Inventory plays a crucial role in the success of any business that supplies physical products. It encompasses everything from ordering stock and managing inventory to fulfilling orders. Due to the unpredictable nature of product demand and changing trends, managing inventory can be challenging, and mistakes can prove to be costly.

Inventory cost reduction isn’t about money; it’s about being efficient and optimized to ensure long-term scalability and success. Over several years of experimentation and real-world implementation, various inventory control methods, including the use of advanced inventory management system software and Just-in-Time Inventory (JIT) management, have proven effective in reducing inventory costs and increasing productivity.

In this blog, we will break down what inventory costs are. And how they can be optimized by providing 11 innovative inventory cost reduction methods, helping you cut unnecessary costs and focus more on growth and success.

WareGo is an advanced inventory management software that has proven to reduce inventory costs and increase productivity.

Try NowTable of Contents

What Are Inventory Costs

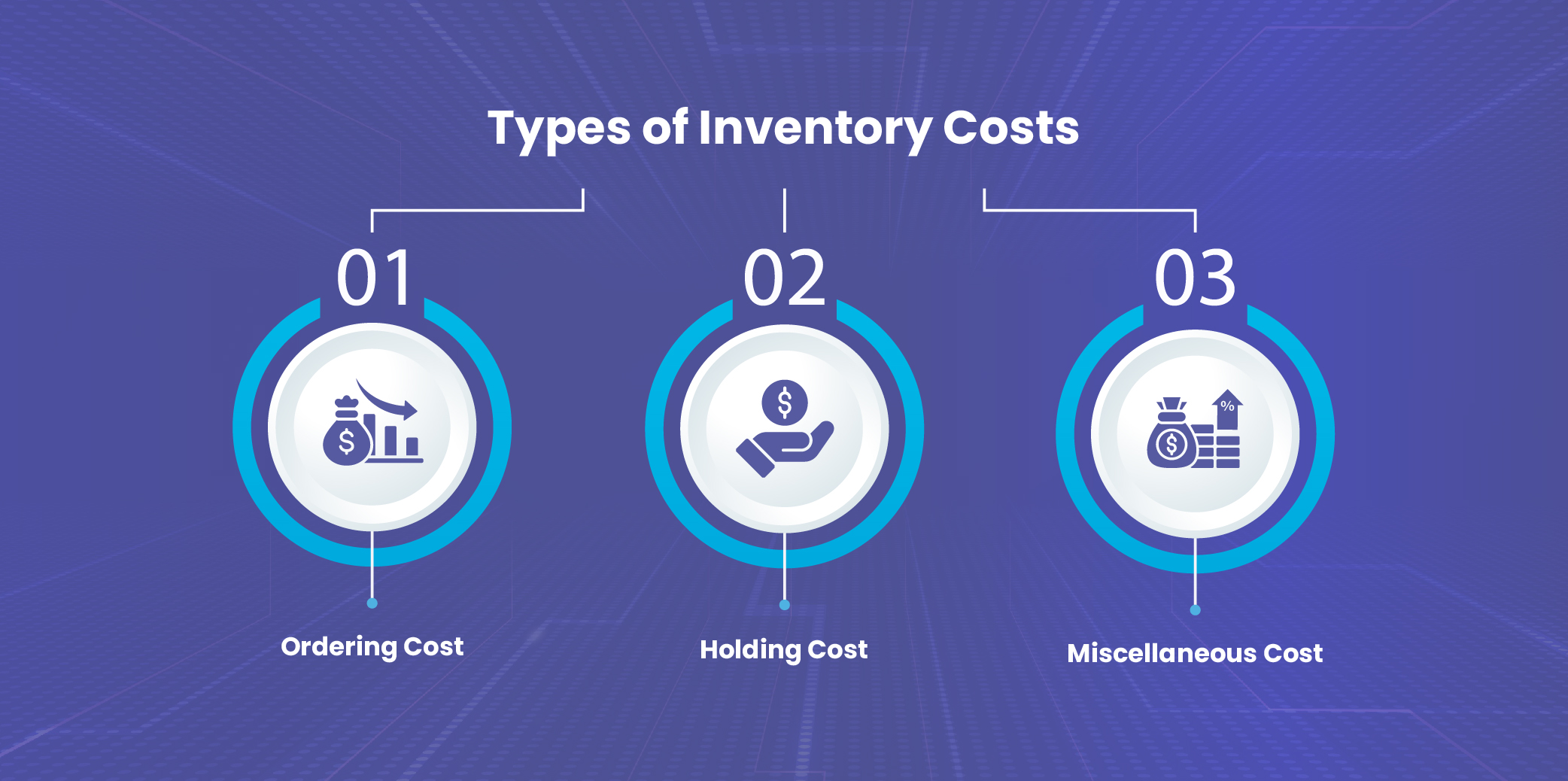

Inventory cost doesn’t mean a fixed singular price tag on “inventory”; instead, inventory costs include the total expenses a business faces in purchasing, storing, managing, and shipping its product. If left unchecked, these costs can gradually accumulate to substantial amounts, negatively impacting profits and sometimes even resulting in a net loss. The first step to reducing these expenses effectively is to understand the different types of inventory costs.

Ordering Costs

Ordering costs include more than just the price tag of the product you are buying. These are the expenses a business incurs each time it restocks its inventory, including administrative work, communication, invoice processing, shipping, and handling. Even small mistakes in amount or timeline can result in significant overhead.

Optimizing ordering costs doesn’t necessarily mean reducing the number of orders; it also involves minimizing the total cost of each order. You can utilize automated reorder systems that replenish stock after a predetermined time, consider ordering in bulk, or enter into long-term supplier contracts.

Moreover, you can learn patterns in demand. For example, as a clothing store, during winter, you can increase orders of Halloween-themed clothes and costumes, while in summer, you can stop taking orders altogether. With the right strategy, you can effectively mitigate the risks of shortages and overstocking.

Holding Costs

Holding costs, also known as carrying costs, refer to the money required to store inventory that hasn’t been sold yet. Holding cost is not limited to warehouse rent; it also includes utility bills, insurance costs, security, and employee salaries. If your stock sells slowly, it will continue to incur storage costs.

Moreover, some stock can be damaged, outdated, or even stolen, adding to the damages that you have to swallow, wasting money that could have been spent elsewhere. This is why a balance is required to be efficient, neither too little stock that it fails to meet demand, nor too much that it becomes a financial burden.

To minimize holding costs, you must improve forecasting, utilize lean inventory methods, and optimize warehouse management. Using an advanced warehouse management system may initially incur expenses, but it is one of the most effective ways to reduce holding costs in the long run.

Miscellaneous Costs

Apart from ordering and holding costs, there are numerous other minor or conditional expenses. These extra expenses, labeled as “miscellaneous costs,” include shortages that can occur when demand is high but the stock runs out, resulting in lost sales and dissatisfied customers.

If you have taken out a loan for your business, the longer you take to repay it, the more interest you will incur. Providing customer service will cost money, as it resolves user errors, offers refunds, and cancels orders. Reducing these costs requires more thoughtful planning, effective inventory management, and improved quality control.

| Ordering Costs | Holding Costs | Miscellaneous (other costs) |

| Purchasing costs | Warehouse rent | Customer support |

| Trandporting csots | Spolied / Damaged Goods | Shortages |

| Receiving cost | Stolen products and equipment | Lost sales |

| Reordering csot | Utility bills | Interest rates |

| Insurance Cost | ||

| Security/ Employee Salary | ||

| Obsolete Stock (Stock that will not sell) | ||

| Overstocking / Understocking |

We help businesses automate stock movement, cycle counts, and order processing.

Get Started11 Inventory Control Methods For Cost Reduction

There is nothing wrong with reducing inventory costs and being cost-efficient; actually, it’s how most businesses succeed by being as efficient and productive as possible. Inventory costs can easily rise due to poor planning, excess orders, and stockouts, resulting in substantial damage to your business. By making the following inventory reduction strategies, you can significantly reduce inventory costs.

1. Optimize Reorder Points

Reorder points are the stock level at which you place another order to prevent running out of inventory. For example, if you sell 10 bottles a day and order a stock of 100 bottles that takes 2 days to arrive, you should reorder the stock when you have 20 bottles left. By the time you run out of inventory, the new order will have arrived.

Calculate the Economic Order Quantity (EOQ) and reorder points to identify the exact amount to order at the ideal time. EOQ is the optimal number of units to restock each time. Calculating economic order quantity and reorder points will reduce the chances of overstocking, shortages, and holding costs.

2. Improve Supplier Terms

Demand a better agreement with your supplier or consider switching to a distributor that offers more favorable terms. Negotiate prices, reduce minimum order quantities (MOQs), and aim for faster lead times.

With better supplier terms, you can order smaller but more frequent stocks, cutting storage costs, mitigating the need for excessive buffer stock, and reducing the risk of obsolete stock. Having a strategic supplier relationship allows your shelves to be stocked while also being cost-effective.

3. Use a Lean Warehouse Design

Lean warehouse design involves focusing on reducing unnecessary steps and optimizing necessary ones in the processes of receiving, shipping, and storing items. For example, storing packages in a way that maximizes space utilization, utilizing SKU velocity zoning, clearly labeling areas, maintaining organization, and effectively utilizing vertical space.

Stock Keeping Unit (SKU) velocity zoning involves organizing a warehouse based on the velocity of each SKU, which refers to the rate at which it is sold. High SKU velocity (quick-selling) items should be placed near the dispatch/shipping area, while low SKU velocity (slow-selling) items should be placed in the back. Using this method significantly improves efficiency and reduces costs.

Using a lean warehouse design contributed to efficient inventory management, improved visibility, and overall reduced inventory costs.

4. Utilize an Inventory Management Software

One of the most critical inventory reduction strategies is using an advanced Inventory Management Software. While many applications claim to streamline workflows and increase efficiency, utilizing software with modern features, such as multi-warehouse support and vehicle management, or using an advanced AI-powered warehouse management system software, will yield a more significant improvement.

These systems help automate stock tracking, update reorder points, and facilitate easy integration of inventory data with other departments. Moreover, a reliable inventory management software will mitigate the risks of overstocking and stockouts, and also provide analytics for data-driven decision-making and forecasting.

This inventory management software isn’t just marketing talk or buzzwords; they have been rigorously tested and implemented in real-world scenarios. This study, published by SciTePress, demonstrates how AI, IoT, and real-time inventory management can be leveraged to enhance business efficiency and accuracy.

Our end-to-end simplifies your supply chain for faster and accurate logistics.

Get a Free Demo5. Better Demand Forecasting

Better demand forecasting is another crucial inventory control method for maintaining adequate inventory levels, thereby minimizing the risks of understocking and overstocking. Using past sales, market trends, seasonal patterns, and detailed analytics, you can predict to a certain degree what items will be in demand at what time of the year.

Having an accurate demand forecast can help avoid over-ordering slow-selling items and prevent waste of storage space. Your inventory management system should track your inventory in real-time and be integrated with a forecasting system to predict product demand accurately. Strong forecasting can reduce waste, stock shortages, and obsolete inventory.

6. Prioritize Quick-Selling Items

Prioritizing products that are in high demand and sell quickly can improve profits and decrease storage costs. Using your forecasting system, prioritize fast-moving items over slow-moving ones, as they can often occupy more space than anticipated.

Low SKU velocity items can be ordered conditionally on demand, while high SKU velocity items should be ordered more frequently. This method, often referred to as ABC analysis (A for fast-selling, B for moderately selling, and C for slow-selling), helps you identify the products that matter most and can generate the most revenue.

7. Audit Regularly

Routinely auditing your inventory helps you catch errors in counting, detect spoiled or damaged goods, identify discrepancies before they become costly, and prevent potential theft. Audits can be conducted in two forms: scheduled complete audits and spot checks.

Auditing ensures that your physical products match the digital records while also building accountability, reducing mismanagement (whether intentional or unintentional), and providing crucial data and reports for forecasting and reorder points.

8. Use a Low-Risk Inventory Model

Some models, such as Just-in-Time (JIT) inventory or dropshipping, significantly reduce the need to have a proper stock available at all times. These models put the storage and holding burden on suppliers, ensuring you only store products that are needed.

A Just-In-Time inventory model involves ordering products only when needed, thereby keeping your stock level as low as possible and reducing holding costs. In dropshipping, you never store the product; whenever someone places an order, you get the product from the supplier and ship it directly to the customer.

Moreover, you can use a consignment model where you store the supplier’s product in your inventory, but only pay them once the product is sold. Remaining or obsolete stock is often returned to the supplier for credit. This flexibility reduces significant inventory risks such as overstocking or outdated stock.

9. Improve Supply Lead Time

Supply lead time refers to the time duration between placing an order and receiving it. Having a short lead time means you can operate your business with less inventory without worrying about running out of stock.

You can improve lead time by partnering with local and regional suppliers, optimizing order processing stages, and securing a priority slot from the supplier. Having a faster lead time means you can work safely with smaller stock levels, utilize free warehouse space, and easily match fluctuating demand.

10. Track Key Performance Indicators

Tracking Key Performance Indicators (KPIs) is crucial for gaining insight into your inventory system. KPIs such as Days Inventory Outstanding (DIO) indicate how long your products remain in your warehouse before being sold. At the same time, the Inventory Turnover Ratio reveals how frequently you replenish your stock.

A low turnover ratio can mean you overstock your inventory, or the demand is not as high as you expected. These KPIs indicate how well your business and inventory control are going. By tracking these, you can accurately pinpoint errors, mistakes, and inefficiencies, reducing inventory costs and making data-driven decisions.

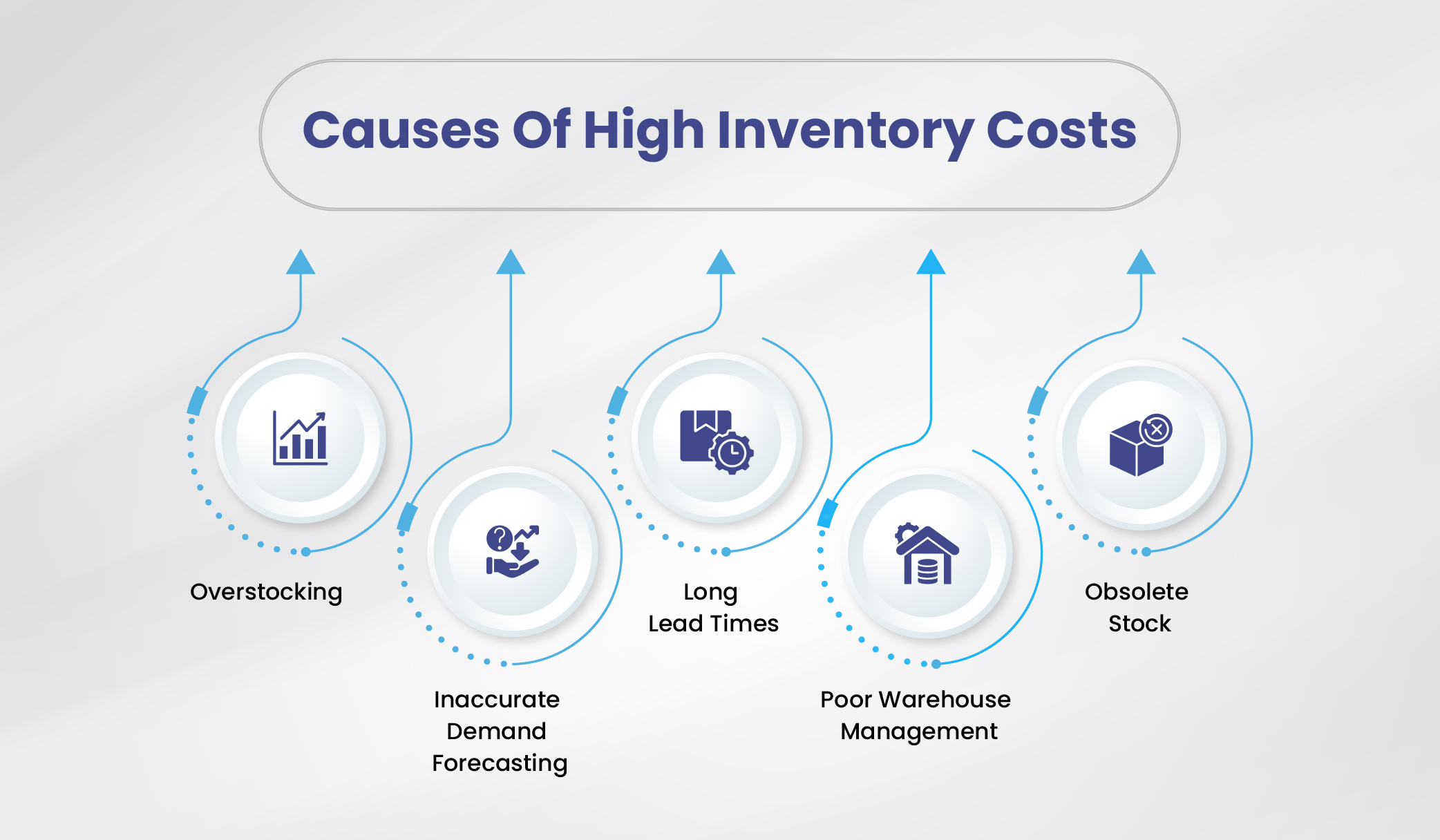

Common Causes of High Inventory Costs

Inventory control is a delicate process that can be easily messed up without realizing it. It’s all about getting the right balance between stock and demand. If you don’t practice proven inventory reduction strategies, the cost of maintaining that stock can slowly increase over time. Here are some of the factors that significantly contribute to inventory costs.

Overstocking

Overstocking is one of the primary reasons businesses end up with an excessive amount of products that sit in the warehouse, waiting to be sold. Not only do they occupy space that could have housed a more profitable product, but they also require money to maintain and manage.

Whether it’s due to attractive bulk discounts or inaccurate forecasting, overstocking can prove detrimental to your business and lead to significant losses.

Inaccurate Demand Forecasting

Inaccurately predicting consumer demand is what primarily drives overstocking or understocking. Poor forecasting, often due to a lack of expertise and limited data, can lead to increased holding costs for storing products or result in lost customers to competitors due to stockouts.

Long Lead Times

If your supplier has a slow lead time, it can force you to operate on higher inventory levels to avoid the risks of stockouts and shortages. For example, if you sell 10 bottles a day and your supplier delivers stock in 4 days, you would need to have at least 40 bottles on hand before ordering a restock. However, if your supplier delivers within a day, you can operate with as few as 10 bottles remaining.

This buffer stock provides safety against shortages, but it can significantly increase your holding costs.

Poor Warehouse Management

Poor warehouse management includes disorganized storage, manual inventory tracking, unclear labeling, and inadequate space utilization. Having a poorly managed warehouse, often due to a lack of a proper warehouse management system, will increase handling costs, processing time, and the likelihood of misplacement and errors.

Using poor warehouse management software or relying on manual processes can significantly increase the costs of handling and managing your stock.

Obsolete Stock

Products that fall out of trend, expire, or simply don’t sell due to minimal demand can become a burden to maintain. They occupy valuable storage space and utilize unnecessary capital to store. Having a proper system that finds and removes these items can significantly increase storage efficiency and decrease inventory costs.

WareGo is a cloud-based automated solution for your business problems

Start Now!Conclusion

Reducing inventory costs is a crucial step to ensure your business stays efficient and competitive, but it doesn’t mean cutting corners or lowering orders outright. Several inventory control methods have been established over the years that have proven effective in reducing inventory costs without compromising growth.

By implementing inventory reduction strategies, such as utilizing advanced warehouse management software, improving demand forecasting, and optimizing order points, you can minimize waste, increase efficiency, and reduce losses. Whether you are a small business or a well-established firm, inventory control isn’t something you can slack off on.

Frequently Asked Questions

How to reduce inventory carrying cost?

You can reduce inventory carrying costs by optimizing reorder points, negotiating more favorable supplier terms, improving lead times, utilizing an inventory management system, adopting a lean warehousing model, and strategically employing lower-risk business models. Moreover, you can track KPIs to improve demand forecasting and identify inefficiencies and mistakes.

How do you decrease inventory?

To decrease inventory without slowing down growth or increasing the risk of shortages, start by identifying slow-moving or obsolete stock and selling it through sales and discounts. For the future, utilize demand forecasting accurately to minimize the risk of overordering and adjust reorder points for more effective stocking. You can switch to lower-risk models, such as JIT, Dropshipping, and Consignment, to reduce or eliminate the need to maintain an inventory.

How to manage inventory costs?

Managing inventory costs begins with optimizing your order process by adjusting reorder points and securing more favorable supplier terms. You can utilize an advanced inventory management system to enhance automation, track inventory levels, and minimize the risk of overstocking. You can switch to a low-risk business model, such as JIT, to reduce the need for a stocked inventory 24/7.

What is the 80/20 rule, and how does it relate to inventory?

The 80/20 rule, also known as the “Pareto Principle,” suggests that 80% of outcomes stem from 20% of causes. In inventory management, it means that when 20% of your products generate 80% of your revenue, then they should not be treated equally to the other 80% of your products. These 20% are considered the A group, which means they must be focused on; the other is classified as the B group, which includes moderate-selling goods. The B group must be managed carefully, while the rest are referred to as the C group, which is not worth significant investment.