To stay competitive, you need a WMS at the core of your warehouse operations. With a good WMS, you can stay ahead of your rivals, cut costs, and boost efficiency. The WMS has emerged as a vital tool for simplifying complex inventory.

So what are the different types of wms?

Discover the pros and cons of each to understand which type is best suited for your business requirements.

The right kind of warehouse management software can optimize your daily operations to drive success.

Table of Contents

What is a WMS?

In simple words, a WMS is a software platform that manages all aspects of your warehouse. You can use this software to manage your inventory, optimize your warehouse processes, utilize storage space, and so much more. Think of it as a user-friendly dashboard that simplifies complex warehouse operations.

Here are just a few WMS benefits:

- Maintaining optimal stock levels with smart forecasts

- Reducing high inventory costs

- Avoiding stockouts and overselling

- Syncing inventory data with your business systems

- Automating order fulfillment, customer returns, stock reordering, billing, invoicing, and other key processes

- Reducing human errors (via automation)

- Accelerating order fulfillment through automation

- Organizing inventory optimally to speed up operations

- Reports and analytics for insights

And there are many more benefits besides. Due to the numerous benefits, no serious business can operate without a WMS.

But how to choose a wms that best fits your needs?

Learn about the different types so you know which one is most relevant for you.

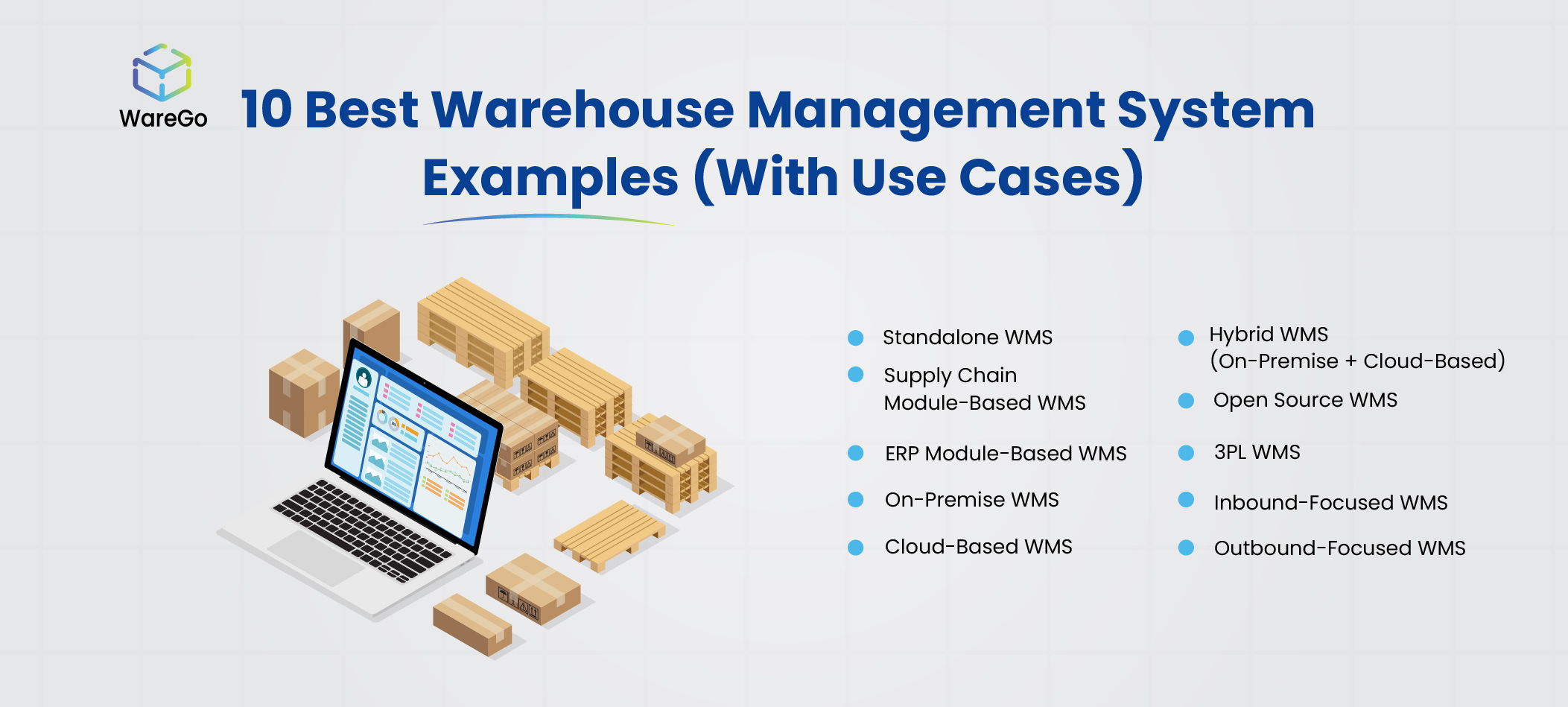

Different Types of WMS

WMS platforms can vary greatly according to features, size, and complexity. As a result, there are various types of WMS. Explore these categories to choose the best type for your business:

1. Standalone WMS

A standalone WMS is designed purely for inventory management. The software handles labor, warehouse, and order management to facilitate efficient inventory management. A good standalone WMS can integrate easily with widely adopted business tools like ERPs, CRMs, ecommerce platforms, and more. The software is suitable for SMEs with limited budgets that don’t want costly features beyond warehouse management.

Since a standalone WMS is a highly specialized tool, it offers more advanced warehouse management than other systems like ERP modules.

WMS implementation is a key issue here, as it can cost huge sums, take several months, and result in disruptions.

Pros

- Highly advanced warehouse management features

- Strong customization potential

- Fast performance

- Allows full control and ownership

- All sensitive data can be stored on-premises

Cons

- Much higher upfront costs

- Requires new IT equipment and relevant experts

- Some systems don’t sync easily with ERPs, CRMs, etc.

- May not scale readily with fast-growing operations

2. Cloud-Based WMS

A cloud native WMS is installed on remote servers, which you can access via the internet. It is ideal in many ways since you don’t have to invest upfront in costly IT equipment to run the software. Nor do you need to hire experts who will manage this IT equipment. Likewise, you don’t deal with troubleshooting since this is the responsibility of the cloud WMS vendor.

You pay only for those features that you need. The system is highly scalable and can therefore keep pace with fast-growing businesses. You can access the cloud WMS anywhere, anytime.

Pros

- System accessible anywhere, anytime

- Very fast setup

- No heavy investment in new IT equipment and experts

- Budget-friendly and affordable

- Scales easily with fast-growing operations

- WMS vendor handles all security updates

- Very high data security (backups, firewalls, encryption)

- Strong integration with common business tools

Cons

- Internet availability is a must

- Complete ownership is not possible

3. Integrated WMS (ERP Module)

An integrated WMS is part of an ERP (enterprise resource planning software). A key benefit is how well this WMS integrates with the whole system. Warehouse and inventory data can be automatically transferred to all other modules in the ERP, including financials, procurement, demand planning, transportation management, and more. Hence, the ERP operates efficiently due to its comprehensive visibility of the supply chain.

Pros

- Integrates out of the box with your ERP

- Easy to deploy

- Simple user interface

Cons

- Lacks advanced warehouse management features

- Not suitable for complex warehouse management

- Vendor lock-in

- Fewer customization options

- Less innovation than specialized WMS solutions

4. Supply Chain Management

The WMS may have additional modules that give it a full supply chain management capability. These modules may include demand planning, transport management, reporting, and analytics. Thanks to these powerful features, the scope of the WMS expands greatly, making it a supply chain management suite.

Since the suite has many features for the supply chain, beyond just warehouse management, it is a powerful tool for simplifying logistics as a whole. However, these features come at a price.

Pros

- Full-featured system for effective supply chain management

- Works well for complex logistics operations

- Helps with regulatory compliance

Cons

- Highly advanced features may not be needed by all SMEs

- Implementation is often complex

- High upfront investment

- Vendor lock-in

- Fewer customization opportunities

5. Industry Specific WMS

These are highly specialized WMS solutions that are engineered to meet the unique requirements and challenges of certain industries. For example, a pharmaceutical WMS may have temperature control, first-in, first-out stock rotation, batch and lot number tracking, and other critical features for the pharmaceutical industry. These WMS solutions are designed to help their respective industries meet strict regulatory requirements. 3PL, e-commerce, and retail WMS are other such examples.

Pros

- Facilitates industry-based regulatory compliance

- Ideal for industry-specific requirements

- Heavy customization may not be necessary

Cons

- Not flexible beyond a specific industry

- Costly

Say no to servers and delays, and opt for time-efficient control from anywhere, anytime. WareGo offers the power to control inventory, orders, operations, and more in an efficient and flexible way without any infrastructure headache.

Start a Free DemoIs a WMS Worth It for You?

An inventory management system can help you resolve all kinds of stock management problems. Chances are, you may be facing some of these problems and want a viable solution for the same.

The best wms software companies can provide a wide range of benefits for your warehouse and logistics operations.

Accurate Inventory

A WMS helps you to accurately track inventory. This means you know the exact count of each SKU. No more stockouts, overselling, or high inventory levels. The WMS can reduce human errors and ensure highly accurate inventory counts thanks to automation.

Highly Organized Inventory

Organizing inventory becomes so much easier. Since the WMS gives you the exact location of each SKU, you don’t waste time searching for misplaced inventory. This means fast order fulfillment.

Smart Inventory Allocation

The right stock is also kept at the right place at the right time. Fast-moving inventory is placed closer to your workers, so less time is spent retrieving these high-demand items. Inventory is also allocated intelligently across multiple warehouses so that shipping times and distances are minimized.

Simple Returns

Customer returns are simplified. You don’t have to waste time processing returns since a good WMS automates it.

Automation for Key Functions

Automatic stock reordering prevents stockouts. You also save time and effort this way. Timely automatic alerts and notifications can also notify you of critically low stock levels.

Invoicing and billing your suppliers and customers becomes much easier thanks to automated workflows.

Optimized Storage

The WMS helps you to utilize your valuable and limited warehouse space more effectively.

Smart Labor Allocation

You can also allocate your labor force effectively to maximize their productivity.

Omnichannel Support

Syncing inventory across multiple sales channels becomes effortless. This is especially vital if you sell on different ecommerce platforms. There are no stockouts, overselling, or wrong inventory counts to deal with.

Real-Time Updates

Real-time updates help you to take prompt action. Full visibility means you are fully informed about your entire inventory.

Fleet Management

Fleet management allows you to make the most of your valuable transport assets.

Powerful Integration

Integration capabilities allow the WMS to share inventory data with all your business systems. Your business ecosystem becomes a unified intelligent unit that can perform exceptionally well thanks to the availability of inventory information.

Reports and Analytics

Instant reports and detailed analytics give you strong, actionable insights that can greatly enhance your efficiency and boost profit margins.

Smart AI tools analyze your demand patterns to forecast optimal inventory levels accurately.

Streamlined Collaboration

The supplier portal helps you coordinate effectively with your supply chain partners and thus accelerate order fulfillment. The customer portal facilitates customers to reorder, follow order status, initiate returns, provide feedback, and other key features that greatly boost their user experience and satisfaction. You can turn buyers into loyal customers this way.

Forms and Documents

Well-designed forms, such as customer feedback forms, supplier order forms, complaint forms, and company documents, as well as transactional reports, greatly assist your workflow.

Barcode/RFID Support

Picking, packing, and shipping can proceed at high velocity with built-in RFID and barcode scanning support.

It is easy to see that WMS suites have a vast spectrum of functions and features that extend a wide range of logistics benefits. You can take your order fulfillment speed to new heights with a robust WMS.

The chaos of managing multiple clients at once with no errors is a hard thing to achieve, but WareGo’s 3PL WMS is designed to do exactly that! Be it real-time tracking of inventory, automation of billing, management of customer portals, or more, our WMS has everything to scale with confidence.

Start with a 3PL WMS SoftwareUnlock True System Potential With a Smart WMS

A proven strategy for greatly enhancing operational performance is to integrate your WMS with other business systems like your ERP, CRM, ecommerce platforms, and other tools. With strong integration, your WMS can share inventory data easily with all your business systems. No need for manual data entry, which is both time-consuming and error-prone.

With seamless synchronization, your ERP, CRM, ecommerce platform, and other systems can be easily updated in real-time with the latest warehouse and inventory information. Hence, your system is consolidated into a highly functional, flexible, and intelligent ecosystem that minimizes human effort, cuts errors, and boosts productivity. In other words, the system works for you, not the other way round.

At WareGo, we offer cost-free consultations to clients, helping them make a WMS decision that works perfectly for their 3PL, eCommerce, Manufacturing, or wholesale business.

Contact Us NowKey Factors to Consider When Choosing a WMS

Your WMS should align with your warehouse requirements, scale, and complexity. User-friendliness, integration capability, and automation tools are other key features to address.

WareGo’s WMS is engineered to efficiently handle warehouse operations for businesses of all stripes, from small retail outlets to fast-growing enterprises.

You should get in touch with our experts to find out what its features can do for your business.

WMS for Managing Key Processes

WMS can streamline key processes such as picking, packing, receiving, shipping, storage, and more. That is, all key warehouse tasks are covered. The entire inventory cycle, from receiving purchases to dispatching customer orders, is facilitated.

Real-Time Inventory Management

Responding effectively to inventory and warehouse challenges as they arise becomes much easier with real-time information. A robust WMS solution can give you 3600 visibility of warehouse operations with real-time updates, so you are always aware of what’s going on. This is a true game-changer for greatly improved management, performance, and efficiency.

Automated Order Fulfillment

Automating several key tasks is vital to boost productivity, such as automatically reordering and replenishing low stock. Likewise, you need automatic updates to stock levels when sold goods are returned. Plus, when selling inventory across multiple ecommerce platforms, you need automatic updates to stock levels so that you don’t end up overselling or face stockouts.

Hence, many key functions require automation to reduce human effort and errors. When a smart WMS does the hard work for you, your productivity and accuracy go up dramatically.

Actionable AI-Powered Insights

Smart tools in a WMS can analyze demand patterns and inventory movement to forecast optimal inventory levels. This reduces stockouts and lost sales. High inventory is also mitigated along with high associated costs.

Instant reports and deep analytics provide valuable insights that can streamline your warehouse workflow.

Bid farewell to limitations and complexities with WareGo. Whether you are connected with a single warehouse or a distribution center managing global supply, WareGo has a flexible, scalable, and adaptable solution that meets diverse warehousing needs. No more juggling between standalone, inbound, outbound, or 3PL WMS!

Get Started NowConclusion

As we conclude our blog post, we’d like to add that choosing the correct warehouse management solution for your operations is a difficult task, especially when different types of warehouse management systems are available in the market. However, you can not deny the fact that learning each type is beneficial for knowing how to choose a wms that is sound and cost-effective in the long run. For a takeaway, remember to pick a WMS that serves the current needs of your business and also has the potential to scale, adapt, and perform well once the operations grow in the near future.

FAQ’s

What are the most popular WMS?

WareGo is growing fast in popularity as a trusted WMS choice since it effectively addresses the needs of businesses across various industries. Other popular choices include Manhattan Associates, Blue Yonder, Oracle NetSuite, SAP (Extended Warehouse Management), Fishbowl Inventory, Infor WMS, and Microsoft Dynamics.

What are the different types of warehouse management solutions?

There are five different types of warehouse management solutions:

(1) Cloud-based, (2) Standalone, (3) Integrated ERP module, (4) Supply Chain Management (SCM) suite, (5) Industry-specific WMS.

How many warehouse management solutions are there?

There are at least five different types of WMS as explained above. The most popular fast-growing category is cloud-based, as it has very low upfront costs, is simple to use, and is easy to scale. Hence, it’s perfect for SMEs. WareGo is one such choice.

Which type of WMS is best for my business?

The type of WMS you need depends on your unique warehouse requirements, complexity, and scale. That said, the cloud-based model of WareGo is perfect for scaling with your growing business and simplifying inventory, no matter how complex it is. The pricing model is transparent and cost-effective, starting at just $449/month. You get enterprise features at knockdown rates, which are hard to find anywhere else.

What are the 4 types of WMS?

The 4 types of WMS include standalone WMS, WMS module in a supply chain management software, WMS module inside an ERP system, and a cloud-based SaaS WMS.