Every growing company eventually realizes that spreadsheets, emails, and manual tracking no longer work for managing inventory and orders. The bigger the operation, the harder it gets to stay efficient. That’s when the discussion about ERP vs WMS begins.

The choice is not as simple as “pick one.” Both Enterprise Resource Planning (ERP) systems and Warehouse Management Systems (WMS) bring value, but in very different ways. ERP covers the entire business ecosystem—finance, HR, procurement, supply chain, and more. WMS focuses only on warehouse operations efficiency—tracking bins, optimizing picking routes, and managing outbound logistics.

The confusion happens because both overlap in inventory management. But they solve different problems. ERP tells you what you own; WMS tells you where it is, how to move it, and how to fulfill orders faster.

In this blog, we’ll break down:

- What is ERP vs WMS and their core differences

- A clear side-by-side WMS vs ERP comparison table

- ERP vs WMS across industries

- ERP vs WMS by business size: startups, mid-level, scaleups, and enterprises

- Top ERP and WMS software providers in 2025, with pricing and warehouse-specific notes

- Which system is better for cost, scalability, and long-term ROI

If you’re searching for warehouse management software, or trying to decide if your business needs ERP first, this article will give you the clarity you need.

Table of Contents

Difference Between ERP & WMS

ERP came first for many companies, solving finance, procurement, HR, and production planning problems in a single package. As warehousing became more complex, ERP vendors added inventory modules. These modules handle counts and basic stock visibility but rarely address bin-level operations, wave sequencing, or labor optimization.

WMS, on the other hand, is designed specifically for precision warehouse execution. It tracks items at bin, serial, lot, and expiry levels. It optimizes picking paths, assigns work to scanners or robots, and controls conveyors and pack lines. For businesses where fulfillment accuracy, speed, and labor efficiency matter, WMS delivers immediate operational returns. ERP delivers strategic control for organizations needing integrated forecasts, accounting, and enterprise reporting.

What is ERP?

ERP (Enterprise Resource Planning) is a comprehensive system that integrates core business functions such as finance, procurement, HR, and production planning. ERP’s inventory modules allow location-level counts, general order processing, and basic reporting. Its strength lies in enterprise-wide planning, consolidated reporting, and cross-department visibility, making it ideal for strategic control and large-scale operations.

What is WMS?

WMS (Warehouse Management System) is a specialized tool focused on optimizing warehouse execution and fulfillment. It offers deep inventory visibility down to bin/slot, lot, serial, and expiry levels. WMS supports wave and batch picking, cartonization, labor management, task interleaving, and automation integration. This precision helps improve order accuracy, throughput, and labor productivity.

Connect WMS workflows that cut touches and errors in week one.

Talk to a WMS ExpertERP vs WMS Comparison

| Capability | ERP | WMS |

| Primary focus | Enterprise-wide planning & finance | Warehouse execution & fulfillment |

| Inventory depth | Location-level counts | Bin/slot, lot, serial, expiry levels |

| Order handling | General order processing | Wave, batch, pick/pack, cartonization |

| Labor management | Basic reporting | Task interleaving, real-time scorecards |

| Automation support | Limited | Robotics, conveyors, devices |

| Best ROI | Finance, procurement, MRP | Order accuracy, throughput, labor cost |

Choosing Between ERP & WMS

A clear choice comes from your pain points. If order errors, late shipments, and long cycle counts drive costs, WMS delivers measurable operational improvements quickly. Implementation can be targeted warehouse-by-warehouse, improving picking accuracy, cycle times, and throughput.

If cross-department visibility, consolidated financial reporting, and unified supplier/customer records matter more, ERP becomes the strategic hub. Large organizations rarely choose only one path indefinitely. A common evolution is to adopt WMS first to resolve warehouse pain points and later integrate ERP for enterprise-wide control.

ERP vs WMS: Pros & Cons

The ERP vs WMS debate often comes down to business priorities. ERP is powerful for enterprises that need finance, HR, and compliance under one umbrella. But for businesses where warehouse operations drive customer experience and margins, a standalone WMS usually delivers faster results and better ROI. Let’s look at the pros and cons of each side.

Pros of ERP Systems

- Unified platform: ERP brings finance, HR, procurement, and supply chain into a single system, streamlining back-office work.

- Global compliance: Systems like SAP and Oracle NetSuite come preloaded with international tax, audit, and regulatory compliance tools.

- Scalability for enterprises: Large corporations benefit from ERP’s ability to handle multiple entities, currencies, and cross-border operations.

- High-level insights: Dashboards and reports give executives a big-picture view across all business functions.

Cons of ERP Systems

- High investment: Licensing and rollout costs can be substantial, making ERP less ideal for smaller or warehouse-first businesses.

- Slow deployment: Implementations may take months or years before delivering value.

- Warehouse depth is limited: Most ERP systems offer basic warehouse modules but often lack advanced execution features like wave picking, dock scheduling, or robotics integration.

- Customization challenges: Tailoring ERP for complex floor-level workflows is possible but usually requires expensive add-ons or consultants.

Pros of Standalone WMS

- Purpose-built for warehouses: WMS platforms are designed to optimize inventory, labor, and automation from the ground up.

- Quick time-to-value: Cloud WMS solutions can go live in weeks, providing immediate operational improvements.

- Easy for staff: Intuitive, mobile-friendly workflows make adoption smoother for warehouse teams.

- Constant innovation: WMS vendors continuously release updates around automation, AI, and predictive picking to stay ahead of warehouse challenges.

- Better ROI for warehouse-first firms: For companies where fulfillment speed and accuracy directly impact revenue, WMS delivers measurable results faster than ERP.

Trade-Offs of Standalone WMS

- Integration needed: WMS thrives when connected to ERP or accounting software, but modern cloud APIs make integration easier than ever.

- Enterprise-wide coverage: WMS focuses on warehouse execution, so businesses needing HR, finance, and procurement tools will still need a lightweight ERP — but this modular approach often reduces overall risk.

- Global scale requires planning: Multi-region rollouts are possible but may require phased integration with ERP for reporting. For most growing businesses, this hybrid path works better than going all-in on ERP too early.

ERP vs WMS — At a Glance

| Aspect | ERP | Standalone WMS |

| Scope | Enterprise-wide coverage | Warehouse-first execution focus |

| Cost | High upfront, scales over time | Lower upfront, predictable ROI |

| Deployment | Long, resource-intensive | Fast, cloud-driven, minimal IT overhead |

| Features | Broad but shallow in warehousing | Deep, warehouse-specialized |

| Scalability | Global, multi-entity | Scales warehouse ops, integrates with ERP |

If your warehouse is the heartbeat of your business — whether that’s eCommerce, distribution, or 3PL — a standalone WMS is usually the smarter first move. It solves operational pain faster, drives immediate cost savings, and prepares your company for scalable fulfillment. ERP still has a role in financial governance and compliance, but most warehouse-driven businesses see the biggest impact by starting with WMS and integrating ERP when the time is right.

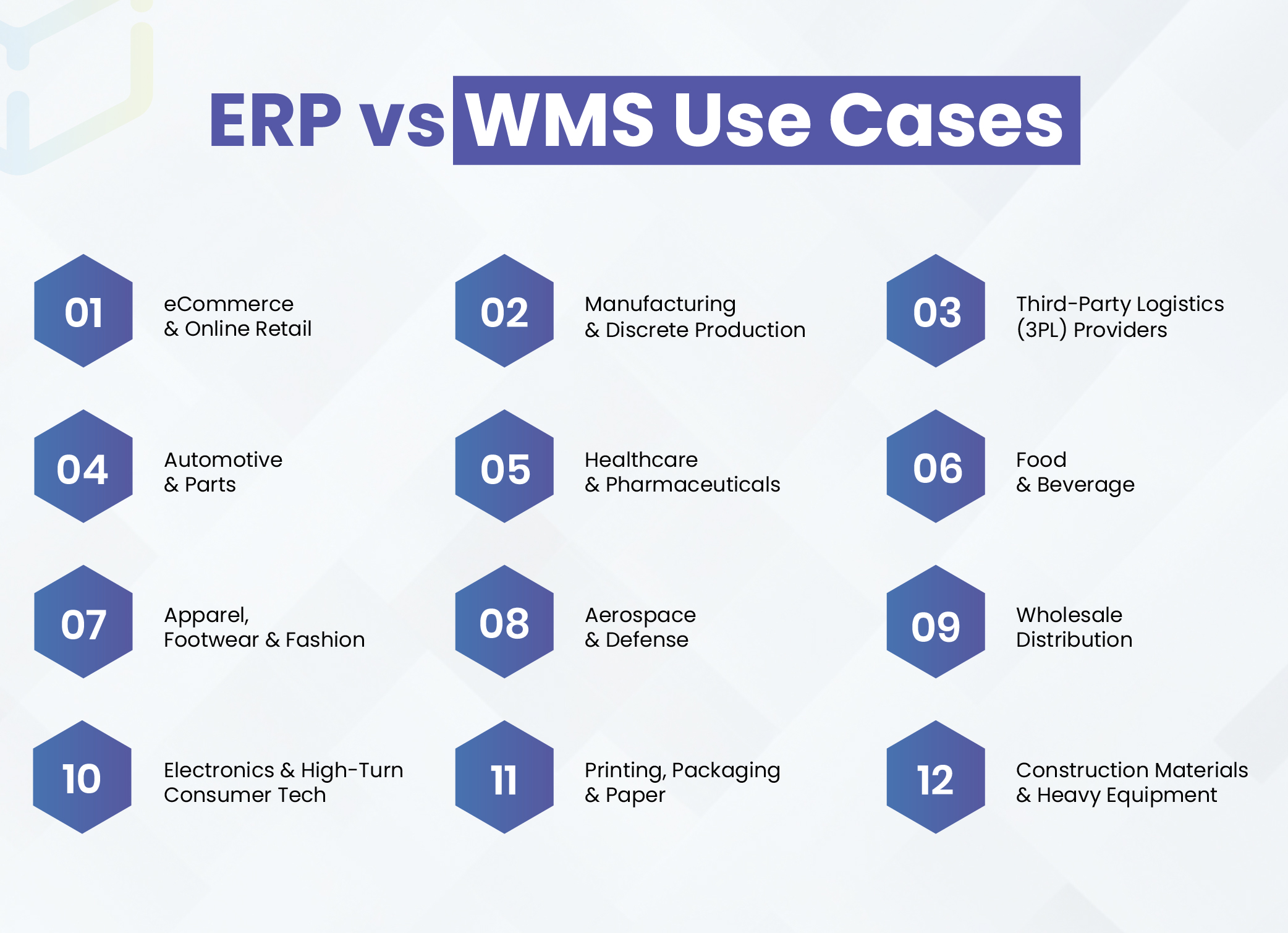

ERP vs WMS Across Industries

The impact of ERP vs WMS varies widely across industries. From eCommerce and retail to manufacturing, 3PL, and healthcare, each sector faces unique warehouse challenges — and the right system choice can define efficiency, cost savings, and scalability

eCommerce & Online Retail

Online retail demands speed and accuracy. Customers expect same-day or next-day delivery. Returns are frequent. A WMS directly improves picking accuracy, pack optimization, and outbound velocity. It handles promotions, bundles, and high SKU counts. A pure ERP will track sales, revenue, and reorder points, but it will not optimize the picker’s path or manage parcel carrier integrations at the required depth.

Verdict: WMS-first; integrate ERP for finance and reporting as sales scale.

Scenario: A mid-size apparel brand launches marketplaces across three countries. They implement WMS to handle high SKU churn and fast returns. As revenue stabilizes, they add NetSuite to unify accounting and reconcile marketplace payouts automatically.

Manufacturing & Discrete Production

Manufacturing needs material planning, scheduling, and shop-floor control. ERP systems drive bill of materials, MRP runs, and supplier purchasing. But warehouses for manufacturing require accurate inbound handling and kitting software for production. A WMS ensures raw materials arrive, sit in proper zones, and get pulled in the right lot and sequence. This reduces line stoppages and material waste.

Verdict: ERP backbone + WMS for material flow.

Scenario: A plastics manufacturer uses SAP ERP for MRP and integrates Warego to ensure raw resin lots feed production lines in sequence, preventing contamination and production delays.

Third-Party Logistics (3PL) Providers

3PLs operate warehouses for multiple clients. Their success rests on per-client inventory segregation, billing accuracy, and SLA compliance. WMS supports multi-client tenancy, serial tracking, and SLA alerts. ERP helps 3PLs handle contracts, invoicing, and finance. However, the day-to-day value to clients comes from a WMS that can offer client-specific routing, pack lists, and reporting.

Verdict: WMS is core; ERP supports financial consolidation.

Scenario: A regional 3PL implements Warego to manage client-specific SKUs, then plugs NetSuite for consolidated invoicing and margin reporting.

Automotive & Parts

Automotive supply chains demand JIT deliveries, traceability, and lot control. An ERP governs supplier contracts, demand planning, and long-term forecasting. A WMS guarantees that the right part, right serial or lot, reaches the assembly line exactly when needed. Traceability is crucial for recalls. WMS supports serialized parts and exact location tracking within complicated yard and warehouse networks.

Verdict: ERP + WMS hybrid.

Scenario: A tier-1 supplier runs SAP ERP for planning and SAP EWM at the warehouse to deliver parts to assembly lines on a just-in-time schedule.

Healthcare & Pharmaceuticals

Healthcare warehouses must meet compliance, control batch numbers, and manage expiries. Pharmacy chains and drug distributors need strict recall capability and traceability to the batch and lot. WMS handles temperature control zones, quarantine holds, and rapid recall workflows. ERP supports purchasing, procurement, and finance, but cannot manage the warehouse-level compliance that regulators require.

Verdict: WMS primary for compliance; ERP for enterprise control.

Scenario: A pharma distributor implements Infor WMS to ensure cold chain control and integrates with Dynamics 365 for procurement and finance.

Food & Beverage

Perishability changes everything. Fresh produce requires a lot and expiry awareness. Frozen goods need temperature and thaw tracking. WMS handles FIFO/LIFO rules, pallet tracking, and hold/release workflows. ERP supports demand forecasting and supplier management but won’t enforce per-pallet temperature flags or rapid rotational picking on the floor.

Verdict: WMS-driven.

Scenario: A beverage co-packer deploys Warego to manage FIFO on the floor and uses NetSuite for supplier settlements and costing.

Apparel, Footwear & Fashion

Apparel faces seasonal peaks and high SKU proliferation. Fast fashion needs quick replenishment. WMS helps with split-case picking, pack optimization for size and color, and returns processing. ERP gives sales forecasting and purchase planning, but WMS reduces ship errors and speeds exchange processes in peak seasons.

Verdict: WMS primary; ERP as supporting system.

Scenario: A fashion brand uses Blue Yonder for demand-driven labor planning and integrates with Oracle NetSuite for financials as they expand omnichannel.

Aerospace & Defense

Aerospace warehouses manage serialized high-value components with strict compliance. ERP handles procurement, long-term contracts, and regulatory reporting. WMS must manage serials, shelf-life, and strict parts traceability down to bin and sub-bin level. For defense contractors, audit trails and certificate storage are mandatory.

Verdict: ERP backbone with robust WMS for traceability.

Scenario: An aerospace supplier uses SAP EWM to track serialized components and SAP ERP to manage supplier contracts and compliance audits.

Wholesale Distribution

Distributors move high volumes and require high fill rates. Order accuracy matters for margins. WMS reduces mis-picks and optimizes pallet flows. ERP helps manage supplier purchase orders and credit terms. For distributors, the fastest ROI often comes from WMS automation that reduces labor and errors.

Verdict: WMS-first, ERP for integrated finance.

Scenario: A national wholesaler implements Warego to accelerate pick-to-shipping times, then adds Dynamics 365 to centralize purchase-to-pay processes.

Electronics & High-Turn Consumer Tech

Electronics require fast turnover and serial-level tracking for warranty claims. WMS supports box level traceability, returns handling, and RMA workflows. ERP handles vendor contracts and long-term procurement planning. For consumer electronics, speed in receiving and outbound packing determines customer satisfaction.

Verdict: WMS-focused with ERP integration.

Scenario: An electronics distributor uses Manhattan WMS for serialized inventory control and integrates with NetSuite to reconcile marketplace revenues.

Printing, Packaging & Paper

These industries manage bulky SKUs and need accurate cut-sheet tracking and lot management. WMS optimizes yard and storage, supports bulk pallet management, and streamlines outbound truck loading. ERP supports job costing and supplier management, but WMS improves order fill and reduces loading errors.

Verdict: WMS-first, ERP for costing.

Scenario: A packaging supplier uses Körber for yard and pallet optimization and Epicor for production costing.

Construction Materials & Heavy Equipment

Construction supply chains are long and variable. WMS helps manage yard and indoor storage, tracks heavy parts, and coordinates shipments to job sites. ERP covers project billing and procurement. The warehouse must get the right kits to the right project on time; WMS improves readiness and reduces site delays.

Verdict: WMS for logistics, ERP for project accounting.

Scenario: A supplier uses Infor WMS to manage yard inventory and NetSuite to allocate costs to project codes.

Unify on-hand, reserved, and in-transit stock. Trigger smart replenishment and transfers with fewer surprises and write-offs.

Check Out WareGo WMSERP vs WMS by Business Size

Whether a company should adopt an ERP or WMS often depends on its revenue and operational complexity. Here’s a breakdown of what fits best at each stage of business growth.

Startups & Small Businesses (Revenue <$10M)

Key Challenges:

- Reliance on spreadsheets or low-cost inventory apps.

- Frequent mis-picks, overstocks, and late shipments that eat into margins.

- Limited IT bandwidth to manage heavy systems.

Best-Fit Solution:

A standalone cloud WMS delivers immediate and measurable impact. With fast scanning, simple slotting, and basic task management, businesses see a quick ROI through:

- Reduced labor hours.

- Fewer fulfillment errors.

- Faster order processing.

For online sellers and distribution-focused startups, solutions like Warego or Fishbowl balance low upfront costs with high accuracy and efficiency.

Verdict:

Start lean. Deploy a WMS in one warehouse, standardize picking workflows, and pair it with lightweight accounting or entry-level ERP when revenue growth justifies it. Avoid long, expensive ERP contracts and keep capex minimal.

Mid-Level Companies (Revenue $10M–$100M)

Key Challenges:

- Multiple warehouses and seasonal volume spikes.

- Expanding supplier networks.

- Compliance and reporting pressures.

- Manual reconciliation breaking down across sites.

Best-Fit Solution:

At this stage, a modern WMS is critical for floor-level efficiency:

- Wave picking and barcode accuracy reduce errors.

- Carrier integrations improve outbound fulfillment.

- Labor optimization lowers cost per order.

Meanwhile, ERP systems become essential for:

- Finance and procurement centralization.

- HR and compliance alignment.

- Cross-department governance and reporting.

Verdict:

The sweet spot here is a dual-layer setup — WMS as the operational backbone and cloud ERP (e.g., NetSuite, Dynamics) for financial and regulatory management.

- Begin with WMS to capture immediate operational wins.

- Phase ERP rollout for smoother adoption.

- Budget with KPIs in mind: order cycle time, fulfillment accuracy, and per-order cost.

Scaleups & High-Growth Firms (Revenue $100M–$500M)

Key Challenges:

- Rapid SKU expansion.

- Multi-region fulfillment networks.

- Complex SLAs with retailers and customers.

- High risk of margin erosion due to delays and returns.

Best-Fit Solution:

Both WMS and ERP become non-negotiable:

- WMS: Must support advanced automation (robotics, slotting optimization, orchestration across multiple DCs).

- ERP: Consolidates multi-currency transactions, ensures global compliance, and integrates with CRM/procurement for accurate demand planning.

Verdict:

Scaleups need to invest in both ERP and WMS for survival and scalability. Costs are higher, but the payoff comes through:

- Reduced lead times.

- Lower return rates.

- Improved cash flow visibility.

- Stronger customer retention.

Focus heavily on building a robust integration layer and data engineering pipeline. Converting operational KPIs into financial metrics helps drive smarter decisions around margin preservation and LTV/CAC optimization.

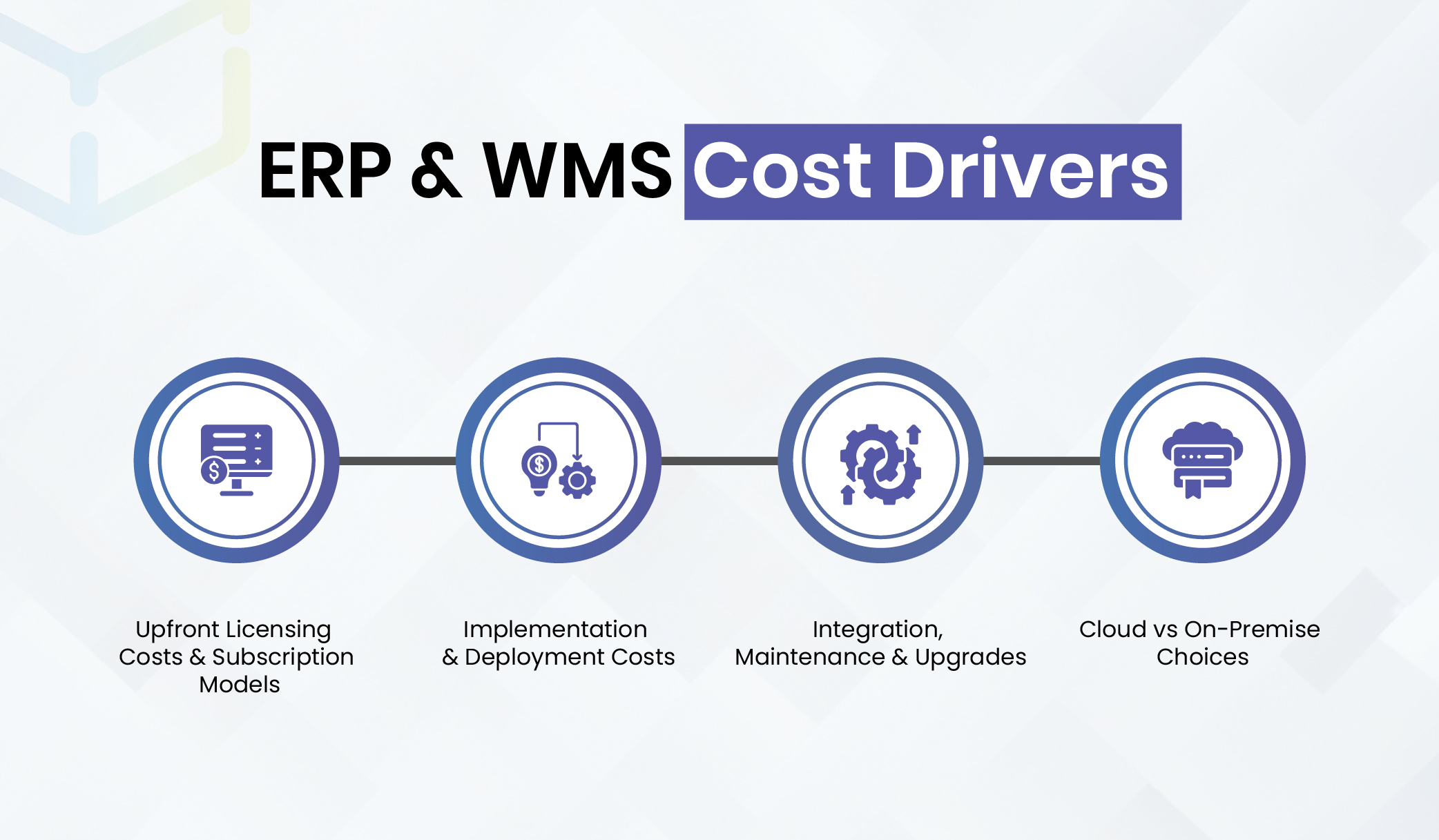

ERP vs WMS Cost Comparison

ERP vs WMS Cost often becomes the tipping point. A system may shine in demos, but if the total ownership cost balloons, it can become a burden rather than a tool. The real comparison isn’t just license fees — you must consider implementation, integration, training, maintenance, and hidden overheads.

Upfront Licensing Costs & Subscription Models

- ERP systems (e.g. SAP, Microsoft Dynamics) typically require large capital or subscription commitments. For enterprise clients, license and subscription fees often range from $50,000 to $500,000+, plus user fees (e.g., $150–$250/month per user).

- WMS solutions, especially modern SaaS ones like Warego, roll out more affordably. Warego’s pricing starts at $449/month for the Standard plan, scaling to $779/month (Pro) and $1,149/month (Advanced) for higher volumes and multiple facilities.

Because Warego is warehouse-specialized, its pricing models are tuned to what warehouse-first businesses need rather than full enterprise modules you may not use.

Implementation & Deployment Costs

ERP implementations are notorious for high overhead. Customization, data migration, cross-department training — these costs can exceed the base license by 2x–3x in some cases.

By contrast, a WMS like Warego is optimized for quicker deployment. Warego’s cloud-native architecture, standard templates, and focus on warehouse operations reduce the “custom build” burden. Many clients can get to baseline operations in weeks, not months, thus reducing consultancy and project risk costs.

Integration, Maintenance & Upgrades

- Integration: To connect WMS with finance, CRM, or ERP modules, you need APIs or middleware. With Warego, some integrations are built-in or easier to configure, reducing custom development overhead.

- Maintenance & support: Annual support contracts typically run 15–20% of license cost. Warego’s subscription model often encompasses ongoing updates, which helps mitigate surprise upgrade costs.

- Training: ERP systems usually demand broader cross-department training, increasing cost and time. WMS interfaces are warehouse-first, making adoption by floor staff faster and lighter.

Cloud vs On-Premise Choices

- Cloud WMS and ERP: Lower upfront hardware cost, smoother updates, and faster deployment.

- On-premise: More control over infrastructure and security, but heavier capital investment and maintenance burden.

Many modern WMS vendors, including Warego, adopt a cloud-first approach, which aligns well with businesses that want to avoid heavy infrastructure investments.

Long-Term Cost Forecast & ROI

- For small to mid-sized warehouse-first businesses, WMS solutions like Warego often cost less over a 3–5 year horizon because the baseline investment is lower, and operational improvements yield faster returns.

- For massive enterprises, ERP may balance out in the long run because unified operations reduce multiple integration layers. But even then, most enterprises adopt a hybrid model (ERP + WMS) to get the best of both worlds.

Example: A distribution business subscribes to Warego’s Standard plan ($449/month). Over 5 years, that’s ~$26,940. Suppose integration and scaling push the total cost to ~$40,000. If they compare that with an ERP implementation costing $250,000 upfront plus annual fees, the WMS-first path delivers value early and keeps overhead manageable.

Direct tasks, live inventory, accurate labor data. Plan confidently and stop reconciling multiple “truths” every afternoon.

Upgrade to WareGo WMSTop ERP & WMS Software in 2025

When evaluating ERP vs WMS, vendor choice shapes warehouse efficiency, cost structures, and scalability. Below are the leading ERP and WMS platforms in 2025, presented with a focus on warehouse relevance, ideal users, and cost signals.

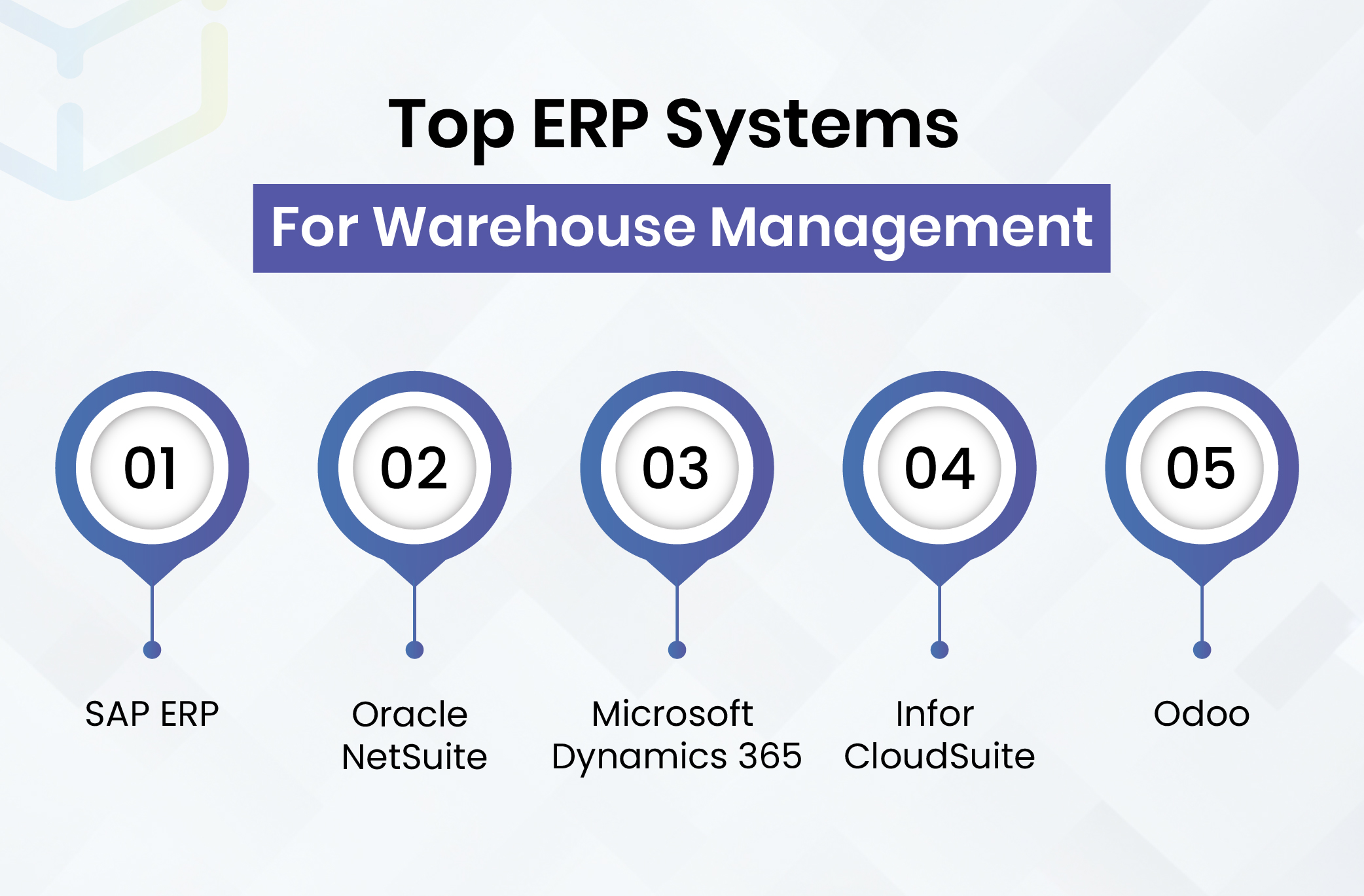

Top ERP Systems for Warehouse Management

SAP ERP

- Warehouse Strength: Extended Warehouse Management (EWM) goes beyond basic inventory. Handles slotting, wave picking, resource scheduling, and integrates with conveyors and PLC automation.

- Best For: Enterprises needing global supply chain control, regulatory traceability, and tight production-warehouse integration. Ideal where warehouses are mission-critical global nodes.

- Cost & Timeline: Expect multi-month rollouts with extensive configuration. Licensing can reach six figures annually for large enterprises.

Oracle NetSuite

- Warehouse Strength: Cloud-native ERP with solid warehousing modules and 3PL integrations. Excels at multi-location inventory, lot/serial tracking, and financial integration.

- Best For: Mid-market eCommerce and distributors seeking fast time-to-value and marketplace/shipping integrations. Often paired with a dedicated WMS for advanced automation.

- Cost & Timeline: Predictable: base subscription + per-user fees. Suitable for mid-market budgets.

Microsoft Dynamics 365

- Warehouse Strength: ERP + supply chain modules with deep Azure and Office 365 integration. Includes order orchestration, workflows, and device management.

- Best For: Mid-to-large companies already invested in Microsoft stack. Offers smooth integrations to automation and advanced WMS when robotics is required.

- Cost & Timeline: Enterprise-level licensing. Pricing depends on modules; full suite requires enterprise budgets.

Infor CloudSuite

- Warehouse Strength: Strong in manufacturing + warehousing. Integrates seamlessly with Infor WMS, supports MRP, and offers broad supply chain visibility.

- Best For: Manufacturers and mid-to-large operations that want ERP + WMS under one ecosystem. Good fit for niche automation use cases.

- Cost & Timeline: Cloud-driven pricing. Varies by scale and customization needs.

Odoo

- Warehouse Strength: Modular and open-source ERP. Inventory module supports multi-warehouse basics, barcoding, routes, and reordering rules.

- Best For: SMBs wanting affordable ERP with customization flexibility. Great entry point before scaling to dedicated WMS.

- Cost & Timeline: Highly competitive. Core apps free in some cases; SaaS deployment charges per module/user.

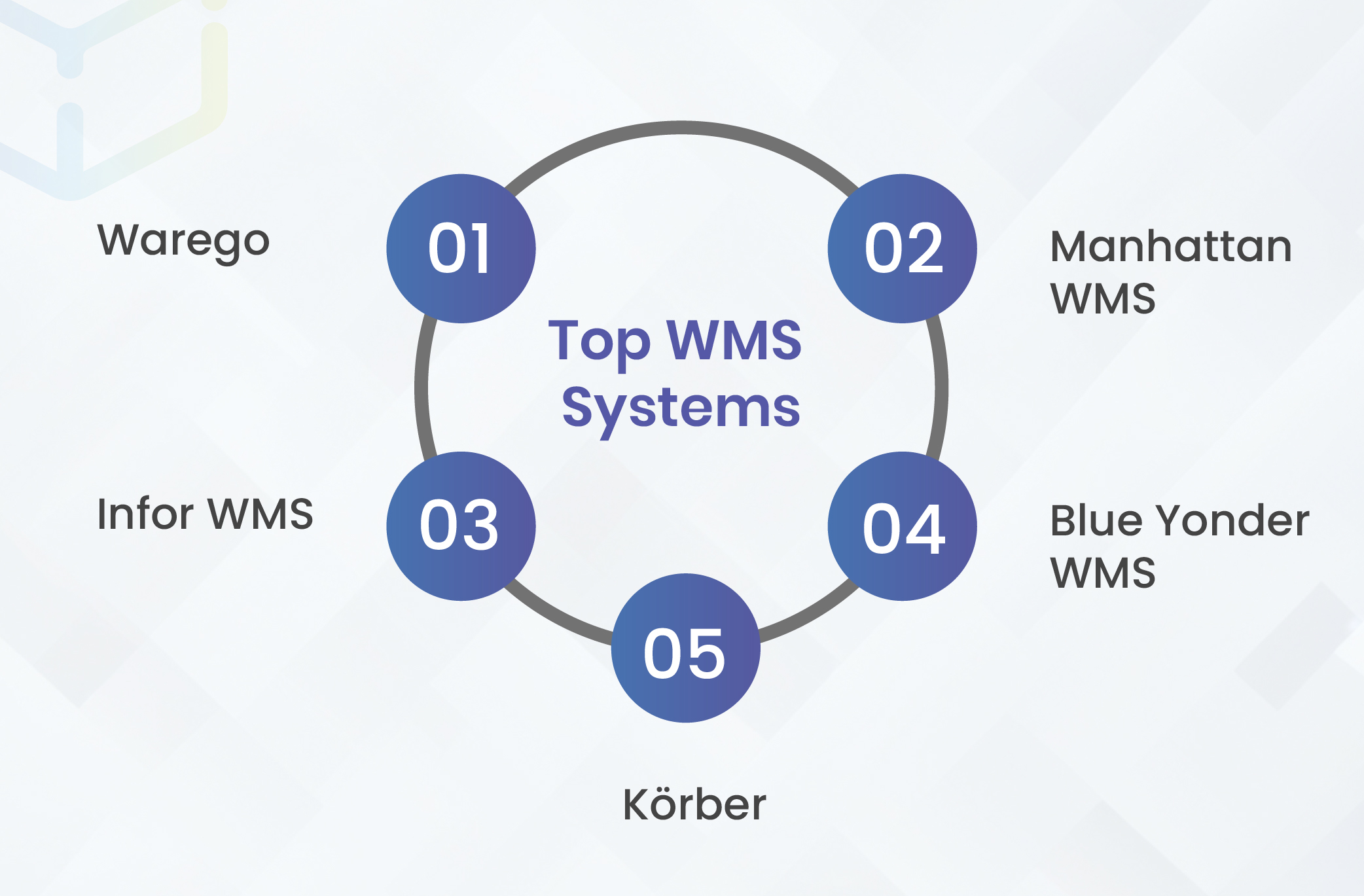

Top WMS Systems

Warego

- Warehouse Strength: Cloud-native WMS purpose-built for real-time inventory tracking, scanning, flexible picking, and ERP integration. Supports automation from handhelds to robotics.

- Best For: SMBs to enterprises seeking fast time-to-value and automation readiness without legacy complexity.

- Cost & Timeline: Competitive entry pricing. Scales with modules and integrations.

Manhattan WMS

- Warehouse Strength: Deep capabilities for complex, automated warehouses. Includes slotting, labor optimization, and robotics integration.

- Best For: High-throughput enterprises (grocers, 3PLs, omni-channel retailers) where downtime isn’t an option.

- Cost & Timeline: High implementation costs. Suited for enterprises making full automation investments.

Infor WMS

- Warehouse Strength: Strong in multi-site fulfillment. Offers wave planning, dock scheduling, directed put-away, and yard management.

- Best For: Mid-size manufacturers and retailers with distributed DCs needing central policies.

- Cost & Timeline: Mid-to-high pricing. Cloud deployment options improve speed and visibility.

Blue Yonder WMS

- Warehouse Strength: Infuses AI and predictive analytics for demand forecasting, labor optimization, and bottleneck reduction.

- Best For: Large-scale retailers and grocers where labor planning and predictive control are major cost drivers.

- Cost & Timeline: Premium pricing. Implementation focuses on long-term optimization vs. quick rollouts.

Körber

- Warehouse Strength: Flexible, industry-adaptive workflows without heavy custom code. Strong for seasonal peaks and 3PL scaling.

- Best For: Companies needing industry-specific configurability and agility in warehouse processes.

- Cost & Timeline: Pricing varies by scope. Strong ROI for dynamic businesses with frequent operational shifts.

ERP Integration with WMS

For many companies, the answer is not ERP or WMS but ERP with WMS. Integration delivers the best of both worlds: deep warehouse functionality connected with enterprise-wide visibility.

Benefits of ERP–WMS Integration

- Unified data flow: Inventory, finance, and procurement data sync in real time.

- Operational efficiency: Warehouse updates automatically reflect in sales and accounting modules.

- Scalability: Businesses expand without worrying about system fragmentation.

- Automation: Streamlined workflows cut manual data entry and errors.

Integration Models

- Native integration – Some ERP vendors like Oracle NetSuite offer WMS modules natively.

- Middleware – Tools like MuleSoft or Dell Boomi bridge ERP and standalone WMS.

- Custom APIs – Tailored integrations for businesses with unique workflows.

Real World Example:

A global apparel retailer uses ERP for procurement and finance but integrates Warego WMS for distribution centers. This ensures warehouse staff have deep functionality while executives still see a unified dashboard.

ERP vs WMS Feature Comparison

Before making a decision, it’s helpful to compare ERP vs WMS features side by side.

Both ERP and WMS support warehouse operations, but the depth and scope of features differ.

| Feature | ERP | WMS |

| Inventory Management | Basic tracking, tied to finance | Advanced, real-time with RFID/barcodes |

| Order Fulfillment | Standard workflows | Wave picking, batch picking, slotting |

| Labor Management | HR module linked | Labor tracking, productivity metrics |

| Supply Chain Visibility | High, across procurement to sales | High, but warehouse-focused |

| Scalability | Multi-entity, multi-country | Limited unless integrated |

| Automation | Limited warehouse automation | Advanced robotics, conveyors, IoT |

Verdict: If warehouse efficiency is mission-critical, WMS shines. For broader business integration, ERP remains unmatched.

Wrap Up

Choosing between ERP vs WMS is less about which is “better” and more about which aligns with your business model, scale, and growth plans. ERP brings integration and scalability, but at a cost and complexity. WMS offers laser-focused warehouse efficiency but requires integrations for enterprise-wide coverage.

For businesses where warehouses are the beating heart of operations, a platform like Warego provides specialized power without the heavy baggage of ERP. For larger companies balancing multiple departments and geographies, ERP systems with strong WMS modules may be the smarter route.

When rules, scale, and multi-site matter, WareGo delivers maturity without bloat. Compare side-by-side before migrating.

Book WareGo DemoFAQs

What is the difference between ERP and WMS?

ERP (Enterprise Resource Planning) manages multiple business functions—finance, HR, sales, procurement, supply chain—within one platform. WMS (Warehouse Management System) is specialized for warehouse operations like inventory tracking, order fulfillment, picking, packing, and real-time stock visibility.

If a company struggles with end-to-end operations like payroll and accounting, ERP is the right choice. But if the main challenge is inventory accuracy and warehouse efficiency, WMS works better. Many businesses integrate ERP and WMS to combine ERP’s strategic visibility with WMS’s operational precision.

Can ERP replace WMS completely?

ERP systems often include warehouse modules, but these usually handle only basic tasks like order entry and stock reconciliation. Businesses needing advanced features—multi-warehouse support, wave picking, barcode scanning, slotting, or real-time analytics—require a dedicated WMS.

A small retailer with one warehouse may manage with ERP alone, but a global eCommerce brand handling thousands of SKUs will find ERP insufficient. In most cases, ERP and WMS integration is the smarter path, balancing financial oversight with warehouse accuracy.

Is ERP more expensive than WMS?

Generally, ERP systems are more costly than WMS because they cover multiple business functions. Platforms like SAP, Oracle NetSuite, or Microsoft Dynamics involve higher licensing, implementation, and maintenance costs. WMS, being specialized, usually offers lower upfront expenses and quicker ROI for warehouse-focused businesses.

Still, long-term needs matter more than upfront costs. For example, a logistics company may start with WMS but later require ERP for finance, HR, and CRM. Investing early in ERP could save duplicated expenses down the line.

Which industries benefit most from WMS?

Industries with heavy inventory turnover or multi-warehouse operations—retail, eCommerce, 3PL, manufacturing, pharmaceuticals, food & beverage—gain the most from WMS.

For instance, an eCommerce brand fulfilling thousands of orders daily benefits from real-time inventory updates and optimized picking. Pharmaceutical firms rely on WMS for batch tracking, expiration monitoring, and compliance. In all cases, WMS reduces errors, speeds fulfillment, and keeps warehouses efficient.

Which industries benefit most from ERP?

ERP fits industries needing visibility across multiple departments, such as manufacturing, healthcare, finance, construction, and wholesale distribution. Unlike WMS, it unifies financials, HR, procurement, and CRM into one system.

For example, manufacturers use ERP to connect production schedules with raw materials and customer orders. Healthcare providers rely on ERP for procurement, billing, and compliance. Any sector requiring cross-departmental collaboration benefits from ERP’s broad scope.

Should small businesses choose ERP or WMS?

For small businesses, the choice depends on priorities. If the goal is managing finances, invoicing, and procurement alongside basic inventory, ERP offers more value and long-term scalability.

But if efficiency in warehousing is the main challenge—such as in eCommerce startups or wholesalers handling large SKUs—WMS is a practical, cost-effective choice. Many small companies start with WMS, then integrate ERP as they grow.

Can ERP and WMS work together?

Yes. ERP handles planning, HR, and compliance, while WMS drives fulfillment and inventory accuracy. Integrated, they provide seamless data flow and eliminate silos.

For example, an order placed in ERP syncs with WMS for picking and shipping. Once fulfilled, WMS updates stock, which ERP uses for forecasting and reconciliation. This integration reduces errors, boosts efficiency, and improves customer satisfaction.

What are the risks of choosing the wrong system?

Choosing incorrectly can lead to inefficiencies and wasted investment. Using ERP when only warehouse efficiency is needed results in underutilized features, while relying solely on WMS when finance and CRM are critical limits growth.

There’s also a risk of poor adoption if the system doesn’t align with business needs. To avoid this, companies should assess requirements carefully and work with experienced ERP or WMS providers.

How do ERP and WMS impact customer experience?

WMS directly improves customer experience by reducing order errors, updating stock in real time, and speeding deliveries. For example, eCommerce businesses using WMS face fewer “out of stock” issues and deliver faster.

ERP improves customer service indirectly through smooth billing, sales order management, and after-sales support. Together, ERP and WMS deliver both operational speed and back-office accuracy, boosting customer trust and retention.