleaning the public catalogue can release a surprising amount of space and capital, all while keeping contracted customers whole.

Marketplace Sellers & 3PL Ops

Duplicate listings and long-term storage fees are silent profit killers. Consolidating offer pages and pruning non-movers ahead of fee deadlines smooths cash flow and lifts Buy Box reliability. The warehouse breathes again because the tail stops expanding.

Related Read: Demand & Inventory Planning

Putting SKU Rationalization It Into Motion

Start small and make the rules visible. Choose one category, publish the objective and the guardrails, and gather the few signals that matter. Read them in context, not isolation, and assign one clear action per SKU.

Run a contained pilot, measure weekly operations and monthly commercial results, and share the learning in plain language. Then lock the playbook, repeat on the next category, and add only the tooling you actually need.

This evidence, action, and feedback loop turns SKU rationalization benefits from a slide into a habit. And once it becomes a habit, you won’t need a special project to keep the product range sharp; the range will keep itself honest.

Got SKU questions or a quick sanity check? Get direct guidance from a senior specialist now.

Start Live ChatSKU Rationalization FAQs

What is SKU rationalization?

SKU rationalization is a structured, evidence-based review of your catalog to decide whether each item should be kept, improved, regionalized, bundled, or sunset. It brings commercial results and operational reality into one conversation, so you trim slow movers, reduce duplication, and protect customer value. When the SKU rationalization process runs quarterly, teams see lower carrying costs, fewer picking errors, and a healthier margin mix—without forcing shoppers into fewer meaningful choices.

How often should we do SKU rationalization?

Run a light review every quarter to catch drift and a deep annual review before buying cycles. Quarterly reviews focus on outliers in sku rationalization metrics—items with rising days on hand, persistent stockouts, or creeping return rates. The annual pass resets thresholds by category, aligns with planning calendars, and codifies sku rationalization best practices for the next fiscal year.

Isn’t this just “assortment planning”?

They complement each other but solve different problems. Assortment planning looks forward—what to introduce for a season, store cluster, or channel. SKU rationalization looks backward—what to simplify or retire based on performance and role. Strong teams do both: plan the future set, then prune the past so the range stays sharp.

What metrics matter most?

Keep it simple and consistent. Read profitability (return on inventory and contribution after cost-to-serve), inventory efficiency (sell-through speed and days of inventory), demand quality (stability and seasonality), service (availability and fill rate), quality (return reasons), duplication (near-identical SKUs splitting demand), and attach value (basket lift). Together, those signals power practical SKU rationalization analysis without drowning the team in spreadsheets.

Which SKU rationalization tools do we need?

Start with what you have. Use BI to unify the few core sku rationalization metrics, your ERP as the item-master source of truth, and warehouse management software for ground-level signals like slotting, pick errors, and storage footprints. Add assortment tools when you manage many regions or store clusters. Most teams can run the first two waves with existing systems plus a clear scorecard—then layer specialized sku rationalization tools only where complexity demands it.

What is an example of SKU rationalization?

A beverage brand carried twelve nearly identical flavors in two pack sizes. Store-level data showed three flavors drove 78% of volume, while four flavors split the rest and created stockouts on winners. The team consolidated to six flavors, kept regional favorites in peak months, and bundled two thin sellers into variety packs. Within one quarter, days of inventory fell, shelf availability on winners improved, and promo dollars worked harder. That’s rationalization: fewer redundant choices, more depth where demand is real.

What is the SKU rationalization program?

It’s the governance and cadence behind the work: a published scorecard, category-specific thresholds, documented exceptions, and a quarterly/annual calendar. The “program” defines roles—category managers propose actions, finance validates economics, operations checks feasibility, ecommerce updates content, and leadership signs off. When everyone sees the same rules and dates, the process stops being political and starts being routine.

What does the term SKU mean?

SKU stands for Stock Keeping Unit—a unique, internal identifier for a specific product variant (such as a style, size, and color). It’s different from a universal barcode; the SKU is your company’s language for inventory. Clear SKUs and a clean item master are the foundation of credible SKU rationalization analysis and downstream SKU optimization.

What is the SKU rationalization rate?

It’s the share of SKUs in scope that change state during a wave—sunset, converted to bundles, or regionalized. Healthy ranges vary by category, but many organizations see 10–20% action in a first pass, then a steadier 3–8% per quarter. The rate matters less than outcomes: faster sell-through, fewer errors, and better contribution after cost-to-serve.

What is the best software for SKU rationalization?

There isn’t a single “best” app; there’s a best stack for your size and channels. Start with BI to assemble a decision cockpit, ERP for item master governance, and warehouse management software to surface slow locations, error-prone variants, and storage impact. If you need deeper range decisions by region or banner, add assortment optimization. If you’re on WareGo, pair our modern WMS with an inventory analytics layer and the item-master cleanup checklist; that trio covers 90% of practical sku rationalization software needs without lock-in.

How does SKU optimization differ from SKU rationalization?

Think of SKU optimization as the broader discipline: shaping the range to maximize customer value, margin, and operational flow. SKU rationalization is a key tactic inside it—pruning underperformers and duplicates so the catalog stays focused. Optimization also includes price ladders, pack architecture, and cross-sell design; rationalization makes space for those changes to work.