Inventory and demand planning are key processes that help businesses balance supply with customer demand. Demand planning forecasts what customers will buy, while inventory planning ensures the right products are available at the right time. Together, they reduce stockouts, avoid overstocking, and keep operations running smoothly.

In this simple guide, we will explain the main ideas you need to be aware of for planning your inventory via accurate demand forecasts.

You will understand why demand and inventory planning matter so much, the factors that go into this process, and how it leads to supply chain optimization.

We will be discussing how technology has proven to be a game-changer for inventory planning and demand forecasts, and how inventory management software can take your business to the next level.

Let’s dive in.

Table of Contents

Demand and Inventory Planning – Simple Summary

Demand and inventory planning help you maintain the correct stock level that fulfills demand without:

- Stockouts – this leads to lost sales.

- Unsold Stock – this is a wasted investment.

Optimal stock levels thus boost profits.

Demand Planning – the Details in Simple Words

Demand planning and inventory management keep your inventory levels at the sweet spot – neither too much nor too little.

This is often referred to as just-in-time inventory.

You don’t want your stock to be too low because, without enough stock to fulfill demand, you must turn away customers, end up with lost sales and dissatisfied customers due to low inventory levels.

Also don’t want stock levels to be too high. You end up with unsold stock that no one wants to buy. There are also high storage costs for excess inventory.

In short, both excessive and low stock levels can result in significant losses.

Hence, it makes sense to maintain optimal inventory levels to avoid the high costs of excessive and insufficient inventory levels.

However, this is easier said than done.

Arriving at optimal inventory levels requires in-depth demand and inventory planning, where you must analyze previous customer demand patterns and current market trends to determine the right amount.

AI tools are available in capable systems like WareGo to help you determine optimal inventory levels.

Optimal stock levels can be variable. They can vary by season and the time of the year. Hence, demand and inventory planning can be challenging.

Demand planning in supply chain management entails determining what kind of goods you need and how much of each type you should buy. In addition, you must buy these goods at the right time and store them in the right place as well. All this is necessary for optimized inventory processes that accelerate fulfillment and reduce costs.

Inventory planning is also crucial for enhancing cash flow and scaling operations safely.

The Difference Between Inventory Planning and Inventory Management

Though used synonymously, there is a fine difference between the two.

Inventory planning is actually a subset of inventory management. Monitoring, processing, and, of course, planning for your inventory are all key components of inventory management techniques.

Inventory planning itself entails looking into

- Historical data

- Current information

- Future trends

To determine how much inventory to buy. And when to buy them.

Another key aspect of inventory planning is allocating inventory to the right place at the right time. So, if you see high demand for certain goods from a particular region, you will want to store your inventory in this region for fast delivery. You will also like to allocate inventory in the right amounts to the proper sales channels.

Previous customer demand patterns are beneficial for allocating inventory to the correct locations and channels.

Inventory management aims to reduce inventory costs and expedite order fulfillment by utilizing accurate and up-to-date stock data. Inventory management is also known as inventory control. As their names imply, they involve controlling and managing your inventory.

How Demand Differs from Sales

In an ideal world, the words “demand” and “sales” should have identical meaning – the product volume you expect to sell. However, there is a very practical reason why the two terms are not the same.

Demand refers to how much of a product customers want. Sales reflect the product volume that is actually sold. As you can see, the demand can be greater than sales. Since sales do not always satisfy demand, the two terms can refer to different quantities.

So, while sales can be easily quantified, doing so for demand is not that straightforward.

Why Your Business Needs Demand and Inventory Planning

Having understood the key terms and ideas, you can now take a deep dive into planning and its benefits in particular. Here is what businesses gain from good planning.

1. Accurate Revenue Forecasts

Having realistic expectations of revenue is crucial, as it indicates whether there are investment opportunities or not. You can use this information to guide your investment and operations. This way, your money and hard work don’t go to waste.

Demand planning is a crucial tool for developing viable business plans that yield positive results.

Demand planning effectively utilizes historical data to forecast future trends. For example, if spending $10 on ads leads to the sale of 5 items, you can reasonably expect $20 in ad spend to generate the sale of 10 products.

Of course, demand planning may not be that straightforward, as certain factors can yield unexpected results. Hence, planners should take into account all such factors that can impact our predictions.

To this end, there are two approaches: top-down forecasting and bottom-up forecasting.

Top-down forecasting involves the big picture. This method utilizes market conditions, economic forecasts, industry growth rates, and other key factors to establish sales targets.

Bottom-up forecasting, on the other hand, considers the organization’s own past sales figures, SKU data, inventory turnover, and so on to arrive at a sales target.

You often need a combination of these two approaches to determine realistic sales targets.

Such planning is necessary for creating a business plan that sets the right goals for an organization’s various departments.

Profits generated from this plan are vital for funding key business expenses, such as advertising, overheads, and rent. Hence, accurate forecasts are vital for meeting both fixed and variable costs.

2. Better Customer Experience

Precise inventory and demand planning are paramount for a memorable customer experience. You can buy just the right amount of inventory to satisfy demand without bearing the cost of unsold goods.

With an accurate inventory and demand forecast, you can have enough stock to fulfill all customer orders. However, in the absence of such forecasts, you may run into stockouts and turn away your customers. This, of course, leads to dissatisfaction, and you end up losing valuable customers this way.

But with good inventory planning, you almost always have enough stock at hand to fulfill all customer orders. With consistent order fulfillment, you can build trust with your customers, besides providing them with a good brand experience. Hence, your customers keep coming back for more. Strong inventory planning is therefore vital for retaining customers.

Your customers may even recommend you to others as a reliable supplier. Hence, you can expand your customer base this way.

3. No Overstocking or Understocking

In the absence of robust demand and inventory planning, you run the real risk of having too little or too much stock on your hands.

With insufficient stock, there is a strong risk of stockouts, which lead to lost sales and dissatisfied customers.

With excessive stock, you end up with lots of unsold goods, which is a wasted investment. This is in addition to high holding costs.

So, both insufficient and excessive stock levels are detrimental to the bottom line. You can avoid both these scenarios by determining optimal stock levels via demand and inventory planning.

This is achieved through inventory and demand planning, which helps reduce inventory holding costs and maximize profitability across various channels. You can estimate demand using safety stock calculations and lead time to determine how much stock you need at a given time.

4. Data-Driven Decisions

What if you want to reduce your marketing budget or hire more workers? Without a precise forecast, it becomes much harder to make good business decisions.

But with reasonable forecasts, you can make data-driven decisions that help grow your business and meet challenges that come your way.

5. Aligning Business Functions

With good demand and inventory planning, you can set targets for your business functions. This aligns your business functions in the pursuit of common goals. Finance, marketing, product development, supply chain, and other functions can then work in harmony to accomplish your objectives.

For example, with a specific demand forecast, supply chain managers will know how many suppliers they will need to coordinate with and how much product volume needs to be supplied.

If the current group of suppliers is insufficient, managers can then consider reaching out to other external suppliers. This way, everyone can get ready for what is to come once they have a pragmatic forecast.

6. Market Readiness

Markets can change dramatically; therefore, it is essential to keep track of market trends and conditions. Inventory and demand planning require an understanding of these key factors.

Hence, with effective demand planning, businesses can be prepared to capitalize on opportunities and address challenges that arise, such as supply chain disruptions.

7. Performance Benchmarks

Exceeding or falling short of forecasts gives a reasonable indication of how well a business is performing.

If the business falls short, it can analyze the reasons for not meeting its targets. The company can implement these findings to improve its performance in the near future.

But when the business meets its targets and exceeds them, it can then decide to reward its management, sales team, and other stakeholders. The level of reward will be based on the extent to which performance exceeded the forecast.

Is WareGo the right demand and inventory planning tool for your business? Find out with a 100% FREE trial.

Start My FREE Trial!Why Planning Matters

Failing to plan is planning to fail. This is a well-known saying rooted in reality. That is why no serious enterprise moves forward without diligent sales and operations planning.

From operations to HR to finance, all departments need solid forecasts and targets to measure their performance. Demand and inventory planning not only provides targets but also supplies valuable insights that can be of great help to business functions.

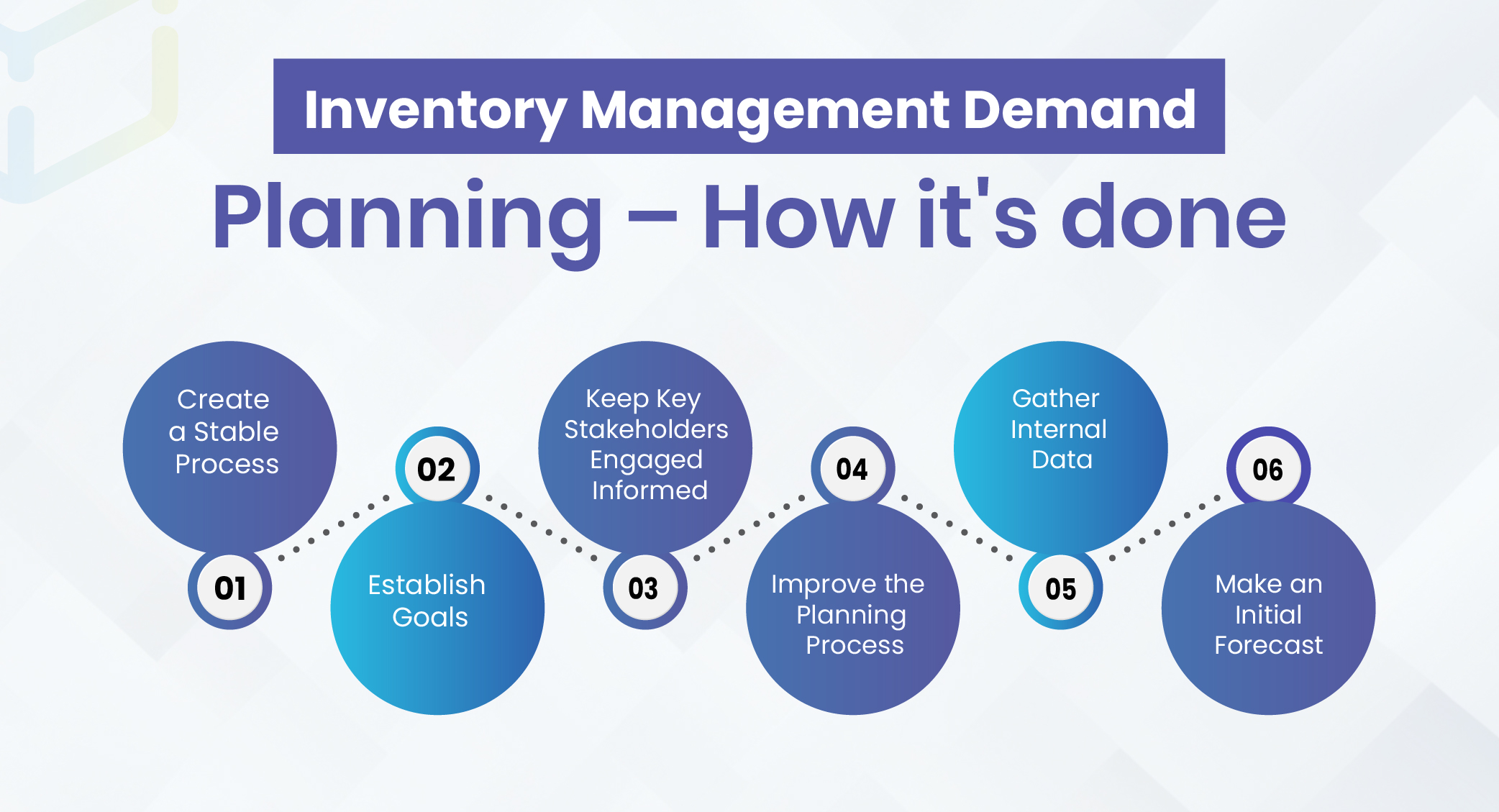

Inventory Management and Demand Planning – How it’s done

Optimizing inventory levels, intelligently allocating inventory, and streamlining inventory operations all start with thorough inventory planning and demand forecasts.

Here are the steps you should implement for robust inventory management and demand planning.

1. Create a Stable Process

You need to create a process that remains consistent. The process will require real-time inventory tracking, feedback from your stakeholders, and strong alignment across all business functions.

Successful planners are not just concerned with accurately guessing inventory demand. They aim to create a process that works equally well in challenging circumstances, as well as in stable conditions.

In short, you need a plan to plan well. This is a strong insight for staying ahead of the curve.

2. Establish Goals

Plans have just one purpose – to achieve one or more goals. Hence, you must have a good idea of what it is that you are planning to achieve.

- Do you want to meet a specific sales target?

- Are you trying to retain more customers?

- How much should your return on investment be?

These, and other such fundamental questions, will no doubt have a strong effect on your business strategy, product/service offering, inventory levels, and so on.

Since your inventory will be a key investment, you must decide matters like selling locations, overheads, inventory control techniques, and much more.

3. Keep Key Stakeholders Engaged and Informed

Engaging key stakeholders and keeping them informed is a vital step for making better forecasts and making continuous improvement in this regard.

You will need to include the right personnel from sales to finance. These professionals will provide you with key requirements and insights that can guide your planning procedure. Establish a proper channel for communication to drive collaboration and to enhance the planning process.

4. Improve the Planning Process

Plenty of trial and error will be needed before your forecasts can even start getting close to actual sales and other such key figures.

Be ready for the overwhelming nature of demand and inventory planning. A big reason for this is that forecasts can never be 100% accurate. What we often refer to as accurate forecasts are actually less far off from the truth than poor forecasts. But with the right processes, tools, and people in place, you can actually get better with this.

5. Gather Internal Data

You will need a strong foundation for making good forecasts. To this end, you will need to pull both numerical data and qualitative information related to your core business functions. These include.

- Inventory data

- Sales figures

- Marketing activity

- Promotions like discounts and special offers

6. Make an Initial Forecast

With your key data in place, you can analyze it to make a reasonable forecast.

Understand how each product is performing and what effect price is having on sales.

Instead of just seeing the overall sales figure, look into the sales performance of each SKU to uncover patterns.

In particular, you will need to understand which product categories constitute most of your sales.

When searching for patterns, you will need to discover what effect individual product categories are having on each other.

Here are specific patterns to watch out for.

- Cannibalization – to give you an example, suppose a black shirt constitutes 20 percent of total sales. If you introduce a new product, you find that both this new product and the black shirt contribute 20% to sales. This is how product cannibalization works. It happens when introducing one product hurts another product’s performance.

- Substitution – this is when customers switch from your brand product to another similar product from a different brand. This happens quite often due to pricing.

- Attachment – it refers to how the sale of one product relates to the sale of another related product. For example, you may find that one hair mask is sold for the price of four shampoos. That attachment ratio here is 4:1. So if you are expecting a rise or fall in shampoo sales, you can guess the sales figure for the hair mask.

Seasonal variations in demand can also impact product sales. At certain times of the year, like the holiday season, we often see a spike in sales.

Get your free demo to see our cutting-edge platform live in action.

Start My FREE Demo!Factors That Affect Demand and Inventory Planning

Certain factors will have a strong effect on your planning strategy. This will comprise the foundation of your demand and inventory planning. Here are the factors to consider.

1. Profit Margins

The minimum acceptable profit margin must be figured out. This, of course, has a strong effect on pricing.

Pricing is a key factor that often has a strong effect on product sales. Hence, pricing should be at the core of your forecasts. You should have a rough idea of how much sales will rise or fall with an increase or decrease in price.

How much you charge for your product will directly depend on how much profit margin is needed to keep your business viable. Inventory and demand planning are necessary for achieving financial goals.

2. Supply Chain Capability

When planning for inventory, you should give due regard to the capability of your supply chain. Your inventory and sales targets can be met only if your supply chain can keep up.

Consider the lead time necessary for replenishing stock. This is necessary for avoiding stockouts.

Understanding the speed and capacity of your supply chain is crucial for ensuring the timely fulfillment of customer orders. This will guide your inventory planning process.

Such deep understanding is necessary when launching new products or expanding your product line.

3. Business Development

As your business grows, you can expand into different locations and thus see a rise in demand. Whether you expand into a new market by either physical stores or online marketplaces, there will likely be a shift in demand, which could possibly have an effect on other sales channels you are running.

4. Customers

You can relate your historical sales performance to specific types and numbers of customers. Understanding the customer mindset is crucial for predicting demand, especially when promoting new products or facing shifts in your customer base, such as an increase in new customers or higher customer retention rates.

5. External Factors

Economic trends and competition are key factors that can influence demand for your inventory.

Taking into account the aforementioned factors can help you determine a more precise forecast that aligns more closely with reality.

Planning Accuracy and Frequency

A planner’s job is never done. They have to repeat the same process at regular intervals, typically a month or so.

Towards the end of a set time frame for which the forecast was made, an assessment is carried out for the quality of the estimates. The purpose of this is to see the extent of the variation, that is, by how much the estimates vary from the real figures for demand, inventory, and sales.

If the variance is large, the root causes need to be determined and resolved so that such issues are not repeated going forward.

Therefore, you will need to start from the beginning of the entire planning cycle. That is, you need to import the updated information to evaluate the variation between the forecast and actual numbers. You can then refine your forecast strategy after determining the root causes for diverging figures.

One thing to note is that proper tools are needed for good forecasts. Spreadsheets just won’t cut it, especially if you want quick forecasts at short intervals. You need a capable WMS like WareGo, which has built-in intelligent forecasting tools and provides complete, accurate, and up-to-date stock data.

Our friendly experts will be delighted to explain how WareGo can streamline your business.

Start My FREE Consultation!Practical Considerations for Stock Replenishment Strategy

Not only do you need to determine how much stock is required to fulfill demand, but you should also know when to order stock and in what amount. This is due to key factors like lead time, cash flow, and safety stock that strongly affect replenishment strategy.

When stock falls to a certain critical level, you will need to reorder extra stock to continue fulfilling demand. When reordering, you must give due regard to:

- Current Inventory Volume – how much stock is actually available? This will help you decide the amount of extra stock you need to acquire.

- Vendor lead time – how long will your vendor take to deliver the goods once you place an order for the same? Keeping this time frame in mind is essential for preventing stockouts.

- Ordered Goods – how many goods have you actually ordered that are on the way? This matters especially if you deal with complex supply chains handling multiple vendors simultaneously.

How Technology Optimizes Demand and Inventory Planning

Cutting-edge technology and state-of-the-art demand forecasting tools are now helping savvy companies make accurate forecasts effortlessly. Since these tools save plenty of time, money, and effort, they have become an indispensable part of the planning/forecasting workflow.

Here is how demand and inventory planning software helps:

1. Consolidates Data

You can rely on several methods to boost forecast accuracy. However, you may still be hit by certain variables that can take your planning by surprise.

A significant issue here is consistently using a consolidated data source for your planning process.

As your business evolves, data may become isolated and restricted to specific business tools you are using. You need to integrate these disconnected systems so that you have one consolidated and unified source for data that is easily accessible to all, including you and your fellow planners. This can be achieved through data synchronization, where data is exchanged seamlessly between systems without requiring manual data entry. Hence, your ecosystem becomes much faster, instantly providing the information you need.

2. More Precision

Moreover, costly human errors are reduced since data entry is eliminated when your business tools are synced flawlessly with each other.

Since data accuracy is higher, the quality of the forecast will be much better.

Your team’s productivity goes up as well.

3. Sophisticated Algorithms

Intelligent tools are now available that can do the heavy lifting for you to boost forecast accuracy. For example, WareGo has built in statistical methods and machine learning algorithms that can crunch the numbers so you don’t have to. You are then free to focus on inventory management and control.

4. Accelerated Forecasts

Leave the hard work – inventory planning – to intelligent cutting-edge tools engineered to make complete sense of data in a fraction of the time humans take. Sophisticated replenishment algorithms can process millions of data points in a flash. Needless to say, this is way faster than what the best professionals can manage.

5. Smarter Forecasts

What’s more, automation tools have a much better ability to detect patterns compared to humans.

Not just that, these AI models actually get smarter with more use. Hence, you can expect a more efficient model with each forecast cycle.

6. Inventory Automation

Besides analyzing data much faster than humans, they can also take quick action when the need arises. For example, AI can quickly detect low stock levels and automatically reorder optimal stock volumes.

7. Simplifies Complex Inventory

Carrying out inventory demand forecasting at short intervals has always been a challenge, if not impossible, for manual methods and spreadsheets, especially when dealing with numerous SKUs and suppliers. However, quick demand forecasting and inventory planning have become much easier and pain-free with automated AI-powered forecasts.

8. Mitigates Human Shortcomings

You need far more than just “gut feeling” to make good demand forecasts. Viable AI tools eliminate bias, avoid human errors, and unlock hidden trends with unmatched efficiency. To do this, they deploy sophisticated learning algorithms and sales forecasting models to give you unbiased forecasts. These proven methods are far superior to human intuition.

9. Better Management Performance

In short, you can digitize and add real value to all parts of your supply chain using the right software.

Human planners and forecasters can make good use of deep analytics and on-demand reports to discover valuable insights for their inventory. So this boosts the productivity and performance of your managers.

10. Eliminates Operational Problems

Enterprise-grade WMS can generate accurate demand forecasts to guide automated stock replenishment. This way, you won’t have to endure stockouts, lost sales, and unhappy customers. Equally importantly, you can make data-driven decisions with these forecasts and watch your business grow.

Another key advantage of an all-in-one WMS is that it lets you conduct both inventory planning and demand forecasting on the same platform. This matters because legacy tools and spreadsheets meant that these key processes were separate, resulting in data silos. With WareGo, you can unify data for both key processes into a single source of truth and watch productivity rise.

WareGo offers all the above benefits and more.

Hence, you should immediately reach out to us and find out how this demand and inventory planning software can consolidate your inventory planning, demand forecasts, and operations management.

Bottom Line

Demand and inventory planning is no doubt a complex endeavor that entails numerous variables – each of these can throw a wrench in the works and make it that much harder for you and your planners.

That is why you need the power of AI and modern technology to ease this arduous and painstaking process. WareGo incorporates proven cutting-edge technologies, including AI, to streamline the process and, most importantly, enhance accuracy.

Therefore, having a state-of-the-art demand and inventory planning tool is not an option. It is indispensable for staying ahead of the curve with your inventory.

Without delay, you should reach out to us and find out what our trusted WMS can do for you. Our friendly professionals would be more than pleased to hear from you and give you the most helpful expert advice.

Our friendly experts can outline in simple words how it all works.

Chat With Us!FAQs

What is the planning for demand and inventory?

Demand and inventory planning help you maintain the optimal level of stock to meet customer demand without stockouts or overstocking. You can thus avoid lost sales, high inventory holding costs, and unsold stock with demand and inventory planning.

What is the difference between inventory planning and demand planning?

Demand planning involves understanding how much your customers are willing to buy from you.

Inventory planning is concerned with keeping the right stock in the right amount at the right place to adequately meet customer demand. Controlling inventory through effective planning streamlines operations, expedites order fulfillment, and enhances the customer experience.

What do you mean by inventory planning?

Inventory planning is about keeping just enough inventory to fulfill demand without excess stock. It is also concerned with placing inventory at the right locations to speed up shipment and even keeping them in the correct positions in your warehouse to reduce worker travel time. Doing so streamlines inventory processing.

Inventory planning also entails:

- Making sales forecasts

- Establishing reorder points

- Managing suppliers

What are the 4 types of inventory?

The 4 types of inventory are:

- Raw materials

- Work in progress

- Finished goods

- MRO (Maintenance, Repair, and Operating Supplies)

MRO includes lubricants, cleaning products, and other such materials that support production but are not included in the manufactured product itself.