Warehouses are under pressure from multi-channel orders, tight SLAs, and shifting demand. You don’t need hype but a clear way to cut errors, speed up picks, and keep stock honest. That’s where the right warehouse management software (WMS) earns its keep.

This guide focuses on what actually makes warehouse operations more efficient. The answer is a reliable WMS with real-time visibility, cleaner receiving and put-away, smarter slotting, faster picking and packing, and solid returns control.

Let’s break down the top 10 must-have WMS features businesses should prioritize, how they work together day-to-day, and a simple way to shortlist vendors without overrunning timelines or budgets.

Table of Contents

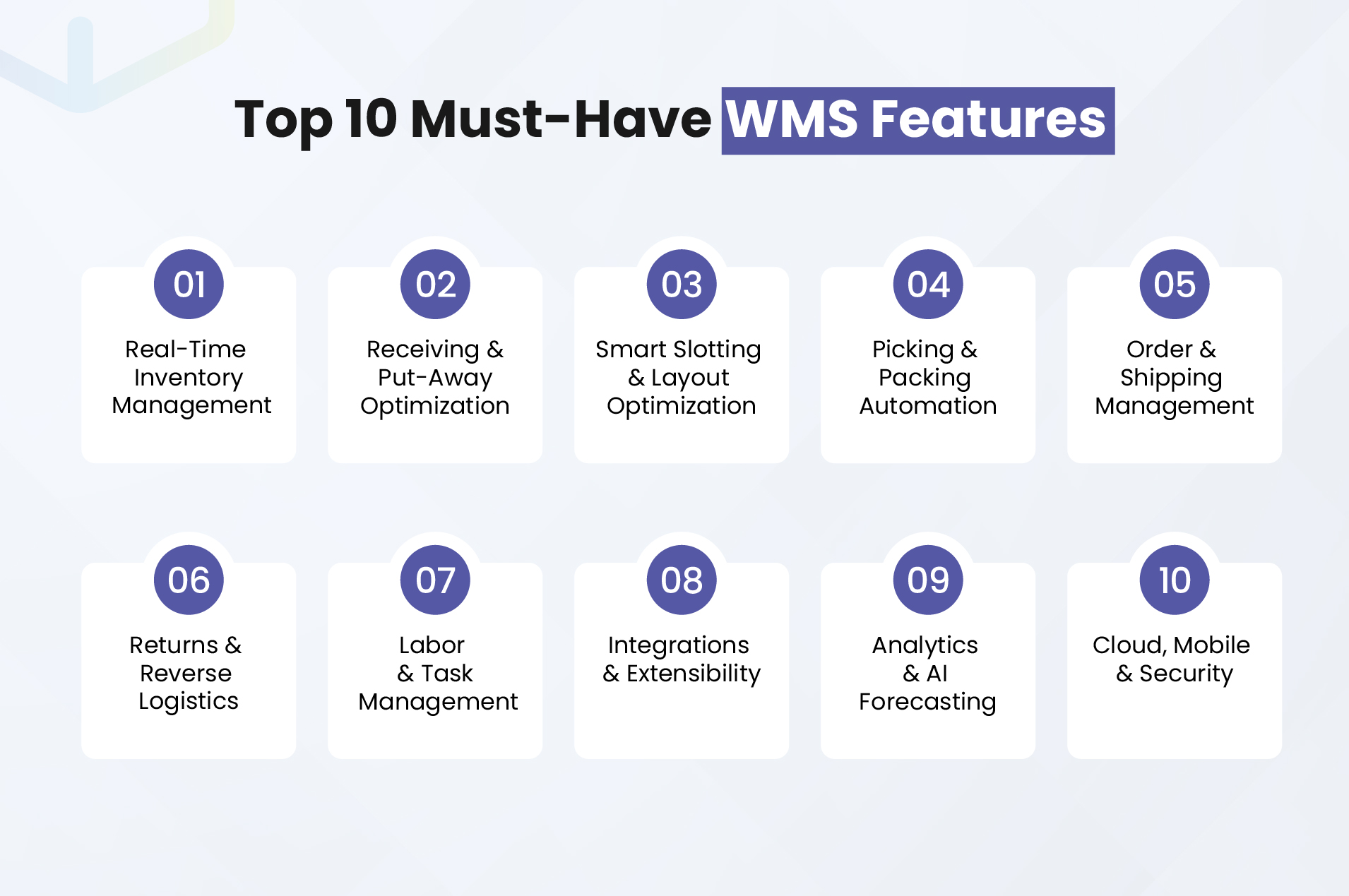

Top 10 Must-Have WMS Features

Use this list of top warehouse management system features to cut errors, speed fulfillment, and keep inventory transparent across shifts. Here’re the practical capabilities teams actually look for in a WMS.

If you are new to warehouse management, start with our beginners’ guide, then use this checklist to scope your pilot now.

1. Real-Time Inventory Visibility & Cycle Counting

Accurate stock insights starts with perpetual tracking at the bin, lot, and serial level. Barcode and RFID capture confirm movements at receipt, put-away, picks, and transfers, which reduces blind spots. Exception logic flags mismatches between system and physical counts, so teams prevent stockouts and wasted travel before orders stall.

Automated cycle counts replace disruptive physical inventories. You set count classes, thresholds, and triggers by velocity or value. Targeted recounts lift pick accuracy, reduce rework at pack, and help maintain service levels during peaks without pulling labor off live orders.

- Perpetual inventory by bin, lot, and serial

- Barcode and RFID capture on every move

- Variance thresholds and exception alerts

- Cycle count scheduling by ABC class or triggers

- Complete audit trails for reconciliation

2. Receiving & Put-Away Optimization (ASNs to First Pick)

Inbound speed sets the pace for the day. Advanced Shipment Notices load item, quantity, and lot data before the truck arrives. Dock calendars level arrivals. Blind receiving handles unplanned deliveries without losing traceability. Teams stage large receipts, capture serials and lots, and route QC holds without blocking other bays.

Suggested put-away uses rules for velocity, cube, weight, hazard class, and temperature. The system directs operators to the best slot and confirms with scans. Faster dock-to-stock time, cleaner traceability, and earlier allocation to open orders follow.

- ASN import with dock appointment scheduling

- Staged receipts, blind receiving, and QC routing

- Serial and lot capture with label validation

- Rules-based suggested put-away by velocity and cube

- FEFO and FIFO assignment at receipt

3. Smart Slotting & Layout Optimization

Good slotting reduces travel, touches, and strain. Heat-map and velocity data drive placement so fast movers sit near pick and pack while oversized or slow items sit deeper. The system evaluates storage media, pick-face depth, and replenishment frequency to minimize touches.

Rules consider case size, weight, breakability, temperature zones, and ergonomic reach ranges. Seasonal re-slotting plans handle promotions and demand spikes. Congestion warnings help you reroute flows when aisles back up.

- Velocity and heat-map insights for placement

- Travel minimization and replenishment rules

- Ergonomic and safety constraints in slotting

- Seasonal re-slotting scenarios with preview

- Congestion detection and reroute suggestions

4. Picking & Packing Automation

Pick methods should match order mix. The WMS supports batch, cluster, wave, zone, or serpentine so supervisors can balance work across zones and times. Scan-to-confirm steps at item and location reduce mispicks. Interleaving replenishment with picks keeps pick faces stocked without extra trips.

At pack, cartonization selects the right box based on dimensions and weight. Scans double-verify item and quantity. Paperwork generates automatically and integrates with scales and dimensioners, so labels, customs docs, and manifests are accurate the first time.

- Multiple pick methods selectable by profile

- Pick-to-cart or tote with scan confirmation

- Cartonization with cube and weight checks

- Pack verification with document generation

- Instant label, manifest, and export paperwork

See receiving, picks, pack, and returns on live data. Bring problem orders and edge cases to test.

Book Live Demo5. Order Orchestration & Shipping Management

Bring all channels into one queue with consistent statuses. Allocation rules consider inventory availability, backorders, splits, and promised ship dates. Available-to-Promise checks protect commitments and route orders to the best node.

Carrier selection weighs service level, cost, zone, and dimensional weight. Labels and tracking events post back automatically, so customer updates are timely and support stops chasing shipments.

- Omni-channel order capture and unified statuses

- Backorder, split, and partial-ship logic

- Available-to-Promise and node selection rules

- Carrier rate shopping and service constraints

- Automatic label and tracking event updates

6. Returns & Reverse Logistics

Returns are unavoidable. A solid RMA process captures reason codes, order links, and expected conditions at initiation. At receiving, guided steps record photos, perform tests, and assign a disposition without rekeying.

The system enforces rules for restock, refurbish, quarantine, or scrap. Fraud controls check for repeat abuse. Refunds and exchanges post automatically when items pass inspection. Clear data flows back to merchandising and quality to reduce future returns.

- RMA creation with reason capture and order link

- Guided inspection with image evidence

- Disposition rules for restock, refurbish, quarantine, scrap

- Fraud safeguards and approval thresholds

- Automated refund or exchange workflows

7. Labor & Task Management

Direct work to the next best task based on priority, proximity, and skill. The WMS sets engineered standards, tracks units per hour, and highlights dwell time in queues. Supervisors can rebalance loads across pick lines and shifts within minutes.

Dashboards surface blockers, such as missing replenishment or congested aisles, so teams resolve causes rather than push backlog forward. Incentive programs tie payouts to clean metrics, which increases throughput without adding headcount.

- Dynamic assignment with proximity and skill matching

- Priority and SLA cues across tasks

- Productivity and dwell time metrics by worker and zone

- Overload and fatigue alerts with shift views

- Incentive scorecards aligned to standards

8. Integrations & Extensibility (ERP/CRM/TMS/Marketplace)

Data should move without copy-paste. Prebuilt connectors reduce setup time for ERP, CRM, TMS, and marketplaces. Open APIs and webhooks handle edge cases and custom flows. Robust error handling gives clear retries, quarantines, and alerts, so teams resolve issues fast.

A master-data strategy for SKUs, units of measure, locations, and reasons prevents mismatches. Event streams feed BI tools and data lakes for deeper analysis without manual exports.

- Prebuilt connectors for core business systems

- Open APIs and webhooks for custom needs

- Idempotent calls and clear error handling

- SKU and UOM governance with validation

- Real-time event feeds into BI and lakes

9. Analytics & AI Forecasting

Real-time dashboards track pick accuracy, lines per hour, dock turns, OTIF, and return rates. Trend views reveal drift before customers feel it. Alerts notify when KPIs cross thresholds, so supervisors react early.

AI models forecast demand and labor by day and shift. The system recommends actions such as re-slotting specific SKUs, pulling forward replenishment, or changing pick methods for a batch. This shifts teams from reactive firefighting to planned adjustments.

- Live KPIs with drill-downs to order and worker

- Trend and anomaly alerts with thresholds

- Demand and labor forecasts by shift and zone

- Prescriptive task suggestions tied to impact

- Self-serve reports for operations and finance

10. Cloud, Mobile & Security

Mobile scanning and tablet workflows keep work moving on the floor and in the yard. Offline protection buffers scans during short network drops and syncs when stable. Cloud deployment simplifies updates, improves uptime, and provides backups with defined recovery points and objectives.

Security controls protect data and access. Role-based permissions limit what each profile can do. Single sign-on and MFA reduce credential risk. Encryption in transit and at rest, plus immutable audit logs, support regulatory and customer requirements.

- Mobile tasks with offline queueing and sync

- Cloud resilience with backups and recovery targets

- Role-based access, single sign-on, and MFA

- Encryption in transit and at rest

- Immutable audit logs for compliance and forensics

Map integrations, devices, and reporting needs. Leave with a realistic timeline, risks, and success metrics.

Request ConsultationHow to Choose the Right WMS

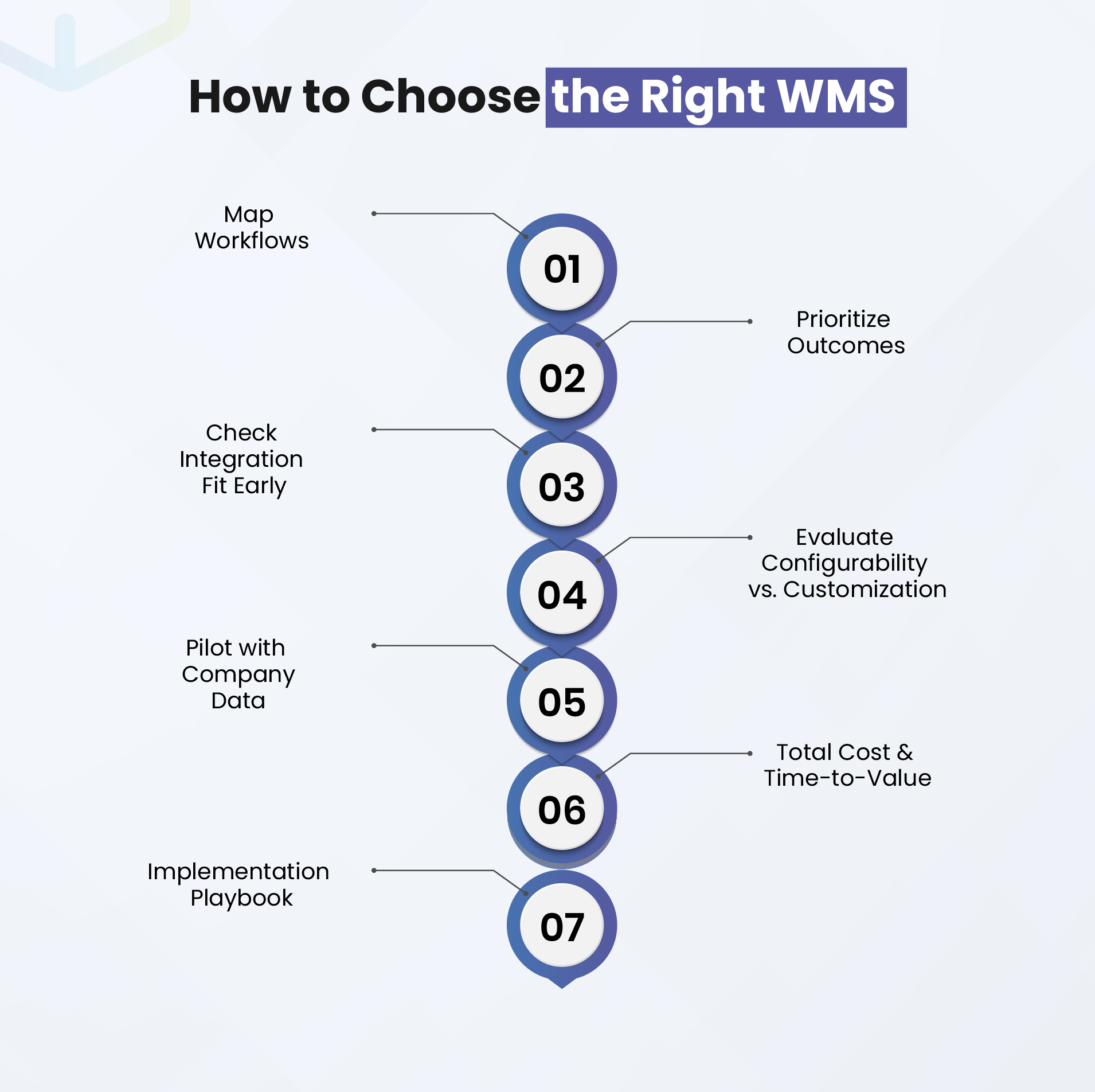

Pick a modern WMS by starting with your workflows, not features. Validate integrations, data accuracy, and reporting. Run a pilot, measure outcomes, and choose the system that improves operations fastest.

Map Real Workflows Before Features

Document inbound to returns as it actually runs. Capture volumes by SKU and order type, peaks, constraints, service levels, and error hotspots. With that reality, you can test only features that remove clear bottlenecks.

Prioritize Outcomes

Rank requirements by impact on accuracy, throughput, labor hours, OTIF, freight cost, and compliance. Map each priority to two features you will verify in a pilot, with target metrics and acceptable variance ranges.

Check Integration Fit Early

List ERP, OMS, TMS, marketplaces, finance, and BI. Confirm prebuilt connectors, authentication, and data scopes. Ask for a live demo of failure handling, retries, and reconciliation so bad data does not stall orders.

Evaluate Configurability vs. Customization

Prefer rule engines, editable workflows, and page builders over custom code. Check how quickly teams can add locations, change pick rules, or update labels. Measure time and steps, not screenshots in a slide deck.

Pilot with Company Data

Run a sandbox on real SKUs, units, orders, and return reasons. Track pick accuracy, lines per hour, dock-to-stock time, exception closure time, and inventory variance. Keep scope tight, then scale the pilot across one zone.

Total Cost & Time-to-Value

Model WMS cost beyond licenses. Include devices, implementation services, internal labor, change management, and ongoing administration. Compare time to the first live site and payback period. Challenge “all-in” bundles and per-scan fees in contracts.

Implementation Playbook

Ask for a detailed WMS implementation plan. Look for phased rollout, data migration steps, super-user training, and parallel runs with success criteria. Clarify partner responsibilities, escalation paths, SLAs, and who owns change requests after go live.

Walk through your inbound, storage, and shipping flows. Get a clear plan for quick wins and phased rollout.

Schedule CallPick a WMS Built for Busy Weeks

Selecting a WMS is a performance decision, not a software purchase. Anchor on measurable outcomes, verify workflows in a pilot, and commit to continuous tuning. The right platform will shorten paths, surface exceptions early, and give your team clear levers to protect service levels every day.

WareGo fits small to mid-sized growing operations that need speed, accuracy, and simple control. You get modern essentials out of the box, fast onboarding, clean integrations, and mobile-first execution. The result is higher productivity with efficient labor use and reliable, day-to-day predictability.

FAQs

What does a WMS actually replace in daily work?

It replaces manual counts, disconnected spreadsheets, and ad hoc shipping tools with standardized receiving, put-away, picking, packing, and returns flows. Teams get one source of truth for stock and orders, fewer errors at pack, and faster, more predictable dispatch.

How long does WMS implementation usually take?

Timelines vary by scope. A focused single-site pilot with standard features can go live in weeks. Multi-site rollouts with data cleanup, integrations, devices, and change management can take months. Plan phased milestones, success criteria, and hands-on super-user training.

What drives WMS cost beyond licenses?

Budget for scanners and tablets, setup and integration services, internal project time, training, label media, and ongoing admin. Include carrier accounts, BI connections, and support tiers. Model payback from gains in accuracy, lines per hour, dock-to-stock time, and fewer chargebacks.

How long should a WMS pilot run, and what should I measure?

Run four to six weeks in a single zone. Track pick accuracy, lines per hour, dock-to-stock time, inventory variance, exception closure time, and return cycle time. Set target ranges up front and expand only after meeting them consistently.

Which WMS features should I prioritize first?

Start with real-time inventory accuracy, receiving and put-away optimization, slotting, multi-method picking, and returns control. These reduce errors and travel, stabilize throughput, and protect OTIF. Add analytics, integrations, and labor management once core flows are consistent and measurable.