In recent years, extreme climate changes, inflation, geopolitical volatility, and the pandemic have profoundly affected the global supply chain.

Reports confirm that 84% of supply chain leaders have adjusted their business strategies in response to the pandemic.

Still, after changing strategies, supply chain issues remain to date. Despite the global economy’s struggles, localized shortages persist, and as the population continues to grow, the situation worsens.

Inflation, labor shortages, and congestion affected the supply chain in ways no one expected. This is why warehouse management software is becoming the backbone of supply chain resilience.

In this blog, we will delve deeper into supply chain challenges, industry-specific strategies for overcoming them, and how to modernize growth and development through effective supply chain operations.

WareGo is here to help you with your supply chain issues

Connect Now!Table of Contents

Supply Chain Issues Timeline 2021-2025: A Roadmap From Crisis to Modern

Before we begin, it is essential to understand the history of supply chain management and the origins of the issues in this field.

Let’s begin with the timeline and key challenges.

| Timeline | Key Challenges | Impact on Supply Chain | How can companies survive? |

| 2021 to 2022 |

| These challenges slowed down manufacturing, with no interaction with laborers and no deliveries. |

|

| 2023 to 2025 |

| These challenges resulted in increased international freight times, additional shipping costs, and various global sourcing issues. |

|

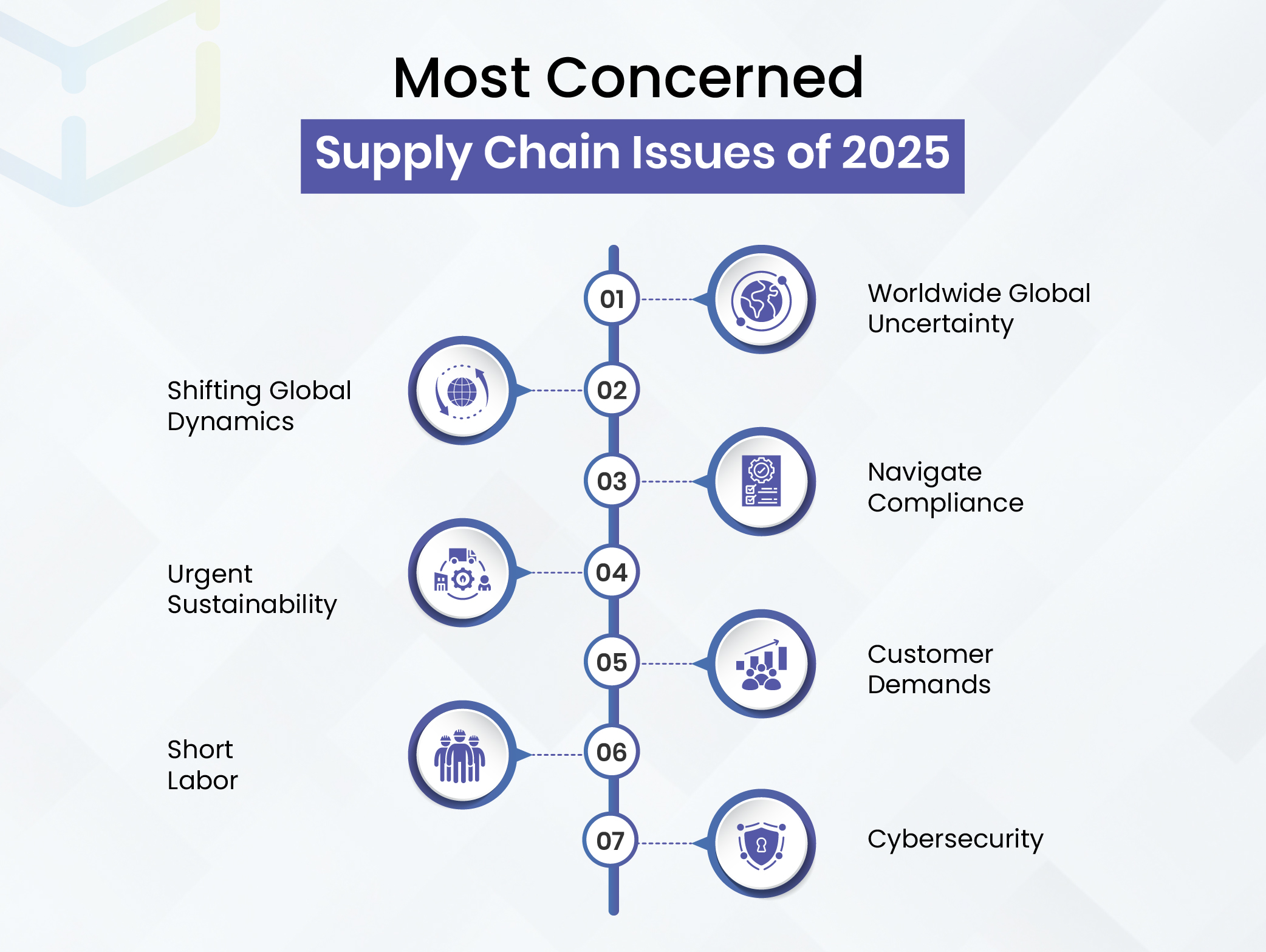

Most Concerned Supply Chain Issues Of 2025

As we enter 2025, businesses and supply chain experts are facing unheard-of and out-of-the-box challenges to overcome. These challenges are impacting the overall growth, productivity, and profitability.

Let’s see those challenges in detail:

1. Worldwide Global Uncertainty

Global supply chain issues are becoming increasingly significant, presenting complex challenges across various industries.

Global uncertainty has multiple causes, including fluctuating oil prices, rising inflation rates, and shifts in trade policies.

These forces disrupt cost structures and operational stability worldwide. To enhance and stay ahead of these forces, use advanced technologies like

- Financial forecasting tools.

- Predictive supply chain analytics.

These technologies will help you anticipate uncertainties before you escalate in the process.

2. Shifting Global Dynamics

Global shifts influence supply chain problems, particularly with the return of Donald Trump in 2025. It’s time for businesses to remain vigilant and informed about global foreign affairs.

Combine your firms into technological and strategic partnerships to maintain resilience, enhance supply chain strategies, and navigate long-term geographical landscapes.

To stay informed, you can:

- Focus on potential flaws in trade policies.

- Maintain a strong relationship with global partners.

Being in the supply chain industry, it’s essential to maintain neutrality and focus on strategic adjustments. This can be achieved by utilizing strong tools like warehouse management software.

3. Navigate Compliance

Automotive supply chain issues, while navigating the web of local and global regulations across the market, are one of the most pressing challenges for all supply chain leaders.

Maintaining clarity within teams, while implementing it into more supply chain workflows, will help you structure documentation and have a smoother experience as well.

It all starts with trade restrictions and ends with safety standards; this complexity has become an easy burden for many.

Opting for an automated system can help you with:

- Track and manage compliance data.

- Stay informed about regulatory changes and integrate them into your business.

Collaboration and automation will help you work efficiently through actionable steps to adopt and update systems.

4. Urgent Sustainability

Issues in supply chain management have shifted from deep-seated strategies to an immediate priority, focusing on sustainability.

Companies are now under intense pressure to demonstrate their logistics practices to meet border ESG (environmental, social, and governance) goals and objectives.

How can you achieve these objectives:

- Optimize transportation to cut fuel consumption.

- Invest more in renewable energies while reducing overall energy consumption.

This can help your business achieve more regulatory compliance and meet the rising expectations of both consumers and investors.

5. Customer Demands

Modern customers expect more than just a faster service. Not only that, but they also demand more transparency, personalization, and customization.

Meeting their expectations in 2025 requires more advanced analytics to understand and anticipate consumer behaviors, enabling businesses to manage inventories more effectively and minimize waste.

Supply chain leaders should adopt these technologies:

- Offer real-time tracking.

- Give end-to-end transparency with personalized delivery options.

Companies need to integrate responsive solutions, not just to address current customers’ demands, but also to focus more on future market trends and innovation.

6. Short Labor

Persistent labor shortage, especially when it comes to warehouse workers and transport drivers. These shortages are prompting companies to reassess their workflow strategies.

Automation is becoming increasingly important in bridging the gaps and enhancing productivity. Still, technology is not enough; retaining and maintaining a disciplined workforce is a vital form of supply chain business.

You must prioritise:

- Adapt employee retention softwares.

- Invest more in in-workforce development.

A stronger focus on capital strategies can create a workplace where employees are equipped to meet both current and future pressures and challenges.

7. Cyber-security

As supply chain security issues become increasingly digitalized, the risk of cyber threats continues to grow. A single security breach can disrupt operations, compromising sensitive data and damaging the company’s reputation.

Focus on regular audits, and employee training is essential to ensure that they collaborate with IT security that knows how to be defensive against emerging threats.

You can safeguard against these risks:

- Invest more in cutting-edge cybersecurity measures.

- Subscribe to secure VPNS or real-time monitoring systems.

Combine your technology with security that helps companies safeguard both their digital infrastructure and operational continuity.

Trust us to save your business efficiently.

Request a Free Demo!How to Overcome Supply Chain Issues

Supply chain issues are persistent and unlikely to subside anytime soon. As you operate in a competitive supply chain market, you must focus on meeting customer demands and leveraging technological solutions to stay ahead of the competition.

Additionally, businesses can now more easily reduce risks and build resilience by adopting the right strategies.

Gartner predicted that managing risk will help companies achieve successful risk drivers, up to 50% in 2025.

Supply chain management has no fixed and constant strategies that can help brands overcome their challenges.

However, there are a few strategies you should consider that can help you empower your enterprise to overcome all these challenges, driving growth and revenue.

The strategies to overcome supply chain challenges begin here!

Resilience Supply Chain

The foremost strategy for any supply chain leader is to focus on resilient and logistics environments. This will allow businessess flexibility and adaptation to sudden disruptions.

Develop more effective approaches to address inventory control challenges or market fluctuations. Not only that, but also embrace strategic planning and bring flexibility to secure financial resources, such as credit lines, to stay agile and meet customer demands.

This shift can help firms to enable businesses to navigate uncertainties with confidence. Additionally, a robust resilience framework minimizes risk and facilitates long-term growth, even in the face of unexpected disruptions.

Advance Supply Chain Technology

Upgrade your business into the tech and artificial intelligence market. Adopt cutting-edge supply chain technologies and all other Internet of Things (IoT) to streamline operations.

Focus more on predictive analysis and demand forecasting to optimize inventory levels. Meet all expectations and allocate resources more effectively to help reduce costs and enhance decision-making across all supply chain channels.

All this can happen if you invest in robust software solutions, such as real-time inventory tracking, route automation, and integrated warehouse management systems (WMS). Additionally, combining these technologies can provide flexibility and pave the way for future success.

Supply Chain Cybersecurity

Cybersecurity in supply chain management is way more important than it seems. In today’s digital economy world, where cyber threat rates are on the rise, it’s essential to protect digital infrastructure.

Develop strategies to implement cybersecurity measures, including firewalls, authentication, and encrypted data storage. Also, build a strong team with well-defined training to implement security measures accurately and without errors.

By strengthening your cybersecurity measures, you are not only protecting all supply chain operations but also building a more secure supply chain that everyone can rely on.

Diversify Supply Chain Sourcing

Diversify your operations; do not put all your eggs in one basket. Relying on a single fulfillment partner or supplier can affect the business with vulnerable disruptions.

Diversifying your supply chain sourcing or fulfillment operations helps minimize the risk created by geopolitical tensions, trade policy changes, raw material shortages, and longer development or procurement lead times.

Cultivate strong partnerships both locally and globally, and it’s better to combine third-party providers (3PLs) for improved flexibility and effectiveness in your supply chain. A diversified supply chain strategy enhances adaptability and positions the business to thrive in changing market conditions.

Supply Chain Liquidity

Protect your business with flexible access to capital. After all, the meeting service level on hand is often the difference between success and failure.

Liquidity often determines which company can successfully navigate disruptions. Customers’ demands and inventory needs fluctuate regularly. That leads enterprises to create a line of credit or other financing options to provide the exact cash flow that is needed to stay ahead.

A wise business owner must focus on capital to stock high-demand products, as well as manufacturing or shipping to cover freight when needed.

Build up Supply Chain Management with WareGo

In today’s rapidly evolving digital global market, supply chain issues persist year after year. Yet, businesses need resilience and competitiveness to transform and manage supply chain challenges.

Since the pandemic, the urgent need for greater supply chain optimization, faster decision-making, and the pressure to satisfy customers have driven significant changes in data. To overcome these challenges, technology has been the savior for all supply chain leaders.

With WareGo, you can go beyond software. We focus on helping you create a hub with technology and e-commerce warehouses. Before it’s too late, collaborate more effectively to create streamlined operations and lasting partnerships. It’s time to empower your business to become more resilient and ready for the future.

Partner with WareGo today and see the best results in the future.

Book Us Now!Frequently Asked Questions- FAQS

What are supply chain issues?

The supply chain issues are:

- Worldwide Global Uncertainty

- Shifting Global Dynamics

- Navigate Compliance

- Urgent Sustainability

- Customer Demands

- Short Labor

- Cybersecurity

What is the key issue in supply chain management?

The primary key issues in supply chain management can be:

- Resilience

- Cost

- Speed

- Reliablity

- Supplier delays

- Global uncertainties

What are the seven different types of supply chain risks?

Seven Different types of supply chain risk are:

- Operational risk.

- Financial risk.

- Environmental risk.

- Geopolitical risk.

- Supply risk.

- Cybersecurity risk.

- Demand risk.