Worried about frequent stockouts and overstocking? PAR or Periodic Automatic Replacement can reduce the risk of these inventory problems.

But what is a PAR level? It is the right amount of inventory to fulfill demand without excess stock. Warehouse management software not only gives you a precise PAR level for all items, but it also enables you to automatically replenish them. Hence, you don’t face stockouts.

Several industries rely on PAR calculations to efficiently control perishable goods. Hence, pharmaceutical and hospitality businesses, among many other industries, calculate the stock volume they need to prevent this stock from running out before the next stock purchase. They do so using inventory management software since it maintains detailed stock information that shows you the precise PAR level for each SKU.

Will WareGo work for your business? Find out with a COMPLETELY FREE trial.

Start My FREE Trial!We will show you what PAR is, why it matters, and how it’s determined. This can become a key part of your inventory management toolkit.

Table of Contents

What Is a Par Level Inventory?

What is a PAR level inventory?

PAR level refers to an inventory control method that shows how much stock you currently need to fulfill demand without stockouts.

Hence, PAR determines the optimal inventory amount you need after stock shipping. Do note that PAR levels can be variable since they depend on seasons, trends, events, and other such factors that influence consumer demand.

This matters in particular for industries that must deal with perishable stock. Hence, PAR level calculations are used extensively across pharmaceutical, healthcare, hospitality, food and beverage, and other such industries.

For example, in the restaurant business, preventing food expiry and waste is paramount for high profitability. Hence, the PAR level informs restaurant owners about the stock they need on hand to fulfill customer demand without running into excess supplies that could result in expiration, waste, and restricted cash flow.

What Is a Par Level Stock?

Business owners and managers should know: What is a PAR level stock?

With this knowledge, they can be confident about having enough stock in their disposal to meet customer orders without waste and unsold goods.

The optimal order quantity for an item is the amount needed for the current stock level of this item to hit the PAR level. Hence, such calculations can guide inventory planning and purchases.

For instance, suppose that the PAR level for pickle jars stands at 16, but you have just 9. This means that you need to order seven more pickle jars. Hence, a simple PAR calculation can show you how much to order from your supplier.

How PAR Levels Benefit Inventory Management

Determining the PAR level can boost your inventory management performance in the following ways.

- Reduces wastage in perishable goods

- Minimizes stockouts and overstocking

- Improves inventory turnover rate

- Enhances inventory ordering

- Ensures your stock order is set at the right level

Should Inventory Exceed the PAR Level?

For specific industries, having inventory levels at the PAR level may sometimes be justified. Many businesses go through seasonal demand fluctuations. Plus, there are special events and holidays during which demand exceeds usual levels.

For instance, in the hospitality sector, it is better to keep stock levels above PAR levels when demand is unusually high. This can happen due to certain seasons and events when the demand for food and beverages goes higher than usual.

This could be the weekend, for instance, when people are just in the mood to go out for food. Wedding seasons and holidays also lead to sudden spikes in demand for which stock should be above the PAR level.

There may be shipping delays or delivery problems at specific time periods, due to which your stock may exceed the PAR level. Holidays and even supply chain disruptions may result in such shipping and delivery issues.

Differences Between a Reorder Point and the PAR Level

The PAR level method replenishes stock levels by enabling you to order the stock amount that will bring your stock back to the PAR level.

The reorder point method is slightly different because it orders the stock amount that will mitigate stockout risk as well as shipping delays.

Both systems are similar in that they try to minimize the stock level you maintain in your warehouses. However, they also aim to maintain inventory so that your business does not run out of stock.

To maintain this balance, it is important to order stock at the right time.

The following detailed descriptions will outline the key differences between the two approaches.

PAR Level Method: Under this inventory management system, action should be taken when inventory falls below a certain amount. Besides fulfilling current demand, the PAR level aims to satisfy sudden spikes in demand. As soon as inventory goes below the PAR level, there should be an order for more inventory to restore stock to the PAR level.

Reorder Point Method: product lead time is factored in to understand when to reorder after stock falls below a specific minimum amount. The reorder point method tries to minimize the risk of lost sales. Hence, the reorder point may depend on peak demand season, supply chain disruptions, or delayed shipping. Reorder points are usually better for the retail sector since these businesses can often afford to pay for higher inventory levels.

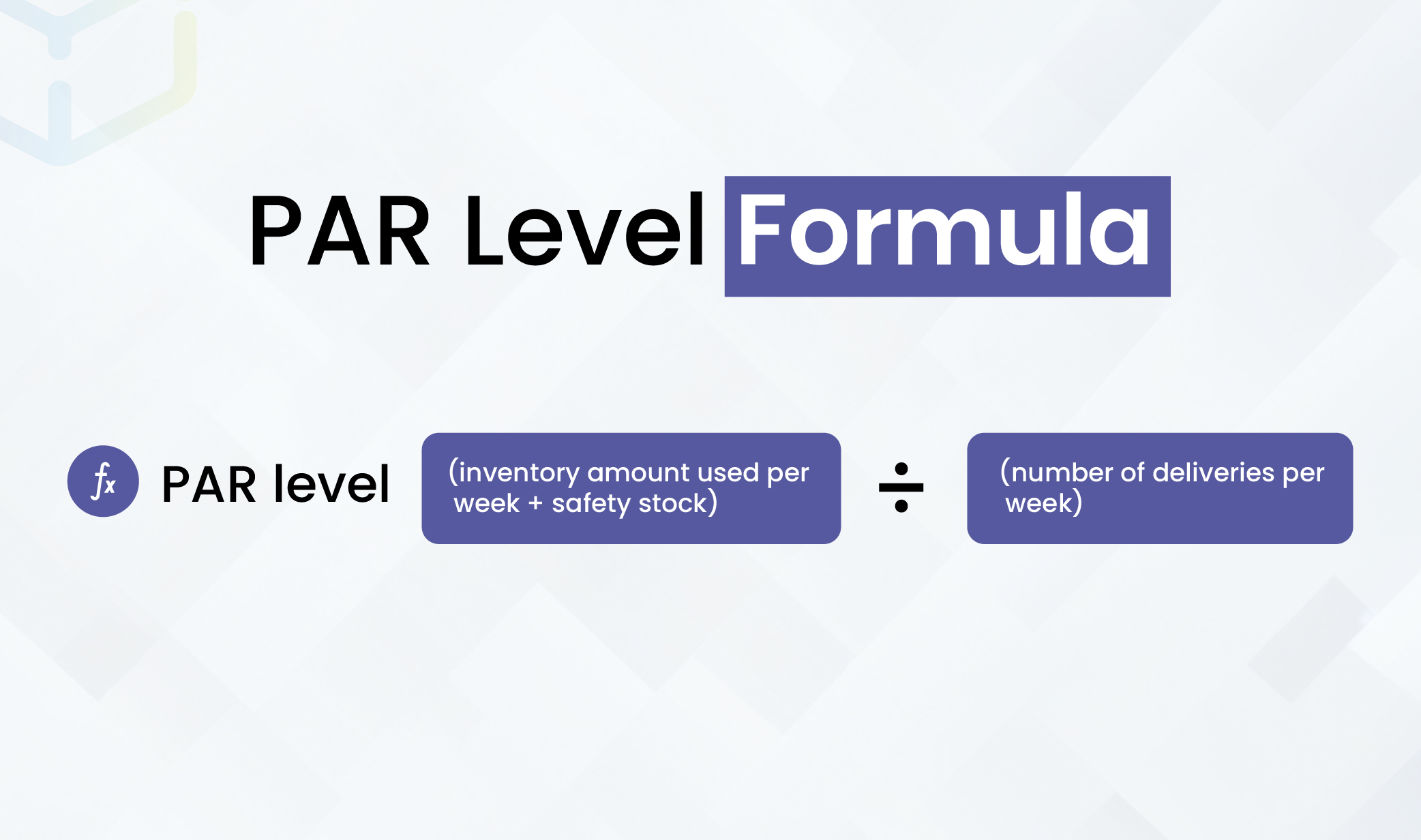

PAR Level Formula

You can calculate the optimal inventory amount with the following PAR level formula:

PAR level = (inventory amount used per week + safety stock) ÷ (number of deliveries per week)

Hence, establishing the PAR level requires understanding how quickly your inventory sells each week and also knowing how many deliveries are made per week.

You then find out the PAR level using this information as follows.

- Go through historical demand patterns for your inventory to find out how much stock is being consumed per week on average.

- Safety stock must be included to offset sudden spikes in demand. The best practice among restaurants is to keep safety stock at about 25 percent of weekly consumption.

- Note the delivery frequency of the product per week.

Various industries may use somewhat similar formulas for calculating the PAR level. However, there is a key difference. The safety stock level may be different for each item.

The 25% safety stock rule is a relatively safe and simple way to plan for unexpected surges in demand. However, it would be better to look into your inventory turnover rate and review sales reports to avoid excess stock levels and subsequent waste, plus storage costs.

PAR Level Calculator – An Example

When determining the PAR level, you should first take into account how many times the item is delivered in a given time frame. Perishable items such as fresh milk and bread may have daily deliveries. But other products, such as flour and butter, may have weekly deliveries.

After doing this, find out from the PAR level calculator how much of the item is consumed between deliveries.

For instance:

Suppose your restaurant provides 200 servings of chips each week. One bag of frozen chips gives 10 servings of chips. Hence, you need 20 bags of frozen chips per week for your restaurant.

In addition, you also need to keep safety stock at hand to cover potential problems like demand spikes and waste. Assuming a safety stock rate of 20%, you should thus have four bags of frozen chips as a reserve.

Further, suppose that your supplier ships on Mondays. That is, once per week.

Hence, the PAR level for bags of frozen chips would be:

20 bags + 4 bags = 24 bags

Our friendly experts can explain how WareGo can bring great value to your business.

Start My FREE Consultation!Industries that Require PAR levels

Various methods of PAR level calculations are frequently utilized by the hospitality sector, in particular, food and beverage businesses.

Other industries, such as pharmaceuticals and healthcare, also make extensive use of PAR level inventory, including hospitals.

The healthcare sector uses the PAR level method to prevent sudden shortages in pharmaceutical drugs. It also covers problems like expiry and theft, which can create sudden stockouts.

PAR level inventory not only avoids overstocking and high associated costs for the healthcare sector, but it also ensures the steady flow of critical items like PPEs (personal protective equipment). Hence, healthcare operations can proceed smoothly without disruptions.

What Is a Par Level in Pharmacy?

Pharmacies rely on the PAR level inventory method to ensure an adequate supply of pharmaceutical products and to cover issues like limited shelf life.

For example, certain medications and vaccines have short expiry dates and need to be kept in cold storage. Many pharmacies have limited cold storage space, due to which PAR level inventory is necessary.

Pharmacies and chemist stores must also stock items with strong seasonal demand, like flu tablets for the winter and sun protection items for the summer season. In this case, the PAR level method needs some adjustment to factor in the sudden spikes in seasonal demand.

What is the PAR level in Hospital?

Hospital procurement staff rely on the PAR level inventory method to replenish healthcare items in the right amount at the right time. They have to balance between overstocking and understocking with the PAR level in hospital. Overstocking can tie up limited funds and incur extra storage costs. Understocking greatly increases the risk of stockouts, which can create disruptions in hospital service.

Hospital inventory management is further complicated by challenges like maintaining the right combination of medications and following related protocols. Hence, the PAR level method ensures high availability of medicines and their optimal management to minimize expiry.

The same management techniques can be extended to items like linens and towels to ensure adequate supplies for patients and the elderly under care.

For instance, suppose a hospital has 80 beds. For each bed, two bed sheets are required each day. Also, a safety stock level of 25% needs to be maintained to cover extra use, plus, there are two deliveries per week.

The PAR level formula in this case will be:

PAR level = (inventory quantity consumed per week + safety stock) ÷ (weekly deliveries)

The PAR level for sheets turns out to be:

(1120 bed sheets + 280 safety stock) ÷ (2 weekly deliveries)

= 1400 bed sheets

When placing a delivery order, you will have to deduct the total stock at hand from the 1400 bed sheets. This is the optimal amount that needs to be ordered.

What Is a Par Level in Healthcare

What is a par level in healthcare?

It is the number of items you need to keep at hand so that you don’t run out of these products before the next supply delivery.

Surgical equipment and pharmaceuticals are certain critical items with high inventory turnover in the healthcare industry.

Given the sensitive nature of healthcare operations, it is necessary to have adequate stock at hand to meet sudden spikes in demand. Hence, hospitals must deal with inventory that includes MRO items, disinfectants, cleaners, bandages, syringes, and PPEs. The PAR level method may be extended to these items as well as part of the healthcare inventory management.

Book your free demo now. See our cutting-edge platform live in action.

Start My FREE Demo!How the Hospitality Sector Used the PAR Level Method

Cafes, bars, restaurants, and other hospitality-based businesses deal in perishable goods that can undergo waste if not managed properly. This is another example where the PAR level inventory method improves the management of sensitive goods.

To understand the PAR level for any product, first take a look at the historical inventory data. This will reveal how much stock is consumed each week on average. You can then factor in the safety stock to handle demand surges and shipping delays.

For instance, suppose the weekly potato use is 20 kg for a restaurant. Factoring in a 25% safety stock level, the PAR level is 25 kg for potatoes. Hence, when placing an order, the restaurant should request an amount that will take the current stock to 25 kgs.

However, the PAR level may be subject to adjustment based on factors like changes in seasons. Besides seasonal demand variations, other factors may have to be considered, like changes in menu items that require potatoes. Price changes may also impact the potato PAR level.

PAR Level Benefits

Maintaining accurate records for inventory is important for understanding how much of an item to order and at what frequency. The PAR level method can enhance inventory management by minimizing stockout and overstocking risk.

Here are other key advantages of the PAR level inventory method.

Less Waste

In the hospitality business, food costs comprise around a third of total costs. Wastage is a big part of food costs. For most businesses, on average, around 10% of the food goes to waste instead of generating revenue. This represents extra costs and lost sales. PAR level inventory can minimize wasted food.

Better Supply Management

The PAR level technique is ideally suited for better supply management because it enables you to order the right amount at the right time.

Enhanced Cash Flow

As explained, the PAR level method reduces wasted food, which saves money. Also, for other types of inventory, the PAR level method allows you to maintain optimal levels without overstocking, which unnecessarily ties up large amounts of cash, besides incurring higher holding costs.

Improved Customer Satisfaction

Since the PAR level method minimizes stockout risk, customer demand is fulfilled regularly, which improves customer satisfaction. This matters since customers are unlikely to return to a business that experiences frequent stockouts.

Higher Profitability

Reducing the risk of overstocking and understocking both result in higher profits. By preventing understocking, there are fewer lost sales. Preventing overstocking reduces high holding costs. Hence, profit margins improve with the PAR level technique.

Reordering Stock with the PAR Level Method

You should note that the calculated PAR level is NOT the amount to order. From this calculated PAR level, you should deduct the current inventory volume. This resultant figure is the amount to order.

A simple way to understand this is to recognize the PAR level as the baseline for your inventory. When inventory falls below this baseline, you must order enough items to bring inventory back to this baseline.

Going back to the potato example, suppose the PAR level of potatoes for a restaurant is 25 kgs per week. If the stock falls to 5 kg at the end of the week, you must order 20 kg of potatoes, not 25 kg.

Of course, if your inventory goes down to zero, you will have to order an amount equal to the PAR level. But in this case, you should reconsider the safety stock percentage and bump it up a bit if stockouts start rising.

Managing PAR Level – How it’s Done

There are two main ways of managing PAR levels.

Spreadsheets

This is the easiest way to start managing inventory. However, it has several drawbacks, especially if you have many SKUs. Spreadsheets can quickly become chaotic as more and more items need to be tracked. You must also be adept at Visual Basic or Python programming languages if you want to automate Excel tasks. If you don’t, you will have to spend hours each week to handle manual work.

Inventory Management Software

The best method by far for serious businesses to manage their inventory. The system can keep accurate records of your inventory items and give you real-time visibility for each SKU.

PAR level management is a cinch with a robust inventory system. The software can order stock automatically when it goes below critical levels. It also automatically issues alerts and notifications for low stock.

In addition, it automatically updates stock levels with each transaction thanks to built-in support for barcode/RFID scanning and POS terminals.

Managing suppliers is also much easier due to 3PL support that allows strong coordination with your supply partners.

For managing perishable items and reducing expired goods, you absolutely do need inventory software that supports FEFO (first expired, first out).

You can gain all of these much-needed benefits from WareGo – the best inventory solution by far.

WareGo – Your Go-to Inventory Platform

Besides providing all aforementioned benefits, WareGo inventory also gives you the power of the cloud. With just a browser and an internet connection, you can access WareGo anywhere on earth. There is no need to deploy the software on your premises. This truly matters since you are saved from the technical difficulties of many kinds. You are free to use the software, while the vendor takes care of maintenance, upgrades, troubleshooting, and other technicalities.

The software also integrates with popular business systems, including ERPs, CRMs, accounts, ecommerce platforms, and more. Thanks to these integrations and comprehensive automation functions, you can avoid manual data entry and subsequent errors and delays. Your inventory works for you, not the other way round.

AI-powered forecasts analyze previous demand patterns to accurately predict optimal inventory levels for all seasons. Plus, you get plenty of valuable insights via analytics and reports to boost profits.

Find the most competitive rates in our fully transparent and simple price plans.

Check price plans!FAQs

What does par level stand for?

PAR level is the short form of “Periodic Automatic Replenishment” level. It is the amount of inventory the business should have when it restocks.

What is a par level in medication?

This is the target level for the inventory item following stock replenishment. Think of it as the maximum amount a hospital, clinic, or pharmacy should have for items like medications, surgical equipment, and other medical supplies.

How do you calculate par level?

The simplest method for calculating PAR level is as follows:

PAR level = (Average Weekly Usage + Safety Stock) / (Deliveries per week)

What is an example of a par level system?

A restaurant can provide a simple example of the PAR level system. Suppose 30 packs of butter are needed by the restaurant each week. If at the end of the week, 12 packs of butter are left, the restaurant must order 30 – 12 = 18 packs of butter.