When every vendor claims to offer the best wms cost and features, evaluating which to choose becomes difficult.

Therefore, cut to the chase with our how to choose a warehouse management system guide of 2025 and learn what boxes pros like Walmart, Alibaba, and HP checked when choosing a WMS for their business.

Table of Contents

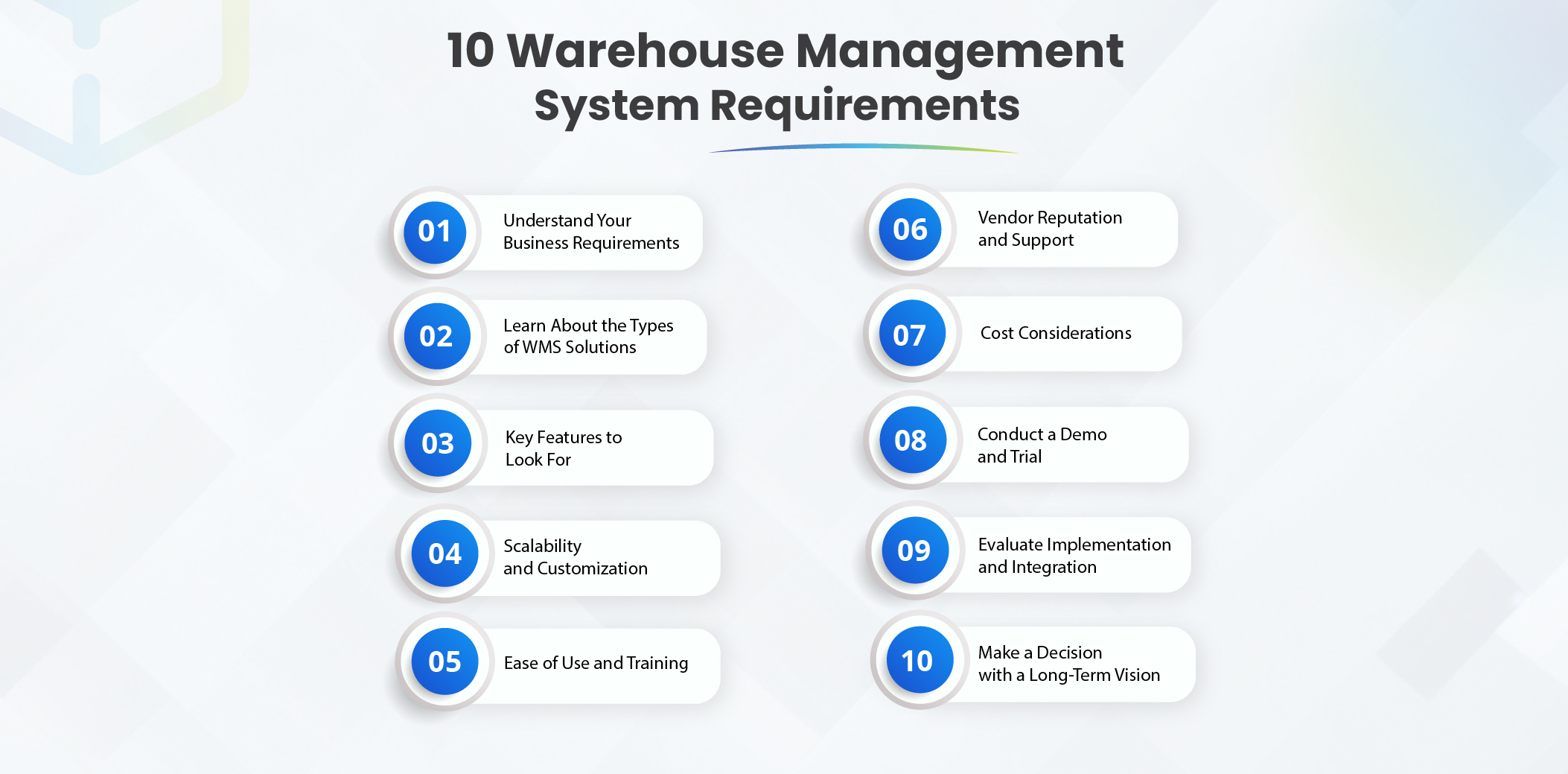

Key WMS Requirements to Consider Before You Buy

A WMS, abbreviation of warehouse system, that allows businesses to manage, optimize, and automate warehouse operations. A warehouse management software gets this all done from a single dashboard, be it inventory tracking, order fulfillment, resource management, space allocation, or more. However, not every WMS software has the same features; therefore, consider the following wms requirements to ensure you pick the right one for your business.

Selecting the right warehouse management system is difficult. To ease our clients' situation, we developed WareGo WMS, which is scalable and intuitive and offers end-to-end integration with all systems. Streamline your operations from day one!

Start a free Demo1. Understand Your Business Requirements

The first confusion that decision makers face while choosing a WMS is that every vendor says their solution is the best, and picking the one becomes difficult. Thus, instead of taking their word for their solution, decide by understanding your business and what it requires to make the operations efficient.

If you already have a WMS implemented and you are seeking a switch from one solution to a better one, this step can be easy. Simply list the features missing in your current WMS and make sure to check whether they are present in a WMS you are about to choose.

Nonetheless, if you are choosing a WMS for the first time, ensure you take the following steps.

- Go through the processes of your warehouse. What operations do you need to automate, and what features can add efficiency to your business processes? Once done with that, list all you understand on paper or a notepad for the decision-making step.

- Carry out an identification process where you check your warehouse processes’ pain points and inefficiencies. For instance, manual data entry, inaccurate reporting, or missing inventory. Knowing the gaps lets you pick a WMS that covers them for your business.

- Once gaps are identified, define clear goals. For example, if you want to reduce picking errors, improve inventory accuracy, or support growth, these are your goals, and you need to pick a WMS that helps you achieve them.

- Consider the size and complexity of your warehouse. If your business deals with large-scale operations, most WMSs do not work for them, and you need to consider one specifically made for complex operations.

2. Learn About the Types of WMS Solutions

There are several types of WMS solutions in the market. Learning each of them is essential to know what works best for your business. Some common types include:

- Standalone WMS: Unlike other types of WMS solutions, standalone WMS is a type that is designed only to manage and automate warehouse operations. This type of WMS is usually cost-effective, easy to use, and best for small businesses. However, this WMS usually comes with limited functionality.

- Integrated with ERP: This WMS is a warehouse management functionality integrated with an enterprise resource planning (ERP) system. Thanks to its integration with the ERP system, it helps enhance data accuracy, improve inventory management, and streamline supply chain management. However, the downside is that it is complex and might cost a fortune.

- Cloud-Based WMS: A cloud-based WMS, like WareGo, is a software application hosted on the internet. It offers solutions like managing and controlling warehouse operations and inventory without implementing a WMS onsite. This WMS type is easy to scale as the business grows, offers convenient accessibility, and provides top-notch cybersecurity. But a drawback is that you need to have a high-quality internet connection to leverage this solution.

- On-Premise WMS: An on-premises WMS is a software solution that a business installs and manages on its own servers and hardware within the company’s physical location. This WMS allows clients complete control, customization authority, and independence. On the other hand, cons include maintenance responsibilities and a higher price tag.

When you are done with WMS Types, check the best software for warehouse management to make a decision.

3. Key Features to Look For

As discussed above, not all WMS features are the same. Some WMS software applications offer some features while lacking others, and vice versa. However, there are certain features that must be present in a WMS software to help your business operations become efficient and effective. This is an important point of the wms functional requirements.

- Real-time inventory tracking

- Order management

- Barcode/RFID scanning

- Receiving and put-away

- Picking and packing

- Shipping integration

- Reporting and analytics

- Mobile accessibility

- Integration with other systems (ERP, TMS, ecommerce, etc.)

Why stitch together tools when one platform can do it all? WareGo includes real-time inventory tracking, seamless ERP integrations, and more. All in a user-friendly interface, your team will actually enjoy using.

View Pricing4. Scalability and Customization

Since every business is different, finding a perfect match made in heaven kind of WMS is not possible, and that is where the requirement of scalability and customization comes in. It is vital to ask the vendor: “Can this WMS grow with my business?”

Check for customization options and see if your team can tailor the software to meet your business’s unique workflows. If not, keep the expense in mind that you will need to pay an external group of developers to customize the system.

Other than customization, evaluate if your software offers multi-warehouse and multi-location support so that you will be all set when your operations, inventory, and processes go.

5. Ease of Use and Training

Usage and training of a cold storage WMS is as important as taking a brilliant WMS onboard. Whichever retail warehouse management system you choose, ensure it offers a memorable user experience and that its user interface is easy to understand and intuitive.

If your warehouse staff is dealing with the software for the first time, make sure the learning curve is not steep, so that your team becomes efficient with the software in no time.

Another important feature to look for is multi-language support, so no matter which background or region your team is coming from, they can use the software easily.

6. Vendor Reputation and Support

Some business owners make the mistake of investing in a 3pl WMS software by looking at the price tag. However, an affordable or expensive price tag does not showcase the credibility of the wms vendor. Therefore, before you make the final decision on the solution, check the vendor’s reputation and the support they offer.

- Carry out a thorough analysis of the vendor’s history and reputation. You can do this by checking the vendor’s website, the testimonials mentioned on the website, or even word of mouth.

- Search for reviews and case studies as they are often available online for free. However, instead of reading the top reviews, understand customers’ overall experience with the vendor.

- Look out for the implementation services and support they offer with the software once implemented. Also, discuss implementation costs, as most vendors charge a separate fee for implementation and post-implementation support.

- Ask the clients about service level agreements (SLAs) to make sure your service expectations and the vendor’s delivery obligations are clear.

7. Cost Considerations

Cost considerations are among the most important points of wms requirements. Begin by evaluating your budget as to how much you are willing to spend to automate your operations and what costs or packages are offered by the vendors in the market.

- While taking price quotes from the vendors, ask about the upfront costs and if there are any ongoing charges. This is an important consideration as most vendors have separate prices for subscription, licenses, maintenance, etc.

- Then, there are hidden costs. Vendors usually don’t reveal these charges until you make the initial payment. Therefore, to be on the wiser side, ask if there are any charges for training, upgrades, hardware, or any other element.

- Calculate the ROI (return on investment) you want to see or will see once the WMS software is implemented. The KPIs can be anything from cost savings to productivity improvements or more.

Built for growing businesses, WareGo offers flexible pricing, modular features, and support for multi-warehouse operations, without the bloated costs of legacy systems. Get: ✅ Transparent pricing ✅ Quick deployment ✅ Real-time visibility

Contact Us Now8. Conduct a Demo and Trial

Today, most vendors offer a demo and free trial to help clients understand the user experience provided by the software. So, instead of thinking about demos or trials as a waste of time, ensure the solution fits your warehouse operations and processes well. The elements you achieve with a demo or trial include:

- You and your warehouse staff will secure a hands-on experience of the WMS to know if it fits your expectations.

- Consider real-world scenarios where you might need the ecommerce WMS software to perform, and see if it works for that.

- Ask your team and the warehouse staff about their experience with the WMS. Also, consider their expectations, suggestions, and issues they faced during the testing phase.

9. Evaluate Implementation and Integration

We have discussed the implementation cost, but the process and integration of WMS with other available systems are also important. It is better to opt for a client who answers your queries and helpfully guides you. You can ask the vendor about the following questions:

- Ask about the duration of the implementation process, if their team will manage it or you need to hire a team, if there will be a separate cost, or if it will affect the warehousing processes.

- See if the vendor supports data migration and make a plan B if they don’t, as data migration is an important element of the entire WMS implementation.

- Check if the WMS is compatible with your organization’s existing systems, such as ERP, accounting, CRM, or more.

10. Make a Decision with a Long-Term Vision

It feels like choosing a WMS is a current decision, but it is not. Investing in a WMS is a long-term decision that will forever affect your warehouse operations. Thus, making a sound and smart decision is vital. When picking a WMS software for your business, don’t just consider the features and automation you need today, but also think about what you will need 3 or 5 years later. This is especially important for small or growing businesses that expect to expand their operations soon. If you are unsure about what to seek in a WMS regarding the future, just see if the software comes with scalability and customization to adjust to industry trends and future tech like IoT, AI, and robotics. Future-proofing your investment is a wise decision and saves you from wasting time and money.

Why WareGo Could Be the Right Choice for Your Business?

You have a complete WMS checklist of requirements, and selecting a wms is a lot easier now. If your next step is to go through software options to pick one you want, we encourage you to consider WareGo, a well-known WMS software that stands out and works for all industries. With a cloud-based self and a list of high-end features, our WMS solution is good at offering:

- No implementation charges and a convenient process

- Accurate real-time tracking of inventory

- Scalable architecture that can grow as the business grows

- Minimum training required thanks to a user-friendly interface

- Dedicated support for updates and maintenance throughout

WareGo serves businesses and enterprises of all sizes. Whether you are just starting out, want to upgrade your WMS, or simply want your high-end operations to become more manageable, our software application is all set for that.

With a digital rating of 4.8, WareGo checks all boxes of efficiency, accuracy, and automation that a business seeks from a top-notch wms at affordable rates.

If you’ve made it this far, you're clearly serious about finding the right solution. Let us show you how Warego can make your warehouse operations faster than you think.

Talk to a WMS Expert TodayConclusion:

The journey of reviewing wms types and selecting the best one is different for every business. While guides on the internet make you feel like it’s about ticking the boxes of features to find the right WMS, it is not always like that.

When you are on the way to finding WMS software for your business, it is about finding a solution that fits in your workflow, aligns with your team, and empowers your growth plans. A great WMS choice will not feel like a burden, and it will work behind the scenes to make your daily warehouse operations, from receiving to delivery, run smoothly.

So, when making this huge decision, do not hurry. Pause, take your time, and ask questions that feel uncomfortable, like, does this WMS solution align with my vision for the next 4 to 5 years ahead? Questions, reviews, demos, and free trials will help you a lot in making this critical decision.

Remember, while wms are built for warehouses, not each one of them is made for you, and you need to find the one that fits your end-to-end needs.

If you want to explore and consider a WMS software solution with real business needs and scenarios in mind, we recommend learning about WareGo WMS benefits.

FAQs

How to choose a WMS system?

When you choose a WMS system, your main goal is to make sure it offers scalability and future growth. Every business grows with time, and operations become complex, extensive, or simply add, so in order to stay ahead of it, select a WMS that has the potential to grow with your business. This way, you will be sure that your future needs will also be taken into account.

What are the four types of wms?

The four main types of wms are standalone WMS, supply chain management module, enterprise resource planning (ERP) module, and cloud-based platform.

What is the 5 essential warehouse management process?

The 5 essential warehouse management processes are the receiving process, allocating locations, picking products, packing them, and ultimately shipping. These processes also include end-to-end inventory management with full control over quality to add efficiency to operations and optimize them.

What are the key features of a wms?

The key features of a wms include:

- Inventory Management

- Warehouse Location Management

- Goods In Processes

- Order Management

- Shipping Management

- Order Picking and Packing

- Returns Management

- Integrations

- Mobile Functionality

- Reporting and Analytics