Inventory is one of the key assets for any kind of business. Mastering inventory management is vital for making your business profitable. However, this is easier said than done because it entails several complexities and nuances. Hence, you should know about 10 inventory management techniques, why they matter, and which ones you should implement to drive success.

In general, streamlining inventory control helps you to minimize inventory costs, which can be substantial. By maintaining optimal stock levels, or lean inventory, you can free up plenty of cash without running a high risk of stockouts.

This comprehensive guide lays out the basics of 10 inventory techniques that can potentially enhance your operational efficiency. This way, your inventory asset will work for you, not against you.

We will also show you how technology can help you implement state-of-the-art inventory management that will provide exceptional value for your business.

Table of Contents

Techniques of Inventory Management – the Basics

Inventory management techniques and tools involve controlling and tracking the movement of various goods, including finished items, work-in-progress, raw materials, and consumables, at all stages of your business operations, from receiving purchases to shipping merchandise, and everything in between.

Well-executed inventory management helps a business keep the right stock in the right place and in the right amount. This way, the business fulfills customer demand as quickly as possible while keeping inventory costs—such as storage, shipping, and wastage—low.

When done right, the techniques of inventory management can greatly reduce stockout risk, where you don’t have enough stock at hand to satisfy customer demand. You lose sales due to stockouts and your valuable customers as well.

Inventory management done right also helps reduce the risk of overstocking, which cuts into profits due to unsold stock, high storage costs, and waste. You end up investing extra cash to maintain excessively high stock levels. This restricts your cash flow, making it harder to execute required operations.

Additionally, effective inventory management enables a business to manage seasonal demand and sudden spikes in customer demand. It keeps your supply chain agile, making your business more resilient to logistics challenges and disruptions. These benefits and more are all possible if you implement techniques for lean inventory management.

To implement rock-solid inventory management, you need an all-in-one WMS that gives you all the tools necessary to track, allocate, automate, and forecast inventory. Any business that is serious about staying highly competitive via efficient inventory management just can’t do without a good WMS. In short, a state-of-the-art WMS suite is not an option – it is absolutely indispensable for you to survive and thrive in the increasingly competitive business realm.

Key Takeaways

- Inventory management lets you keep just enough stock to satisfy demand. Excess stock is minimized to reduce high carrying costs.

- Several inventory methods exist, like ABC classification, just-in-time (JIT), and dropshipping.

- Modern technology, like barcode/RFID scanning, AI-powered forecasts, and WMS solutions, is vital for good inventory management.

- With advanced inventory methods, businesses can streamline inventory for a more agile supply chain.

Why Inventory Management Techniques Matter

Efficient inventory management reduces costs, boosts productivity, and speeds up operations. It can prevent:

- Stockouts: running out of stock leads to lost sales

- Overstocking: With excess stock, you lose money to unsold goods.

Good inventory management raises profit margins.

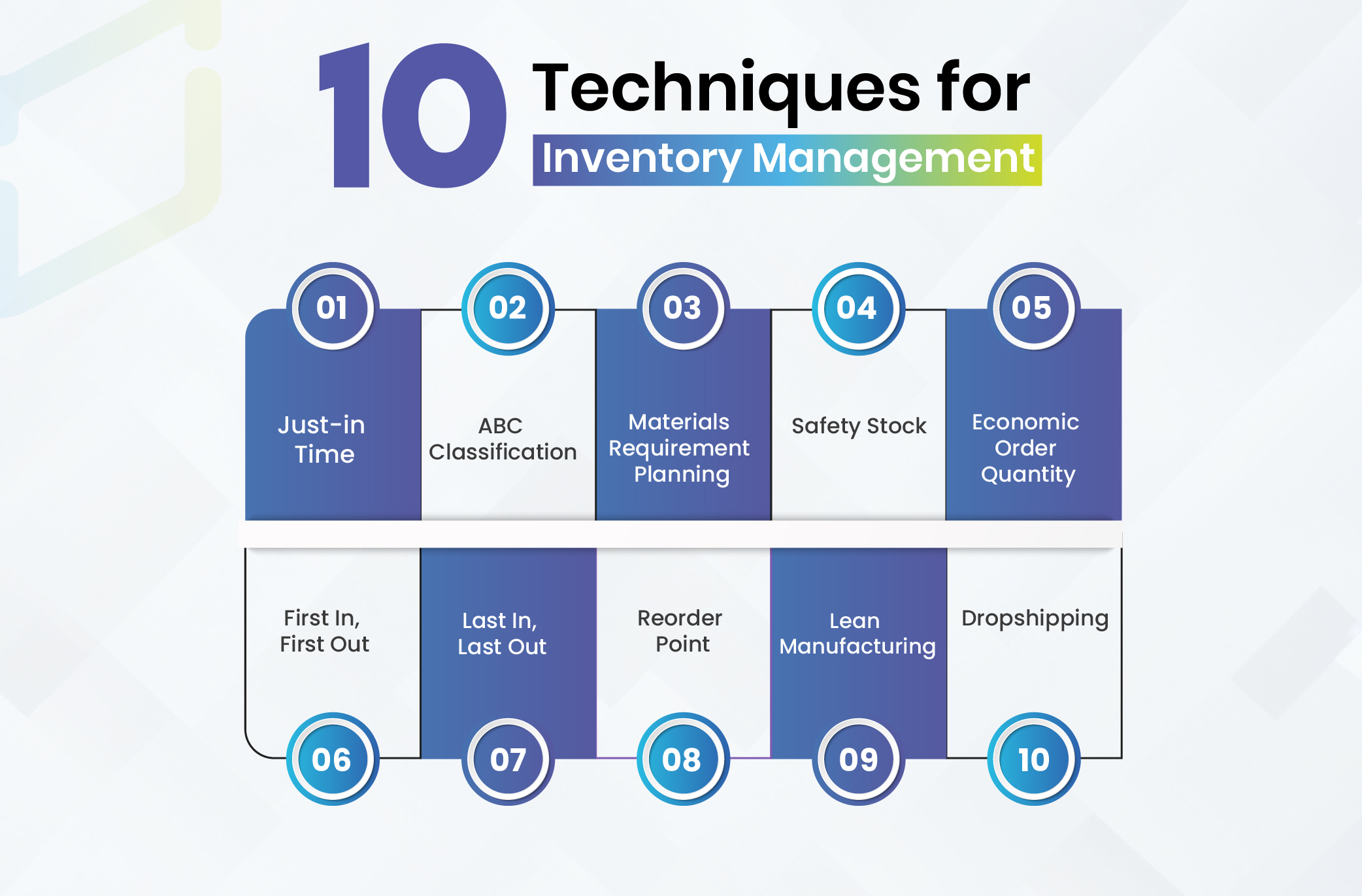

10 Techniques for Inventory Management

There are several ways to manage inventory. The method you choose depends on the nature of your business.

Before going any further, it is also worth noting that a good WMS can be a game-changer for inventory management performance. Hence, we will be showing how exactly a capable WMS can help with various inventory methods.

Here are some of the most commonly used techniques for inventory management you should be aware of.

1. Just-in-Time

As the name suggests, this method arranges for inventory purchases to arrive exactly on time – when you need them, and not before that.

Manufacturing companies commonly use this inventory control technique. They schedule purchases and time deliveries so inventory arrives exactly when needed for production, but not earlier.

It is clear that this method helps reduce waste while enhancing operational efficiency.

In order to maintain high quality with JIT, you need to enter into long-term agreements with the most dependable suppliers who are known to deliver on time.

People also call JIT lean management. This technique comes from the Japanese Kaizen philosophy, which focuses on small incremental improvements that lead to faster operations and better product quality. The philosophy stresses continuous improvement. Everyone, from factory floor workers to the CEO, contributes ideas for small improvements to boost product quality, cut waste, and streamline operations.

Although it seems simple in theory, there are certain challenges to JIT implementation. Demand forecasts must be highly accurate. This can be difficult if demand fluctuates. Also, JIT implementation can be challenging for complex supply chains that involve the movement of many different types of goods. A good example of this is the highly complex automotive supply chain, which must ensure the timely delivery of thousands of components.

A powerful WMS solution will give you all the tools you need for maintaining just-in-time inventory. Not only do you get the full range of inventory management features, but you also have access to advanced 3PL features that allow deep collaboration and coordination with your supply chain partners. You can monitor shipments, track supplier KPIs, and more. These are vital for agile supply chains that are at the core of just-in-time inventory.

Is WareGo the right fit for your business? Find out with a 100% FREE trial.

Start My FREE Trial!2. ABC Classification

Under this method, inventory is classified as either A, B, or C.

Class A goods are the fastest-moving items. These typically generate the most revenue while accounting for a smaller percentage of all goods.

Class C goods, on the other hand, represent the slowest-moving goods. These typically generate a smaller part of the total revenue while comprising the largest portion of all goods, often far more than Class A goods.

Class B goods fall between Class A and Class C inventory.

This inventory system is based on the frequent observation that most sales are produced from the fewest goods. This is somewhat akin to the 80/20 rule, where, more or less, 20 percent of the input produces 80 percent of the results.

This observation can help guide your inventory management strategy.

Class A goods can be placed right next to the main aisles in a warehouse to reduce total travel time for workers who can pick up these highly demanded goods easily in a short time frame.

Class C goods can be placed further away from the main aisles in a warehouse. You can place them deep inside, knowing that the total travel time for your workers will not go up since these goods are required infrequently.

So by placing fast-moving Class A goods close to your workers, and slow-moving Class C goods deep inside your warehouse, you make optimal use of your warehouse space to reduce travel time for your busy warehouse staff.

Hence, ABC classification is an intelligent way of placing goods based on demand to accelerate warehouse operations.

Depending on the type of business, there may be more than just three categories. For example, based on a long-standing demand pattern, a company may divide its products into six categories instead of three and decide their placement accordingly.

An end-to-end WMS can give you access to ABC classification so that categorizing all SKUs is a cinch. You can make your inventory leaner, faster, and smarter with this and other inventory management tools like serialization, slotting, multi-location management, inventory allocation, and more.

3. Materials Requirements Planning (MRP)

Materials requirements planning, or MRP, is all about forecasting the quantity as well as the timing of the goods that will be needed for manufacturing or production without excess inventory.

With this method of planning, managers must walk a fine line to prevent overstocking as well as understocking. Understocking, raw materials will run out and production will come to a halt, leading to financial losses, missed deliveries, and reduced customer satisfaction. Overstocking, high carrying costs will be incurred, and waste can go up, too.

Hence, MRP aims to hit the sweet spot where you have neither too much inventory nor too little. Besides quantity, the timing is also important.

MRP is a key subset of the ERP (Enterprise Resource Planning) system – a massive, highly integrated system that connects all departments and parts of the business into one consolidated platform.

In order to decide what materials are needed, in what quantities, and at what times, planners must analyze production as well as procurement data. They must go through manufacturing schedules, sales, purchase orders, inventory data, and other information for effective MRP management.

As you can see, this is a data-driven strategy that will naturally require the use of analytics and reporting tools to make sense of all this data.

Sales will provide key figures for guiding MRP management. Based on how much customers demand at any given time, planners can arrange for the right amount of material of the right kind to arrive at the right time.

Since this is a strongly data-driven process, you need a good WMS that offers in-depth analytics and instant reports. You can analyze this information from your WMS dashboard to find useful insights that will drive your inventory strategy to new heights. This will also work very well for effective MRP.

Get your free demo to see our cutting-edge platform live in action.

Start My FREE Demo!4. Safety Stock

Safety stock planning is often a key part of inventory management since a certain level of stock must be maintained to prevent stockouts from sudden spikes in demand.

Additionally, safety stock is crucial for maintaining operations in the event of disruptions, delays, or unforeseen circumstances that can disrupt the supply of inventory.

Of course, safety stock should not be excessive; otherwise, it will result in high storage and carrying costs.

The absence of safety stock or even too little safety stock can lead to a high rate of stockouts that disrupt logistics. A few stockouts here and there may not be very significant, but frequent stockouts can greatly reduce supply chain efficiency and thus disrupt operations.

Hence, planning for safety stock is vital to continued and consistently efficient supply chain and operations performance.

Safety stock mitigates the risks arising from uncertainties such as supplier delays, sudden spikes in demand, manufacturing disruptions, restricted cash flow, and inaccurate forecasts.

To calculate optimal safety stock amounts, you need to factor in the various lead times of your suppliers, expected demand, current demand, the inventory turnover rate, and other key considerations.

There are several ways of calculating safety using different formulas, with each formula having its own merits and limitations.

These include Greasley’s Method, Heizer and Render’s Formula, and lead point demand, to name a few.

A futuristic WMS solution will rely on AI tools to analyze your customer demand patterns. These tools will provide you with accurate demand forecasts with which you can easily calculate economically feasible safety stock levels.

5. Economic Order Quantity

Economic order quantity or EOQ refers to the optimal inventory level that a business should keep at hand to maximize profit margins and mitigate stockout risks.

While the basic formula uses constant demand, there are adjustments for seasonal fluctuations in demand as well as for other key factors such as storage constraints and volume discounts.

EOQ works by allowing businesses to spend just enough on inventory so that it fulfills demand adequately without wasting money on excess stock.

AI-powered demand forecasts, analytics, and reports from a comprehensive WMS can help you determine optimal inventory levels that mitigate both stockouts and excess stock.

6. FIFO (First In, First Out)

Determining the amount of inventory at any given time can be an arduous task. Not only is it effort-intensive and time-consuming, but it can also lead to disruptions in production or warehouse operations since accurate stock counts are only possible if inventory is not changed during the counting process.

Hence, a way is needed to determine the value of inventory within reasonable limits. Inventory valuation is extremely important for accounting and tax purposes.

One of the most straightforward methods for evaluating inventory is the FIFO, or first-in, first-out method. Under this method, it is assumed that the business uses or sells its oldest inventory first.

Although it is a fairly simple method, it does have certain drawbacks. For example, during periods of high inflation, this method can yield excessively high gross income levels, which can be misleading to investors and result in larger tax liabilities.

Do you want greater accuracy than the approximate FIFO method? If yes, you can count on a battle-tested WMS to track inventory in real-time. This will give you the full set of data you need to find out which inventory was shipped out of your warehouse. Take out the guesswork with accurate inventory figures and understand your true operational and financial performance.

Our friendly experts will be delighted to explain how WareGo can streamline your business.

Start My FREE Consultation!7. LIFO (Last In, First Out)

The LIFO method, or last-in, first-out method, is the opposite of the FIFO method described above. Here, the assumption is that the newest inventory is sold first or used for production.

As you would expect, it inverts the effects of FIFO. So while FIFO results in unrealistically high profits and lower cost of goods sold during inflationary periods, LIFO results in the opposite during high inflation – lower calculated profits and higher calculated cost for sold goods.

Hence, LIFO has tax benefits since it reduces the taxable income.

While LIFO may have tax benefits, it is not entirely accurate, as you can clearly see. You deserve better – something like a robust WMS that gives you holistic visibility across all locations for real-time inventory information. With this information, you will know exactly which goods you sold without playing the guessing game. Gain accurate information to assess your true performance and make the right decisions with confidence.

8. Reorder Point (ROP)

Reorder point refers to the critically low stock level at which inventory should be purchased.

This sounds quite simple in theory, but certain issues can create complexities. For example, the ROP can fluctuate due to various reasons such as evolving sales figures, changes to supply time frames, seasonal patterns, and more. Hence, it is important to calculate revised ROPs based on these factors as they become significant.

Enterprise-grade WMS solutions help you set the right reorder points that will help you prevent stockouts without facing excess stock. Not just that, these systems automatically reorder stock when its level falls critically low. You are also issued alerts and notifications so that you can take immediate action if the need arises. Besides, these well-designed systems automatically update stock levels after executing each reorder point, so you have access to fully updated and accurate inventory information.

9. Lean Manufacturing

Lean manufacturing entails the use of a continuous improvement approach for trimming any cost that does not help improve product quality or operational efficiency.

Hence, under the lean manufacturing strategy, a close watch must be kept on stock for any signs of excess inventory that can tie up working capital, incur high costs, waste space, and increase workload for warehouse staff.

Lean manufacturing has close ties to just-in-time inventory management – both work in unison to trim costs that don’t add value. This way, you can boost product quality and sell goods at lower prices to make your business more competitive.

Strong WMS solutions can help you track inventory in real-time across multiple locations so you don’t run into excess inventory. These proven solutions are extremely helpful, in fact, indispensable for maintaining lean inventory.

10. Dropshipping

Dropshipping has seen a steady increase in popularity since sellers don’t have to store any inventory in warehouses. Instead, sellers can take orders directly from customers and pass on these order details to their suppliers for order fulfillment and product shipment.

Dropshippers often run websites where they market products made by their suppliers. Hence, they attract website visitors to their online platforms through digital marketing and convert them into paying customers.

The most obvious advantage of dropshipping is that no investment is necessary for warehouses and inventory.

High scalability is also another key benefit. Dropshippers can easily scale their business by reaching out to multiple suppliers.

Here again, a powerful WMS can offer superlative value, such as omnichannel sales support that syncs inventory across all your websites, e-commerce platforms, and online marketplaces. Thanks to this synchronization, you will have accurate stock levels and won’t run the risk of overselling. You can also collaborate and coordinate more closely with your suppliers to boost order fulfillment rates.

Check out our price plans for the most competitive rates

Check price plans!Types of Effective Inventory Management Techniques

Businesses can use different types of inventory management techniques based on their activities and requirements. Perpetual inventory, periodic inventory, and manual inventory are the three main methods for managing inventory.

The manual method of inventory management is the least sophisticated type and therefore, it has the least accuracy. On the other hand, perpetual systems have the highest level of sophistication since they use cutting-edge technology and therefore provide the most accurate and fully updated inventory data.

Manual Inventory System: Physical counts are necessary to keep track of stock levels under this method. The figures are noted down on paper or kept in a spreadsheet. This method can work just for very small businesses. Any other business definitely needs more sophisticated methods than manual counting and manual recording to track inventory. While spreadsheets might work in the short term, they soon become chaotic as time passes, transactions rise, and inventory expands.

Periodic Inventory System: These are concerned with both periodic and manual counts. As inventory is stored and sold, it is recorded by means of periodic counts. Barcode scanning can help accelerate the process and maintain high precision for inventory data. The locations as well as stock levels are maintained in a database.

Perpetual Inventory System: These are the most sophisticated systems that keep you up to date with the latest and most accurate inventory data. They use barcode and RFID scanning to record inventory purchases. POS terminal support helps record sales automatically. These modern systems can accurately update inventory information with each sale or purchase. They can send automatic alerts and notifications if stocks fall too low. You can even program them to order automatically when stocks fall below specified critical levels.

Advantages of Inventory Management

Maximizing profit margins and achieving other business objectives largely depend on inventory management done right. While inventory management is no doubt a complex endeavor, it does yield many lucrative benefits. Here are some.

No Overselling: Finalizing sales with customers only to realize that you don’t have stock at hand is a major problem. Besides the financial cost of lost sales, overselling causes customer dissatisfaction.

Overselling is largely the result of inaccurate stock figures. Good inventory management can prevent this by smart cycle counts, barcode/RFID scanning, POS terminal support, and automatic stock updates for each transaction.

No Overstocking: Excess stock increases inventory carrying costs, consumes limited warehouse space, and incurs financial losses due to unsold goods. A state-of-the-art WMS like WareGo can prevent this via accurate demand forecasts and inventory planning. The system can suggest optimal inventory levels based on historic demand patterns. This way, you have neither too much stock nor too little.

Accelerated Order Fulfillment: Inventory management techniques like smart serialization, slotting, ABC classification, and multi-location management can help your team process inventory faster for quick and accurate order fulfillment. Fast-moving inventory is kept within easy reach to reduce travel time for your workers. Since inventory is serialized and documented correctly, workers won’t have to struggle with finding misplaced inventory. Order fulfillment speed and accuracy go up as a result.

Precise Order Fulfillment: RFID/barcode scanning, POS terminal support, omnichannel sales support, and automated stock updates for each transaction mean that costly errors in order fulfillment are greatly minimized. These functions, along with inventory synchronization through integrations, reduce human intervention and subsequent errors.

Powerful Insights: Inventory management software has deep analytics and instant reports that provide strong insights for cost-saving and profit-boosting opportunities.

Better Supply Chain: Warehouse management software like WareGo has built-in 3PL support with which you can coordinate better with your suppliers, monitor their performance, and save costs. You can find the best shipping rates and the fastest delivery dates to improve supply chain performance.

Great Customer Experience: With fast and accurate order fulfillment, you can greatly enhance customer satisfaction. When customers receive their goods on time, they will rely on you to fulfill demand and thus keep coming back for more.

Easier Warehouse Management: Multi-location monitoring and complete visibility across the supply network allow for better supply chain management. A good WMS provides a simple dashboard that gives you access to all necessary information about your supply chain. Spreadsheets can’t do this for you.

Automation: Inventory management via inventory software helps you automate many recurring tasks like inventory purchases and sales returns. The software tracks inventory levels in real-time and can automatically reorder inventory when stocks fall to critical levels. It can also automate supplier payments, customer invoicing, stock counts, and several other time-consuming processes. You save time, money, and effort this way.

Lean Manufacturing: Under this business philosophy, you order the right amount of inventory of the right kind at the right time to support your manufacturing and warehouse operations. The goal here is to avoid overstocking, which increases costs, consumes storage space, and complicates management. Hence, lean manufacturing saves costs and is not possible without robust inventory management.

Scalability: As your business grows and your SKU list expands, you will need a dependable management system to facilitate this expansion. Modern inventory software helps you implement efficient inventory management through which you can scale your products and business seamlessly.

Compliance: Certain strongly regulated industries like pharmaceuticals and automakers need to track all inventory accurately to execute product recalls successfully. The food and beverage industry also needs inventory tracking to prevent the sale of expired goods and stock wastage. Accurate stock levels are necessary for accounting and tax compliance. Hence, inventory software is instrumental in robust inventory management, which is necessary for compliance.

Integrated Business Systems: Your business may have multiple systems like an ERP, CRM, accounts software, ecommerce platforms, online marketplaces, and more. You must sync your inventory with these tools so that all transactions and goods movement can be recorded automatically. This reduces manual data entry and subsequent human errors and delays. WareGo provides over 200 integrations to consolidate your business tools into a unified platform that serves as a single source of truth.

Bottom Line

While understanding the basics does matter, you don’t need a professional degree in inventory management to maintain lean, smart, and agile inventory. All you need is an end-to-end WMS solution like WareGo, that provides the full suite of enterprise-grade features at knockdown rates, highly intuitive self-explanatory layouts that non-experts can start using right away, and a flexible and secure cloud architecture that scales seamlessly with your growing business.

The software helps you take your inventory management strategy to the next level. Your business gains cost savings, higher profit margins, and faster operations.

Our friendly experts can outline in simple words how WareGo helps.

Chat With Us!FAQs

What are the four types of inventory management?

The four types of inventory management include the just-in-time, ABC classification, FIFO, and LIFO, as well as Economic Order Quantity systems. These are some of the most popular methods for inventory management, although there are some more.

What are the five stages of the inventory management process?

The five stages of the inventory management process entail planning, procurement, storage, control, and distribution.

(1) Planning covers demand forecasts made via seasonal changes, market movement, and historical data. This step decides how much and what type of products to stock.

(2) Procurement entails sourcing inventory from suppliers. After negotiating terms, shipment dates, and prices, businesses place orders and track shipments.

(3) Storage involves receiving shipped goods and placing them intelligently in the right locations using serialization, slotting, ABC classification, and other methods for easy retrieval that will accelerate operations.

(4) Control deals with tracking stock levels via WMS solutions, carrying out cycle counts, maintaining safety stock, calculating reorder points, and so on.

(5) Distribution is about shipping finished goods to customers with precision and updating stock levels when goods exit.

What is the most common method of inventory management?

ABC analysis is one of the most widespread methods of inventory management. It follows the 80/20 rule, meaning that around 20% of the input drives 80% of the results. Class A goods generate the most sales but make up only a small percentage of total goods. Workers keep these fast-moving items within easy reach to cut travel time. Class C goods generate the least sales but make up a large share of total goods, so businesses place them deeper inside the warehouse. Class B goods fall between these two categories. Under ABC analysis, businesses place goods strategically based on demand to speed up warehouse operations. Instead of sticking to just three categories, some businesses create more categories based on their observations.

What is inventory management?

Inventory management is at the core of business operations since it is concerned with the streamlining, optimization, tracking, and forecasting of inventory. By ordering the right amount of stock at the right time at the right place, a business can reduce inventory holding costs, accelerate operations, and improve order fulfillment accuracy to enhance customer satisfaction.

What is the 80/20 rule for inventory?

The 80/20 rule for inventory assumes that 80% of sales come from 20% of your inventory. This observation appears not only in inventory but also across many other fields. Businesses often call it the 80/20 rule. You need to factor in this recurring phenomenon when managing inventory. ABC classification helps you do this. Class A goods (usually about 20% of stock) move quickly and generate around 80% of sales. Identifying these items lets you place them within easy reach of warehouse staff, cut travel time, speed up inventory processing, and streamline warehouse operations. WareGo offers ABC classification support out of the box.

What is the golden rule for inventory?

The golden rule for inventory is that you should have enough stock to fulfill demand without excess inventory levels. You can thus serve customers without facing common problems like overstocking and stockouts. Accurate demand forecasting and inventory planning are necessary for this. WareGo can help you in this regard with its AI-powered tools.